Red phosphorus photoelectrode and preparation method and application thereof

A photoelectrode and red phosphorus technology, applied in electrodes, photosensitive devices, circuits, etc., can solve problems such as narrow light absorption range, and achieve the effects of simple preparation method, simple composition and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

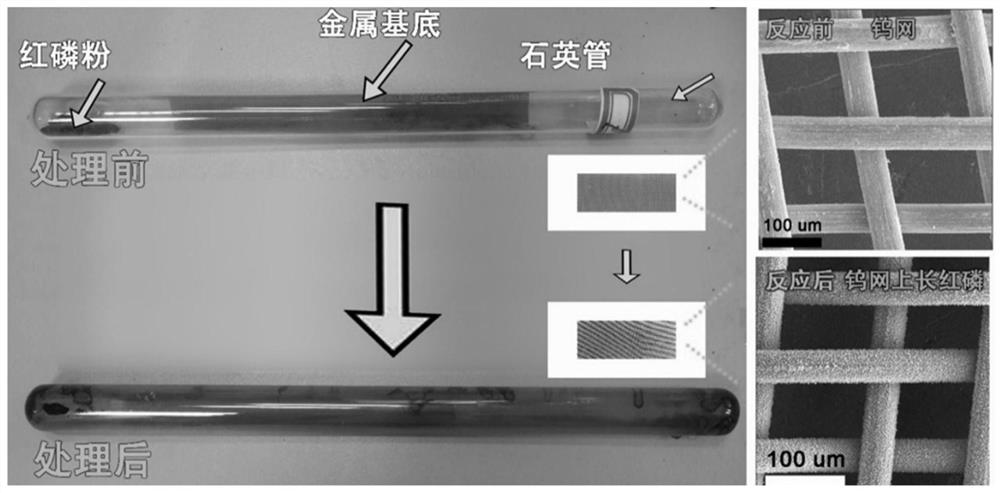

[0037] In this embodiment, a crystalline phase red phosphorescent electrode (CP / W) with a tungsten mesh substrate is prepared, and the specific process is as follows:

[0038] Weigh 200mg of red phosphorus and a metal tungsten mesh substrate with a width of 1.0cm and a length of 20.0cm, seal them in a quartz organ, and vacuumize them. Then put the quartz tube into the furnace, raise the temperature to about 550°C at a rate of 1.0°C / min, protect it for 15 hours and then lower it to room temperature at a rate of 0.1°C / min. Then break the quartz tube, take out the substrate, and wash it with water and ethanol to prepare a red phosphorescent electrode.

[0039] figure 1 It is the photo of the quartz tube before and after the heat treatment and the scanning electron microscope picture. From figure 1 It can be seen that red phosphorus is deposited on the tungsten mesh after heat treatment.

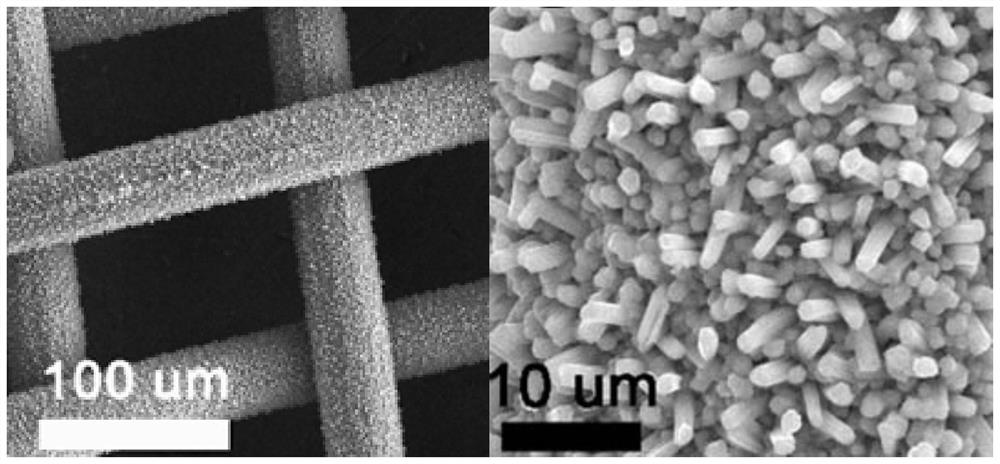

[0040] Electron microscope scanning of the red phosphorescent electrode after heat treat...

Embodiment 2

[0042] In this embodiment, a crystalline phase red phosphorescent electrode (CP / W plate) with a tungsten sheet substrate is prepared, and the specific process is as follows:

[0043] Weigh 200mg of red phosphorus and a metal tungsten substrate with a width of 1.0cm, a length of 3.0cm, and a thickness of 0.2cm, seal them in a quartz organ, and evacuate them. Then put the quartz tube into the furnace, raise the temperature to about 550°C at a rate of 1.0°C / min, protect it for 15 hours and then lower it to room temperature at a rate of 0.1°C / min. Then break the quartz tube, take out the substrate, and wash it with water and ethanol to prepare a red phosphorescent electrode.

Embodiment 3

[0045] In this embodiment, a crystalline phase red phosphorescent electrode (CP / Mo plate) with a molybdenum sheet substrate is prepared, and the specific process is as follows:

[0046] Weigh 200mg of red phosphorus and a 1.0cm wide, 3.0cm long, 0.2cm thick metal molybdenum substrate, seal them in a quartz tube, and vacuumize them. Then put the quartz tube into the furnace, raise the temperature to about 550°C at a rate of 1.0°C / min, protect it for 15 hours and then lower it to room temperature at a rate of 0.1°C / min. Then break the quartz tube, take out the substrate, and wash it with water and ethanol to prepare a red phosphorescent electrode.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com