Aqueous composition for coating grain-oriented steel

A water-based composition, grain orientation technology, applied in the direction of magnetic objects, magnetic materials, inorganic materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] Another aspect of the present invention relates to a method for preparing an aqueous composition for coating grain-oriented steel, which method comprises the above-defined aluminum cation-releasing compound, manganese cation-releasing compound, dihydrogen phosphate, A step of mixing a compound of hydrogen phosphate and / or phosphate anion, a compound releasing colloidal silica and optionally an iron cation.

[0057] An ion-releasing compound is a compound capable of releasing ions (eg, metal ions such as aluminum) in water. The ion-releasing compound may be a salt, oxide, oxalate or hydroxide.

[0058] Another aspect of the invention relates to a method for coating grain oriented steel comprising applying an aqueous composition according to the invention or an aqueous composition preparable according to the method of the invention.

[0059] According to another preferred embodiment of the invention, the grain-oriented steel is base-coated with forsterite.

[0060] As i...

Embodiment 1

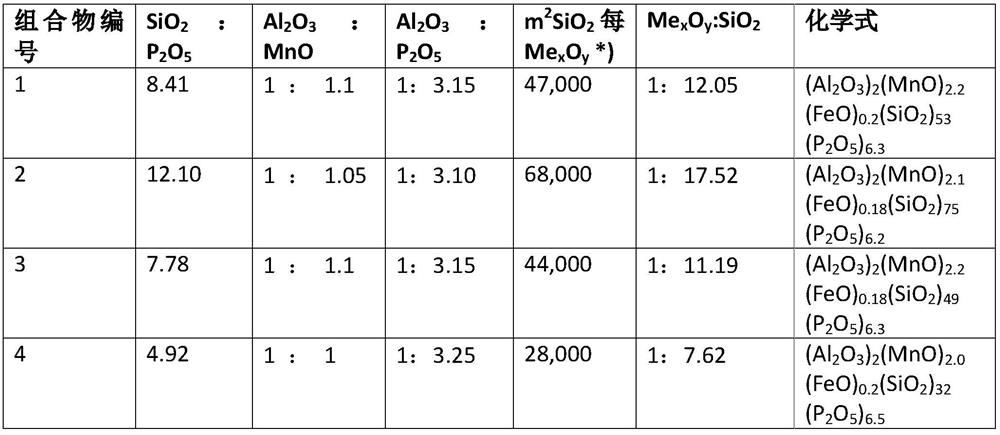

[0101] Example 1: Preparation of an aqueous composition for coating grain oriented steel

[0102] In a mixture of 400 g of 75% phosphoric acid and 135 ml of water, 78 g of aluminum trihydroxide, followed by 40 g of manganese(II) oxide and 7 g of iron(II) oxalate were dissolved to give a clear viscous phosphate-containing solution. The total weight of the resulting solution was 660 g. To 200 g of the phosphate-containing solution, 800 g of SiO with a solids content of 30% (average diameter 35 nm) was added. 2 spheres) of uncharged silica sol (colloidal silica) into a clear homogeneous preparation. The calculated composition is (Al 2 o 3 ) 2 (MnO) 2.2 (FeO) 0.2 (SiO 2 ) 53 (P 2 o 5 ) 6.3 (Composition 1).

[0103] at 5g / m 2 After being applied to a GO steel plate with a base coating (ie, a forsterite-coated grain-oriented steel plate), it was briefly dried in air and the layer was cured at 820° C. for 60 seconds.

[0104] By adjusting the stoichiometric ratios of th...

Embodiment 2

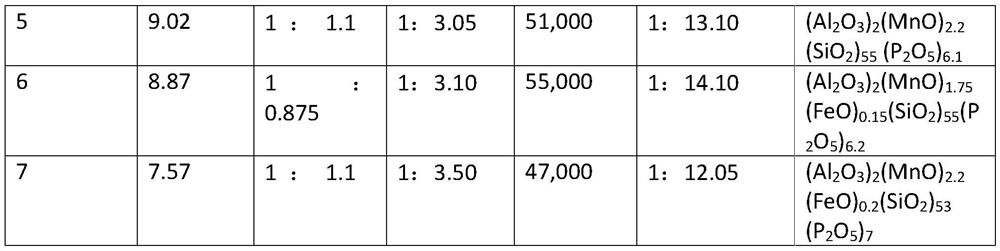

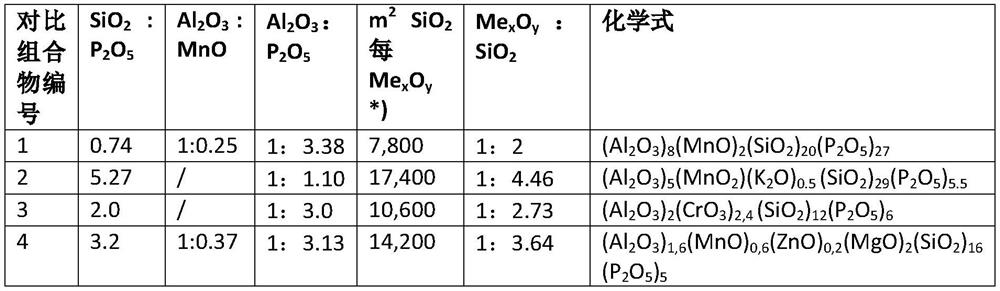

[0121] Embodiment 2: comparative composition:

[0122] In order to illustrate the advantages of the compositions according to the invention over other compositions from the prior art, corresponding tests were carried out using comparative compositions.

[0123] Comparative Composition 1 (Example B1 (Al,Mn) from WO2014 / 180610)

[0124] (Al 2 o 3 ) 8 (MnO) 2 (SiO 2 ) 20 (P 2 o 5 ) 27

[0125] Comparative composition 2 (example 1 from EP2264220Al (KMnO 4 ))

[0126] (Al 2 o 3 ) 5 (MnO 2 )(K 2 O) 0.5 (SiO 2 ) 29 (P 2 o 5 ) 5.5

[0127] Comparative composition 3 (Example 3 (Al,Cr) from DE2247269)

[0128] (Al 2 o 3 ) 2 (CrO 3 ) 2.4 (SiO 2 ) 12 (P 2 o 5 ) 6

[0129] Comparative Composition 4 (Example B3 (Al, Mn, Zn, Mg) from WO2014 / 180610)

[0130] (Al 2 o 3 ) 1.6 (MnO) 0.6 (ZnO) 0.2 (MgO) 2 (SiO 2 ) 16 (P 2 o 5 ) 5

[0131] Then, comparative compositions 1 to 4 were treated as described in Example 1 at 5 g / m 2 The amount of GO was ap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com