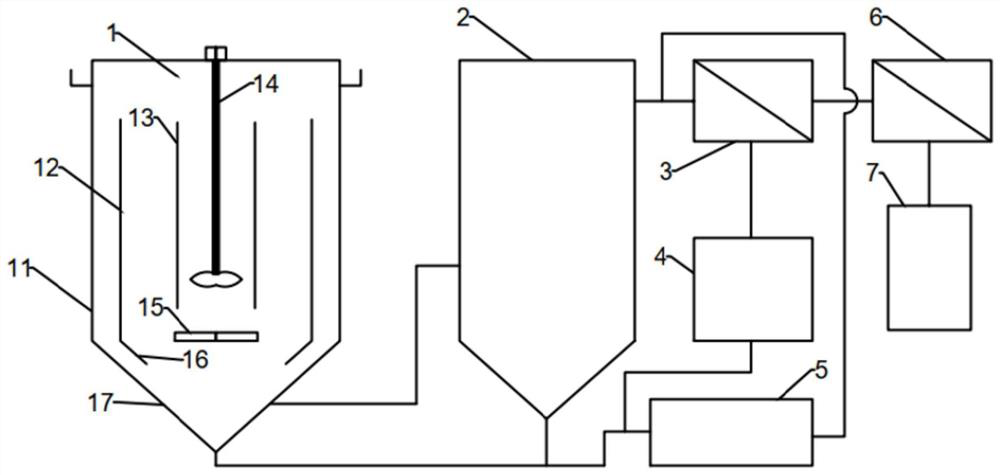

Drilling wastewater treatment system

A technology for treating system and drilling wastewater, which is applied in mining wastewater treatment, water/sewage treatment, heating water/sewage treatment, etc. It can solve the problems of difficult water quality, standard discharge, high treatment cost, etc., and achieve low oil content, complete separation, The effect of high deoiling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A drilling wastewater, COD: 1750mg / L, pH8.6, TP: 1.1mg / L, ammonia nitrogen 14.0mg / L, chloride ion content: 8450mg / L, suspended solids: 1648mg / L, oil content: 179mg / L;

[0045]The residence time in the internal circulation reactor is 20min, the effluent COD: 1140mg / L, pH7.5, TP: 0.9mg / L, ammonia nitrogen 0.6mg / L, chloride ion content: 7648mg / L, suspended solids: 145mg / L, oil content 31mg / L;

[0046] The effluent from the internal circulation reactor is transported to the settling tank for a residence time of 1.5h. The effluent of the settling tank has COD: 861mg / L, pH6.9, TP0.5mg / L, chloride ion content: 7348mg / L, and suspended solids: 11mg / L;

[0047] The effluent of the sedimentation tank enters the ultrafiltration device, and the ultrafiltration effluent COD: 164mg / L, pH7.1, TP: 0.2mg / L, ammonia nitrogen 0.1mg / L, chloride ion content: 11100mg / L; the ultrafiltration effluent enters the evaporation device for salinization evaporative crystallization treatment, and tran...

Embodiment 2

[0051] On the basis of Example 1, the oxidation tank was replaced by an electrocatalytic oxidation tank, and the chlorine ions in the ultrafiltered concentrated water were electrocatalyzed to form hypochlorite to oxidize and degrade the organic matter in the wastewater.

[0052] The electrocatalytic cell is equipped with mesh cathode and anode plates, and the anode is Ti / SnO 2 And iron plate, the cathode catalytic electrode is Ti metal electrode, the working current intensity is 10-30 amperes / ㎡ DC; the COD concentration of the effluent is reduced to 92.6mg / L, and the effluent of the electrocatalytic cell is returned to the ultrafiltration device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com