A kind of preparation method of low-melting point five-element gallium-based liquid alloy

A technology of liquid alloy and low melting point, which is applied in the field of material metallurgy, can solve problems such as the gap between gallium-based liquid alloys, achieve the effect of simple preparation method, solve the threat of environmental pollution, and have wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

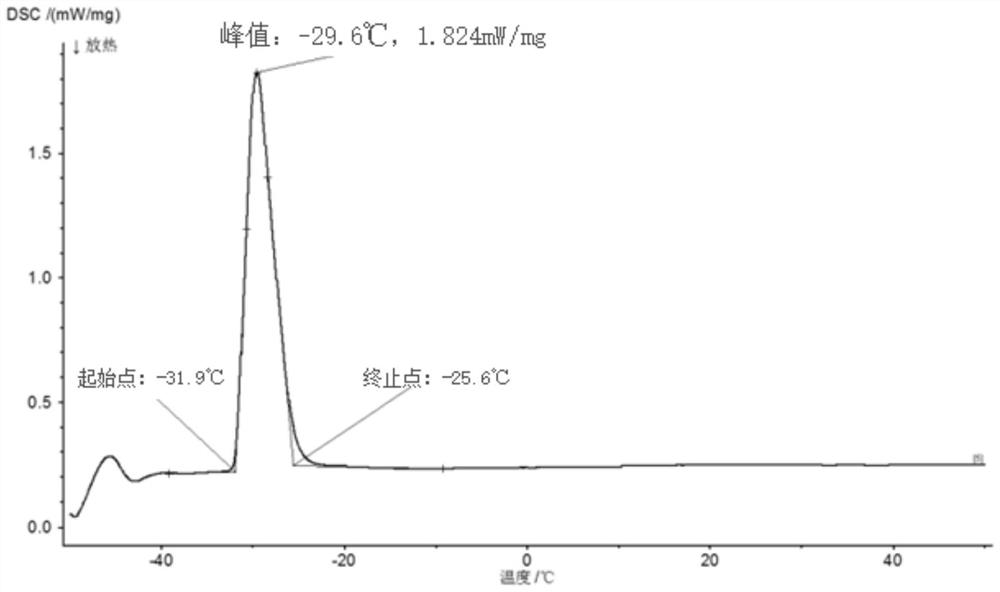

Embodiment 1

[0017] It was accurately referred to with analysis of the balance to be accurately referred to, indium 2.4420 g, tin 0.7235 g, zinc 0.0403 g and 0.0200 g of aluminum (about 0.1% aluminum content). Gallium, indium, tin and zinc first addition in graphite crucibles, and finally placed in aluminum. The graphite crucible is moved into the atmosphere, and the high purity argon protection is passed after vacuum. The temperature was warmed to 700 ° C and held for 1 h. The graphite crucible is taken out with the furnace. After standing for 2 hours, the surface oxide film was removed, and a low melting point gallium-based liquid alloy was obtained.

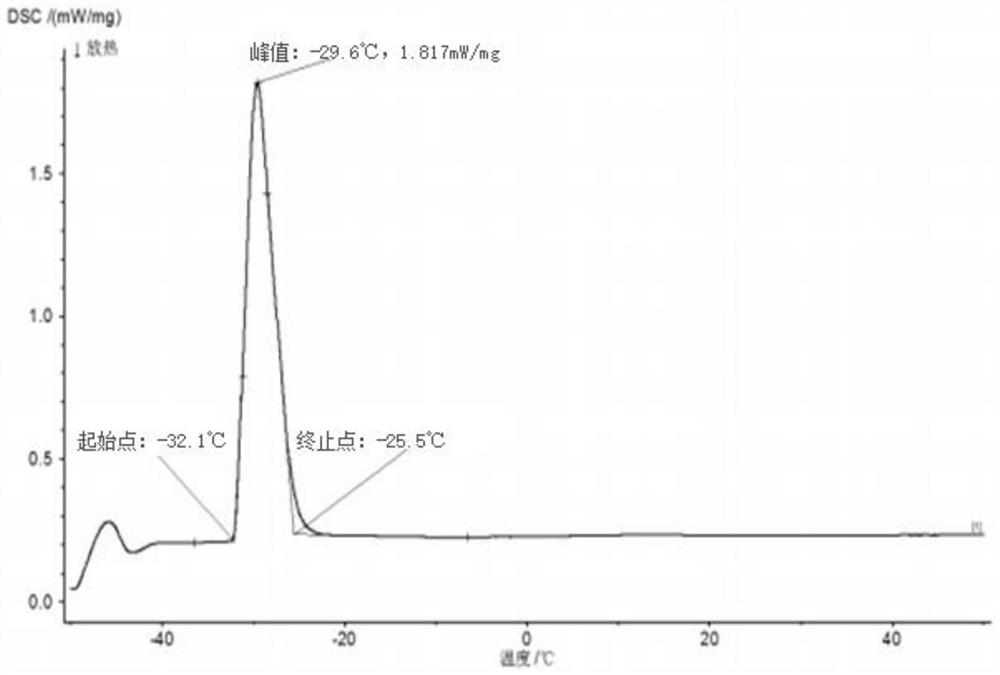

Embodiment 2

[0019] The whole bottle of raw material is first placed in a blast drying tank, warmed to 60 ° C until all melts, and weigh 50.3360 g of liquid gallium, added to the polytetrafluoroethylene crucible. Then, the analysis is accurately referred to as the analysis of 7.3210 g, tin 2.1610 g, zinc 0.1201 g and 0.0620 g (aluminum content of about 0.1%), and added to the polytetrafluoroethylene crucible containing molten gallium. Graphite rods were stirred to solid-state metal feedstocks were completely dissolved in molten gallium at 60 ° C, and the oxide film was removed after 4 h, resulting in ultra-low melting gallium-based liquid alloy.

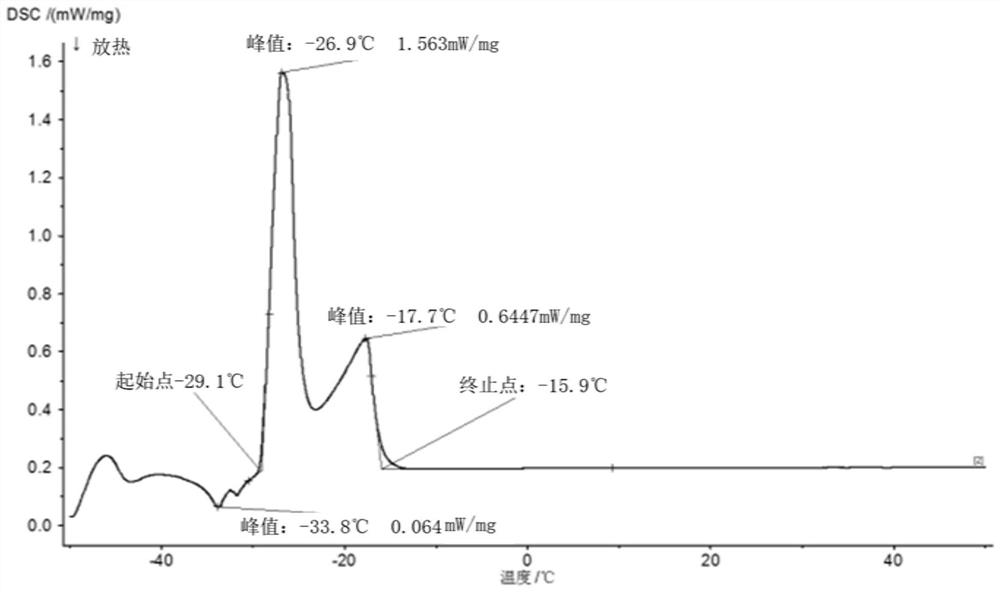

Embodiment 3

[0021] It was accurately referred to using the analysis of the balance of 5.2780 g, indium 7.3210 g, tin 2.1610 g, zinc 0.1200 g and 0.1200 g of aluminum (about 0.2% aluminum content). Gallium, indium, tin and zinc first addition in graphite crucibles, and finally placed in aluminum. The graphite crucible is moved into the atmosphere, and the high purity argon protection is passed after vacuum. The temperature was warmed to 700 ° C and held for 1 h. The graphite crucible is taken out with the furnace. After standing for 2 hours, the surface oxide film was removed, and a low melting point gallium-based liquid alloy was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com