Welding and cutting integrated control system

An integrated control system, welding and cutting technology, applied in the direction of general control system, control/regulation system, program control, etc., can solve the problems of inconvenient use and maintenance, large space occupation, high investment cost, etc., and achieve high field operation efficiency, Solve the effect of large space occupation and flexible use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

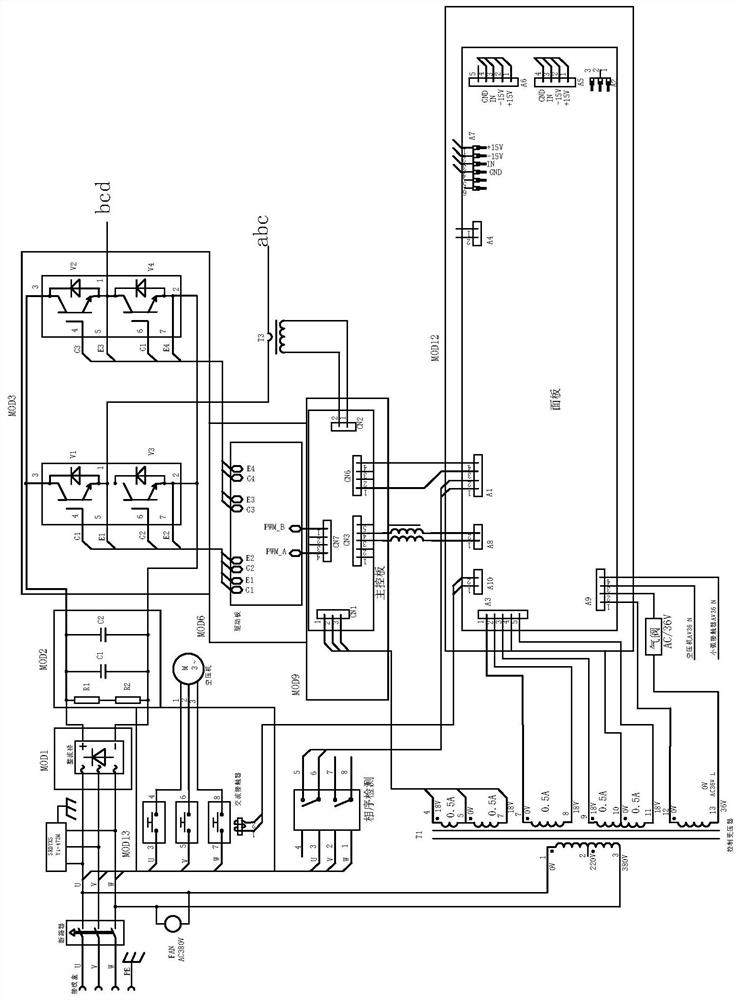

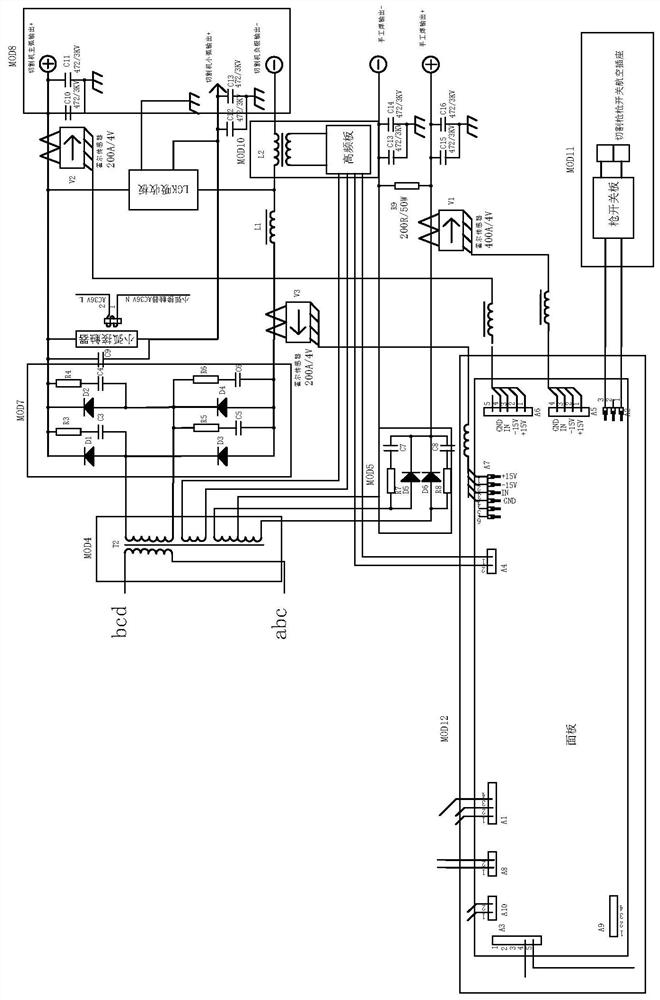

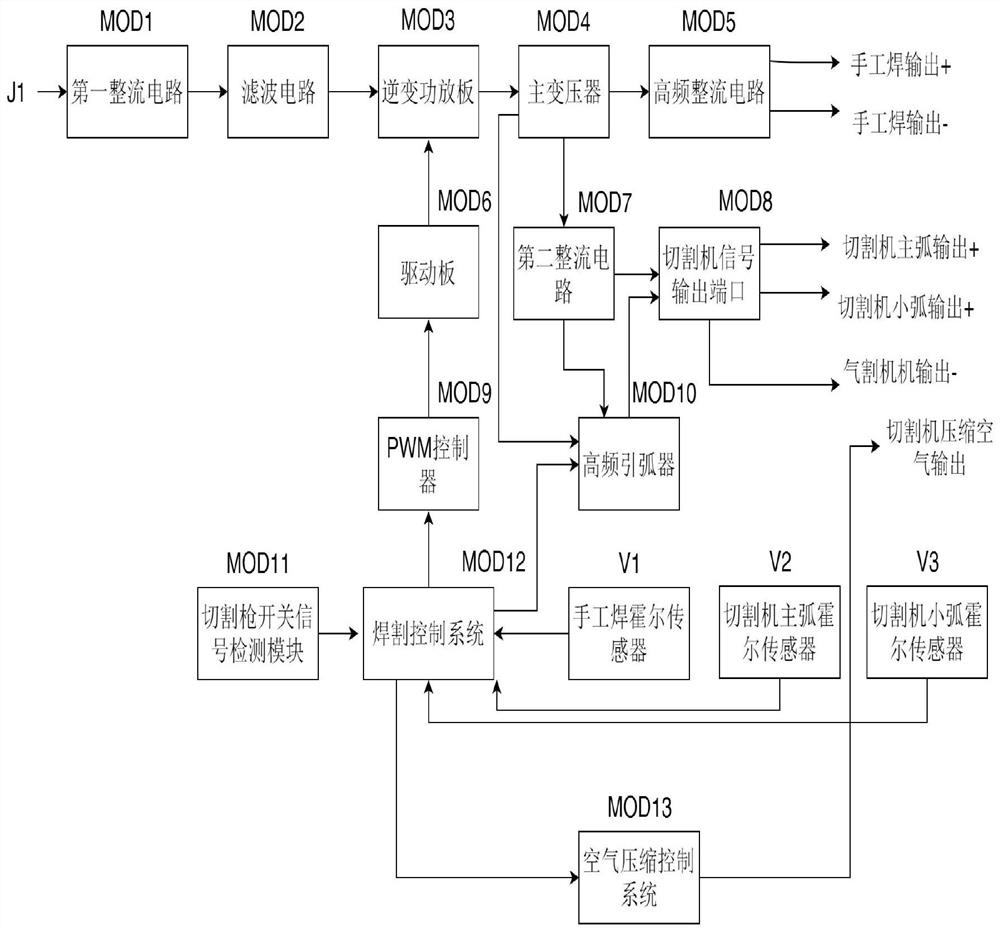

[0029] The following is attached Figure 1-5 The application is described in further detail.

[0030] The embodiment of the present application discloses a welding and cutting integrated control system. refer to image 3 , a welding and cutting integrated control system, including inverter power amplifier board MOD3, main transformer MOD4, high frequency rectification circuit MOD5, drive board MOD6, second rectification circuit MOD7, cutting machine signal output port MOD8, PWM controller MOD9, high frequency Arc starter MOD10, cutting torch switch signal detection module MOD11, welding and cutting control system MOD12 and air compression control system MOD13, the main transformer MOD4 is connected with inverter power amplifier board MOD3, high frequency rectification circuit MOD5, and second rectification circuit MOD7 respectively It is connected with the high-frequency arc starter MOD10, the drive board MOD6 is respectively connected with the inverter power amplifier board...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com