A Speed Control System of Switched Reluctance Motor with Power Factor Correction

A switched reluctance motor, power factor correction technology, applied in control systems, motor control, vector control systems, etc., can solve problems such as reducing power factor and power quality, reducing energy conversion efficiency, and unsatisfactory power quality. Power factor and power quality, the effect of simplifying control schemes, reducing control complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

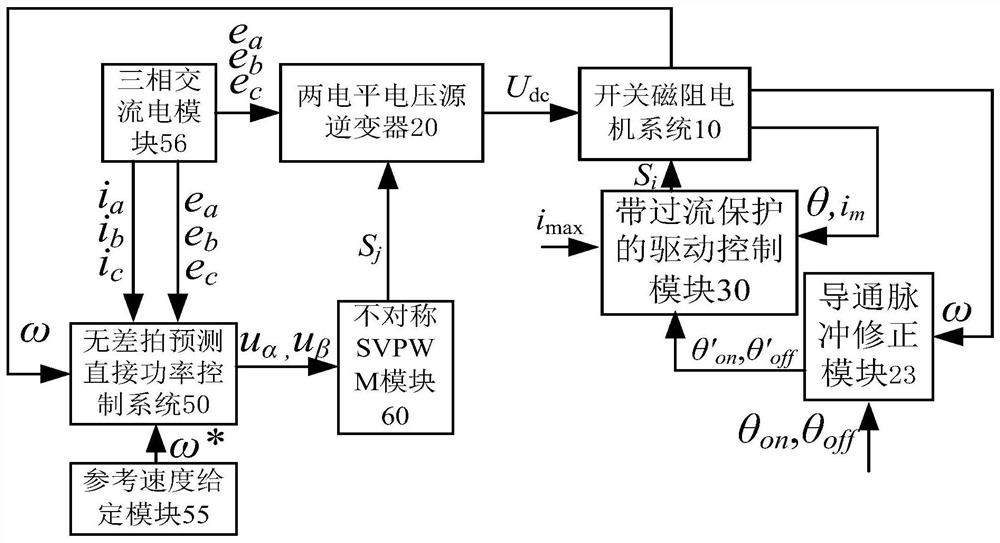

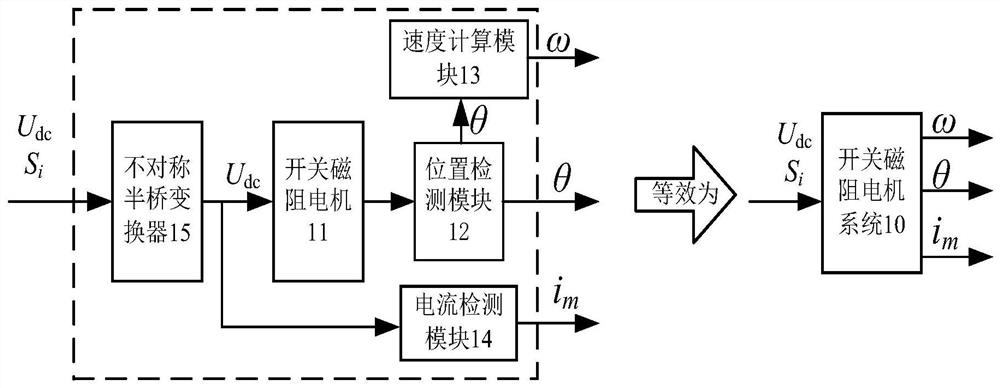

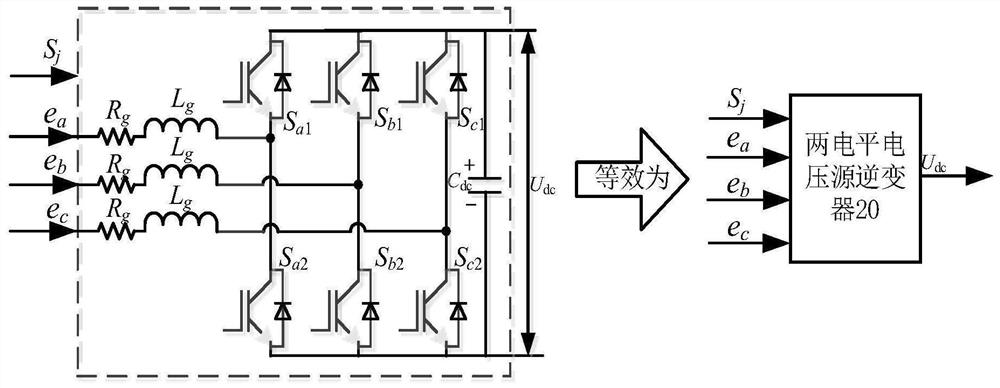

[0020] like figure 1 shown and figure 2 As shown, the present invention consists of a three-phase alternating current module 56, a two-level voltage source inverter 20, an on-pulse correction module 23, a drive control module 30 with overcurrent protection, a deadbeat predictive direct power control system 50, reference The speed setting module 55 and the asymmetric SVPWM module 60 are composed, and are connected to the switched reluctance motor system 10 including the switched reluctance motor 11 to control the switched reluctance motor 11 in the switched reluctance motor system 10 . The three-phase AC power module 56 is connected to an external power supply and outputs a three-phase AC voltage e a ,e b ,e c and current i a ,i b ,i c , the output terminals of the three-phase AC power module 56 are respectively connected to the two-level voltage source inverter 20 and the deadbeat predictive direct power control system 50, and the three-phase AC voltage e a ,e b ,e c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com