Intragranular distribution reinforcement composite material powder and preparation and forming methods thereof

A composite material and reinforcement technology, which is applied in the field of preparing carbon nanotube aluminum matrix composite materials by powder metallurgy method, can solve the problems of complicated ball milling process, etc., and achieve the effects of simple and easy operation, low oxygen content and good strong-plastic matching in the preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

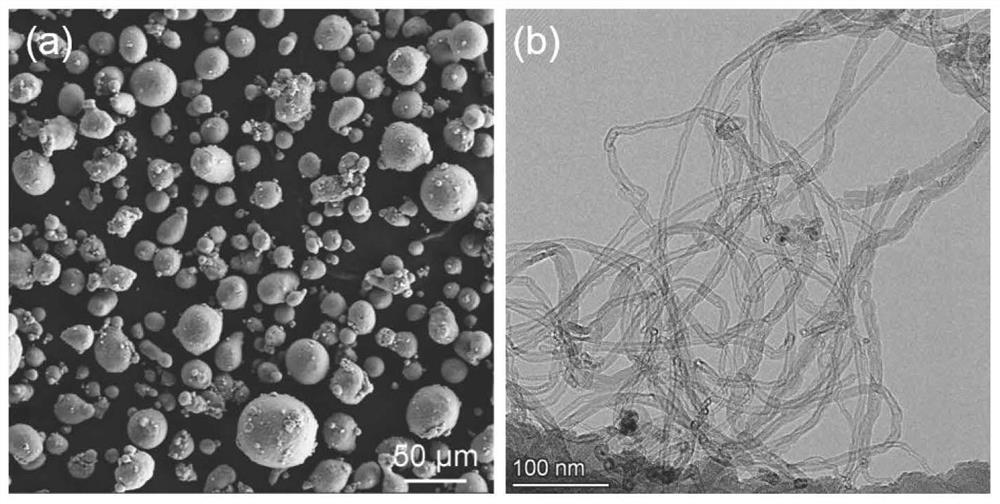

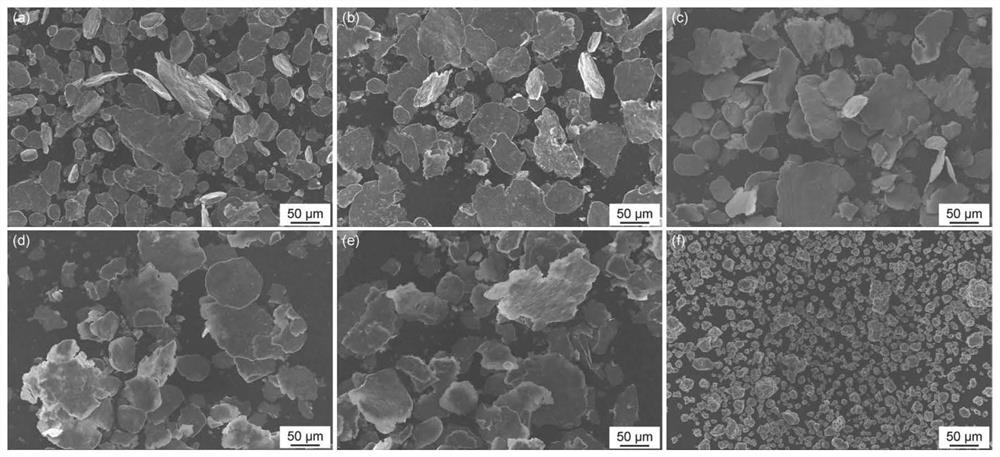

[0078] The preparation method of intragranular dispersed CNTs / Al composite material in this example includes the preparation process and forming process of intragranular dispersed CNTs / Al composite material powder, and at the same time as a comparison group, the CNTs / Al composite material powder with grain boundary distribution is prepared In this example, 1# represents the composite material powder / block in the state of dispersed CNTs in the grain, and 2# represents the composite material powder / block in the state of dispersed CNTs in the grain boundary. The SEM morphology of the powder primary Al powder is as follows figure 1 As shown in (a), TEM morphology of CNTs powder figure 1 as shown in (b),

[0079] The specific intragranular and grain boundary CNTs / Al composite material powder preparation method comprises the following steps:

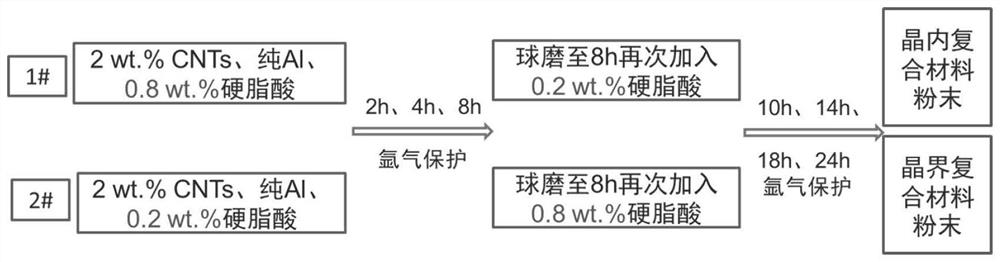

[0080] Step 101, powder proportioning and processing, the specific flow diagram is as follows figure 2 Shown:

[0081] A total of 120 g ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Microhardness | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com