Application of chitosan/cellulose composite microsphere immobilized copper in preparation of diphenyl silane compound

A technology of diphenylsilane and composite microspheres, which is applied in the fields of compounds of group 4/14 elements of the periodic table, silicon organic compounds, metal/metal oxide/metal hydroxide catalysts, etc., which can solve the problem that catalysts cannot be recycled , high cost, incapable of industrialization and other problems, to achieve good biocompatibility, long service life and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The active component of the CC@Cu catalytic material provided by the embodiment of the present invention is copper, and the carrier is chitosan / cellulose composite microspheres; meanwhile, the relative content of the active component copper in the CC@Cu catalytic material is 1.75 mmol / g.

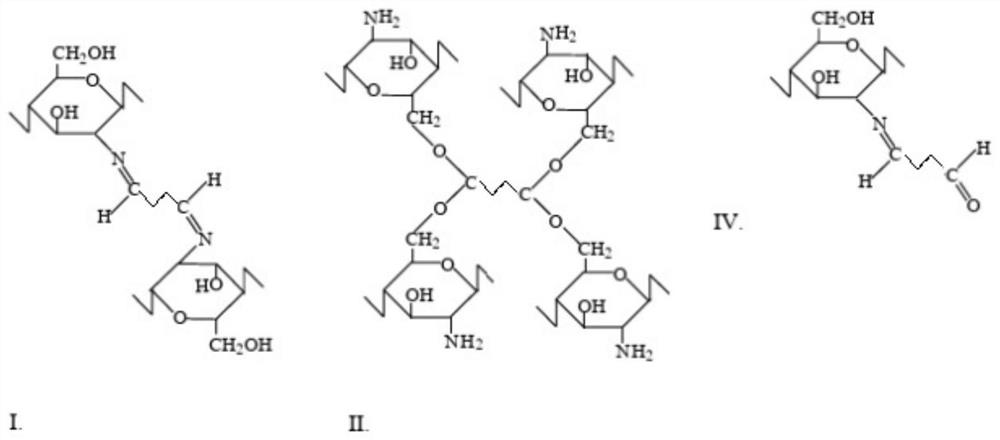

[0042] Among them, the carrier is chitosan / cellulose composite microspheres, and the chitosan / cellulose composite microspheres are cellulose mixed with chitosan in an acidic mixed solution, then added to an alkaline solution to suspend to form microspheres, and succinic dialdehyde is added to form microspheres. Combined composite microspheres. Subsequently, copper ions were adsorbed to form chitosan / cellulose composite microsphere-immobilized copper catalytic material (CC@Cu).

[0043] The embodiment of the present invention also provides a preparation method of CC@Cu catalytic material, which includes three major steps:

[0044] 1) Preparation of chitosan / cellulose microspheres: Add...

Embodiment 2~4

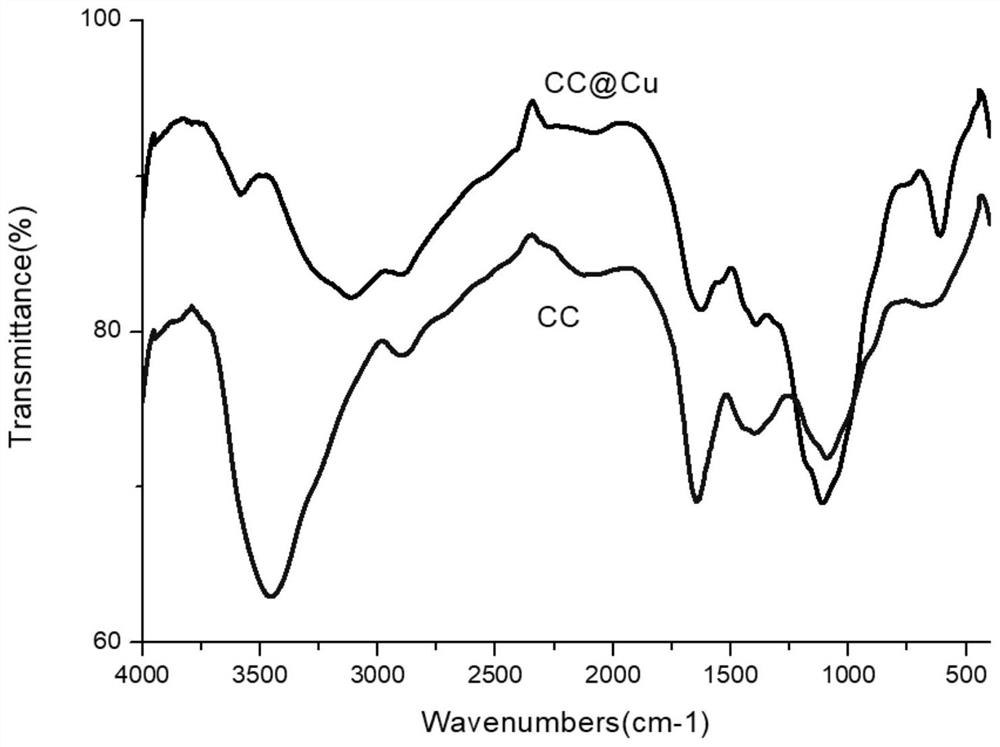

[0050] The CC@Cu catalytic material is prepared by the method of Example 1, the difference is that in the second) step of Example 2, the chitosan unit body: succinic dialdehyde=1mol:1mol, this time may be due to incomplete crosslinking, microspheres Be transparent, fragility and variability, promptly get rid of this ratio; In the 2nd) step of embodiment 3, chitosan unit body: succinic dialdehyde=1mol:2mol, possibly cross-linking is incomplete, and microsphere is transparent, easily Denaturation; in the 2nd) step of embodiment 4, chitosan unit body: succinic dialdehyde=1mol:6mol, microsphere is partial brown solid shape, stable form. combine figure 2 And embodiment 1 to the infrared spectroscopic analysis of catalytic material, when the-C=O of succinaldehyde and the-NH of chitosan unit body 2 When it is 2:1 or 4:1, the crosslinking is not complete, and all the ketone groups attributable to succinic dialdehyde participate in the Schiff base reaction and acetalization reaction,...

Embodiment 5

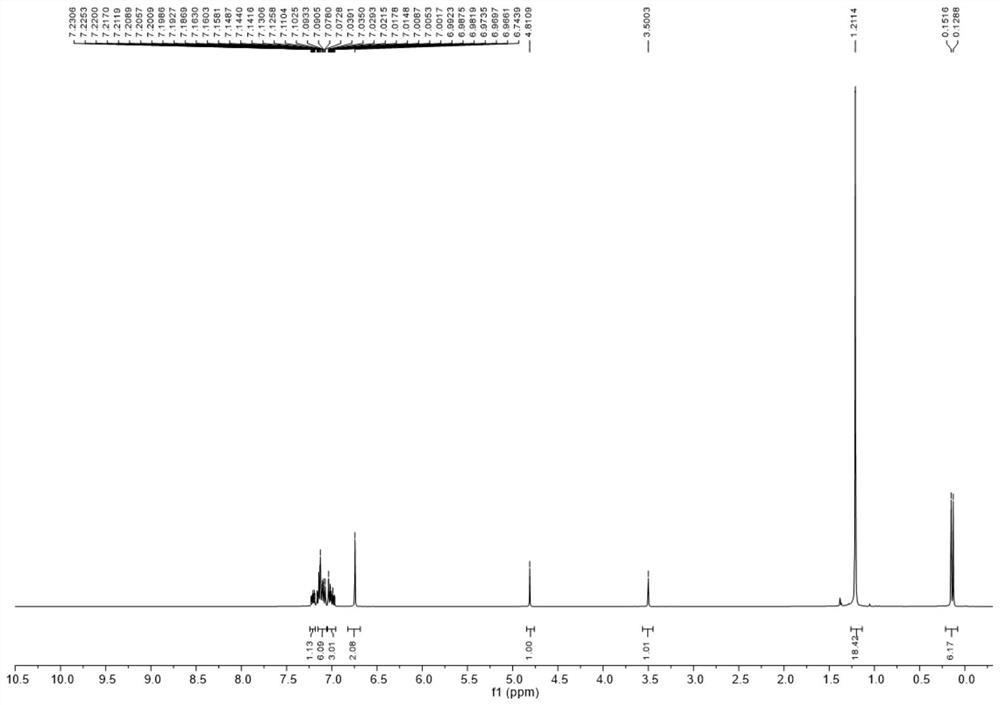

[0052] The embodiment of the present invention also provides a method of applying CC@Cu catalytic material to the silicon addition reaction between p-benzoquinone methyl compound I and diboronic acid pinacol dimethyl silicon reagent, the specific steps are as follows: p-benzoquinone Methyl compound, diboronic acid pinacol dimethyl silicon reagent and CC@Cu catalytic material (prepared in Example 1) were added to the mixed solvent of 5ml water according to the molar ratio of 1:1.2:0.01, and the CC@Cu catalytic material The ratio of the amount to water is 0.002mmol: 2ml, and stirred at room temperature for 12h; after filtering the CC@Cu catalytic material, extracting and spinning the solvent, and separating by thin layer chromatography, the p-benzoquinone methyl compound and bis-benzoquinone methyl compound are obtained. The product of the silicon addition reaction between boric acid pinacol dimethyl silicon reagents is diphenylsilane compound II. At the same time, the CC@Cu cat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com