Preparation method of high-purity polyethylene glycol diacrylamide

A technology of polyethylene glycol bisacrylamide and polyethylene glycol, applied in the field of preparation of high-purity polyethylene glycol bisacrylamide, can solve problems such as complicated operation, achieve high purity, accelerate reaction and improve yield. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

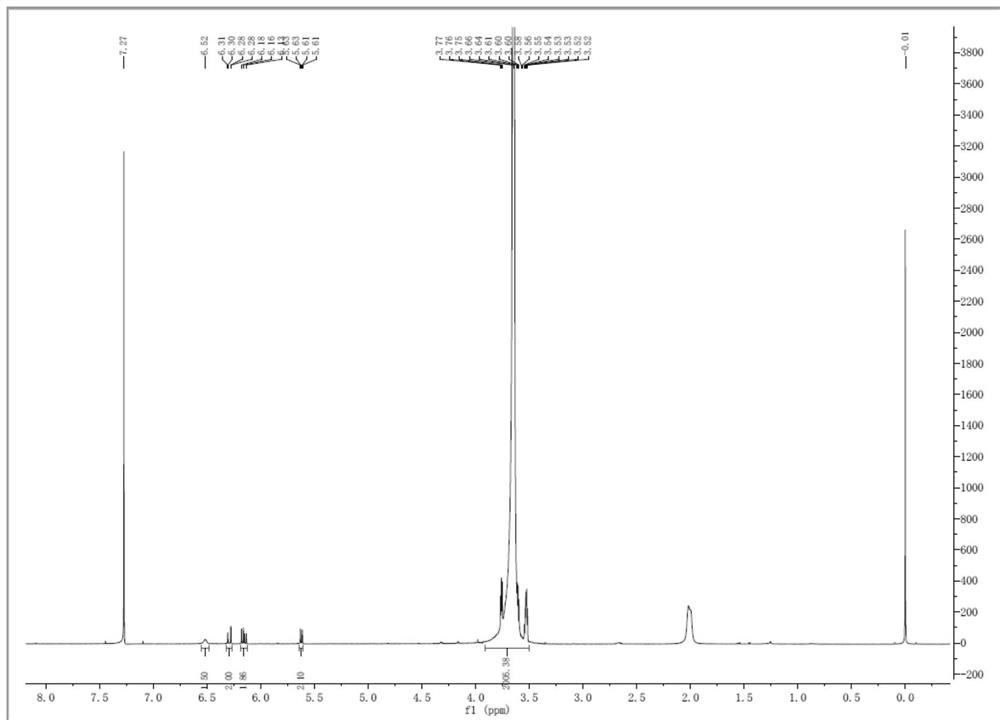

Image

Examples

Embodiment 1

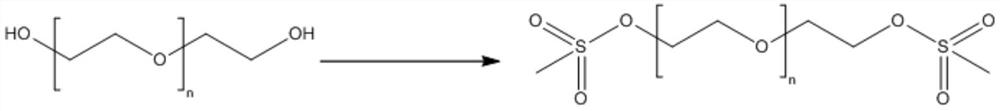

[0019] Preparation of ethylene glycol mesylate

[0020]

[0021] Weigh 50g of PEG8000 into a 250ml three-neck flask, add 140ml of ethyl acetate, cool to 0-10°C in an ice-water bath with stirring, add 2.15ml of TEA, add 36mg of DMAP, stir for 10-30min, add 2.35ml of methanesulfonyl chloride, and naturally heat up to 25-35°C, stirred for 16-20h. Suction filter the reaction solution to remove insoluble impurities, add 300 ml of saturated saline, stir and wash, separate the liquids to obtain the DCM phase, dry and filter over anhydrous sodium sulfate, concentrate the filtrate under reduced pressure to a viscous state, pour 130 ml of tertiary methyl ether to precipitate, The solid was obtained by suction filtration, and dried in a vacuum oven at 35-50° C. to obtain 45 g of a white solid (ie, ethylene glycol mesylate).

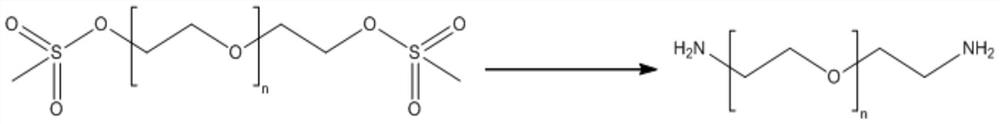

[0022] Preparation of aminopolyethylene glycol

[0023]

[0024] Weigh 44.0g of the reactant obtained in the previous step into a 500ml three-necked fla...

Embodiment 2

[0029] The difference from Example 1 is that Preparation of aminopolyethylene glycol

[0030] Weigh 44.0g of the reaction product obtained in the previous step into a 500ml three-neck flask, add 400ml of ammonia water, add 1.4g of ammonium chloride and stir at room temperature for 1-2 days, add 400ml of DCM to the reaction solution, separate and collect the DCM phase, anhydrous sulfuric acid Sodium-dried and filtered with suction, the filtrate was concentrated under reduced pressure to thick, and 50ml of tertiary methyl ether was added to precipitate it. The solid was obtained by suction filtration, and dried in a vacuum oven at 35-50° C. to obtain 32 g of a white solid with a yield of 72.7% and a purity of 98.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com