Method for preparing nano-crystalline cellulose by ionic liquid-sulfuric acid system and regulating and controlling morphology of nano-crystalline cellulose

The technology of nanocellulose and ionic liquid is applied in the field of preparation of nanocellulose and its shape regulation, which can solve the problems of equipment corrosion, complicated reaction steps and high acid concentration, so as to improve the yield, improve the reaction accessibility, The effect of reducing acid concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

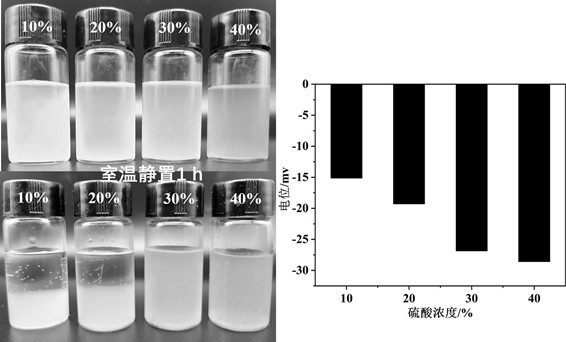

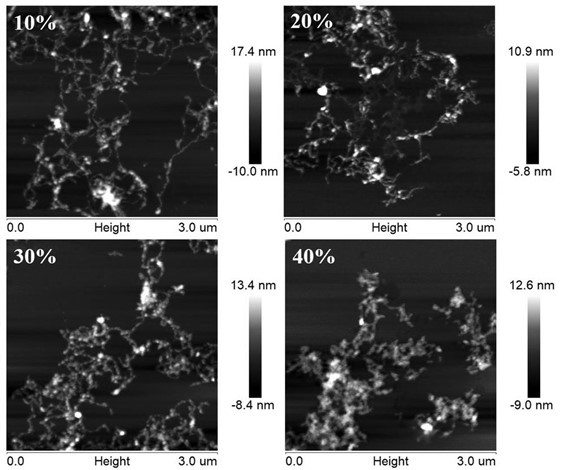

[0024] Mix microcrystalline cellulose and ionic liquid 1-butyl-3-methylimidazolium chloride (BMIMCl) at a ratio of 1:30 (w / w), then stir and heat in an oil bath at 90 °C for 2 h to make It swells and partially dissolves. Continue to add sulfuric acid solution (10%) at a ratio of 1:1 (w / w) to the ionic liquid for mixing, sonicate (300 W, 30 min), then continue heating and hydrolysis (90°C, 3 h), add 3 times the volume The reaction was terminated with distilled water, and then centrifuged and washed with distilled water for 3 times (5000 rpm, 5 min) to collect the samples, dialyzed in distilled water until the dialysate was neutral, and the nanocellulose suspension was obtained.

Embodiment 2

[0026] Mix microcrystalline cellulose and ionic liquid 1-butyl-3-methylimidazolium chloride (BMIMCl) at a ratio of 1:30 (w / w), then stir and heat in an oil bath at 90 °C for 2 h to make It swells and partially dissolves. Continue to add sulfuric acid solution (20%) at a ratio of 1:1 (w / w) to the ionic liquid for mixing, sonicate (300 W, 30 min), then continue heating and hydrolysis (90°C, 3 h), add 4 times the volume The reaction was terminated with distilled water, and then centrifuged and washed with distilled water for 3 times (5000 rpm, 5 min) to collect the samples, dialyzed in distilled water until the dialysate was neutral, and the nanocellulose suspension was obtained.

Embodiment 3

[0028] Mix microcrystalline cellulose and ionic liquid 1-butyl-3-methylimidazolium chloride (BMIMCl) at a ratio of 1:30 (w / w), then stir and heat in an oil bath at 90 °C for 2 h to make It swells and partially dissolves. Continue to add sulfuric acid solution (30%) at a ratio of 1:1 (w / w) to the ionic liquid for mixing, sonicate (300 W, 30 min), then continue heating and hydrolysis (90°C, 3 h), add 5 times the volume Distilled water was used to terminate the reaction, and then centrifuged and washed with distilled water for 4 times (6000 rpm, 10 min) to collect the samples, and dialyzed in distilled water until the dialysate was neutral to obtain nanocellulose suspension.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com