Method for improving mechanical property of electrolytic copper foil and additive used by method

A technology of copper foil mechanics and electrolytic copper foil, which is applied in the field of lithium-ion batteries, can solve problems such as reduced tensile properties, weak mechanical properties, and difficult processes, and achieve the effects of enhanced orientation, grain refinement, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] The additive used in this embodiment is: sodium polydisulfide dipropane sulfonate, and the addition amount of the additive is: 0.01mol / L.

[0056] It is prepared by the process of industrial conventional copper foil preparation. The specific process is: control the current density to 5 A / m 2 .

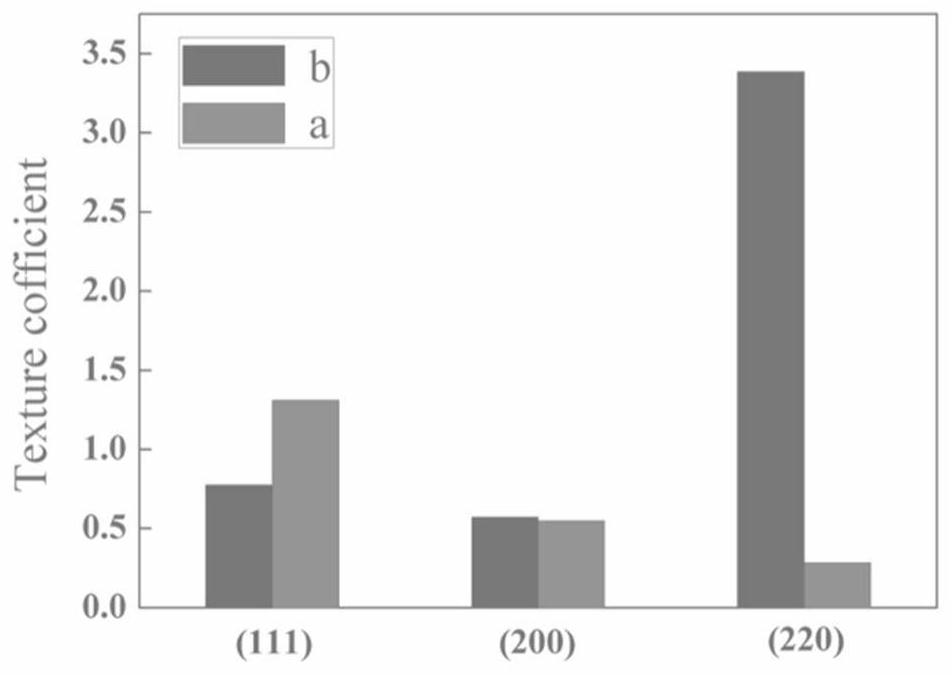

[0057] The prepared electrolytic copper foil was tested according to the national standard GB / T-5230, and the test showed that the tensile strength of the prepared electrolytic copper foil was 476.6 MPa. In addition, Cu(111), Cu(200) and Cu(220) crystal plane texture coefficients were calculated, and the results are as follows figure 1 shown. In the figure: a is the smooth surface of the electrolytic copper foil (right column), b is the rough surface of the electrolytic copper foil (left column).

Embodiment 2

[0063] The specific operation is the same as in Example 1, except that the additive is polyethylene glycol.

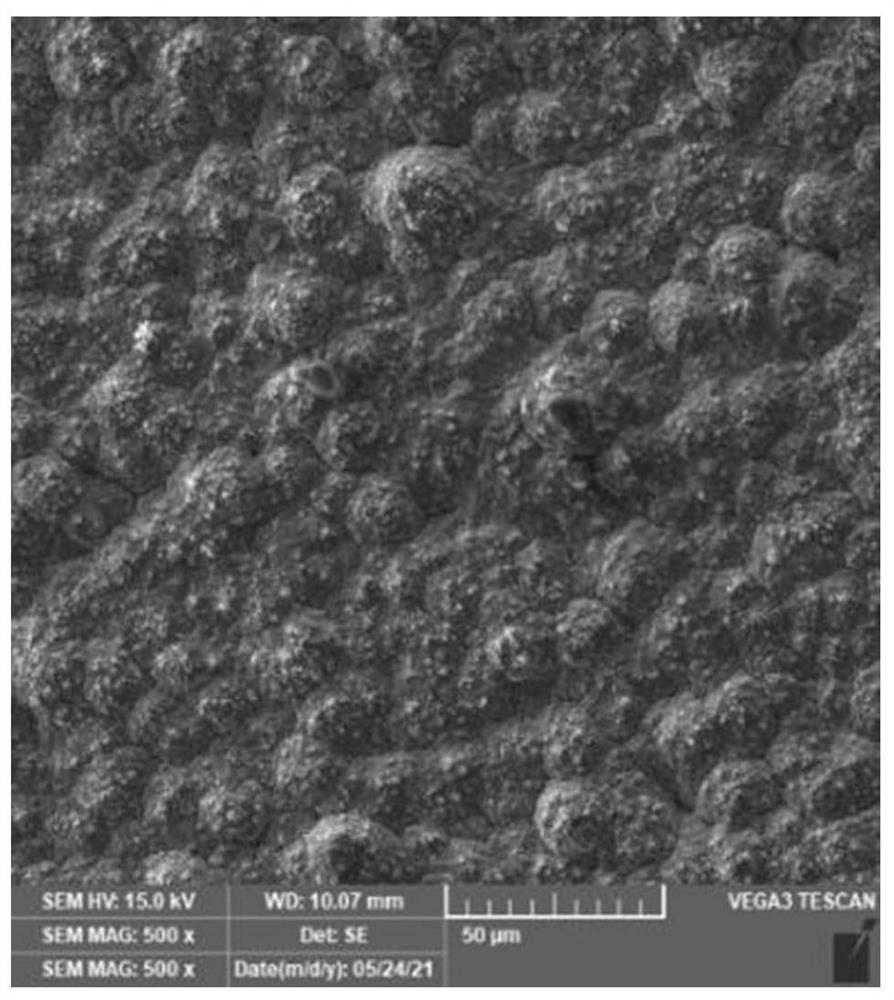

[0064] The prepared electrolytic copper foil was tested according to the national standard GB / T-5230, and the test showed that the tensile strength of the prepared electrolytic copper foil was 451.45 MPa. The SEM characterization picture of the matte surface of the obtained electrolytic copper foil is as follows Figure 5 shown.

[0065] From Figure 5 It can be clearly seen that after the addition of alcohol additives, the surface of the electrolytic copper foil has a very obvious grain refinement, and as Figure 4 Disorderly bumps in the center are significantly reduced.

Embodiment 3

[0067] The specific operation is the same as in Example 1, except that the additives are 0.05 mol / L ether and 0.05 mol / L polyethyleneimine.

[0068] The prepared electrolytic copper foil was tested according to the national standard GB / T-5230, and the test showed that the tensile strength of the prepared electrolytic copper foil was 511.61 MPa. The SEM characterization picture of the matte surface of the obtained electrolytic copper foil is as follows Figure 6 shown.

[0069] From Figure 6 It can be clearly seen that after the addition of ether and amine additives, the copper foil grains obviously changed the growth direction, and produced a significant refinement, changed the texture characteristics of the copper foil, and significantly improved the copper foil texture. mechanical properties.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com