Anti-scaling device and method for enhancing heat exchange

A technology to enhance heat exchange and heat medium, applied in chemical instruments and methods, damage protection, water softening, etc., to achieve the effects of ensuring evaporation, reducing scaling, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

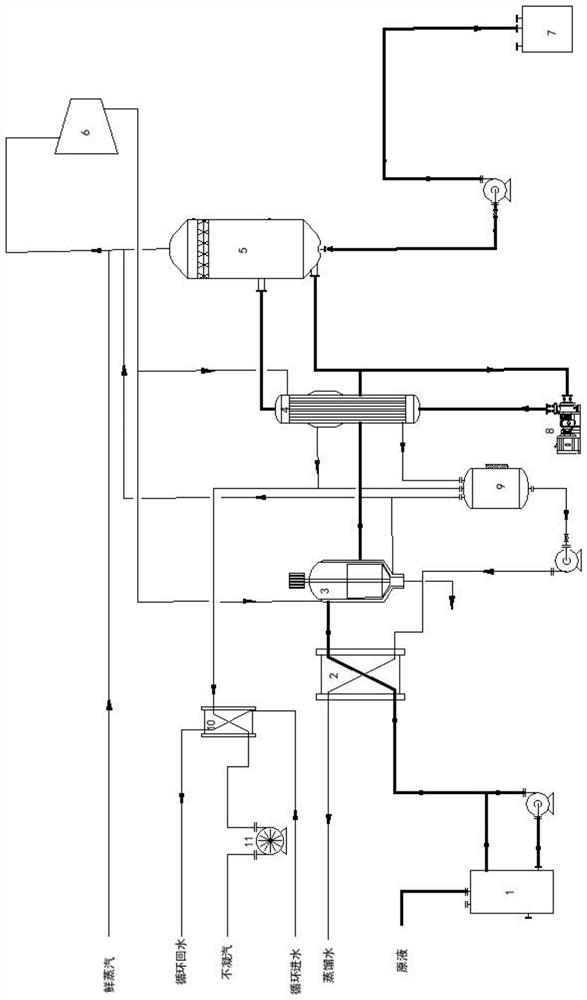

[0020] figure 1 As shown, this embodiment proposes an anti-fouling device for enhanced heat exchange, including an evaporation branch, which includes a liquid storage tank 1, a preheater 2, a scale introduction device 3, an evaporator 4 and a separation tank connected in sequence. Tank 5; the bottom of the separation tank 5 is connected to the discharge liquid storage tank 7 through a pipeline, and the bottom of the separation tank 5 is connected to the evaporator 4 through a pipeline and a forced circulation pump 8 in sequence.

[0021] In this embodiment, a scale introduction device 3 is added before the evaporator 4, and the calcium carbonate scale in the waste water is concentrated inside the scale introduction device 3, so as to prevent the salt scale from accumulating on the evaporator 4 during the evaporation process and reduce the evaporator 4 scale. The amount of fouling can ensure the evaporation effect of the evaporator 4, so that the system can run continuously. F...

Embodiment 2

[0033] An anti-scaling method that strengthens heat exchange. After the wastewater passes through the preheater 2, the wastewater is heated to 60-70°C. It is adjusted to 9-12, the amount of sodium carbonate added is 5-30 mg / L, and then the waste water is introduced into the evaporator 4 for evaporation, and finally enters the separation tank 5 through the pipeline. If the evaporation concentrate in the separation tank 5 meets the preset concentration requirements, The evaporated concentrated liquid flows out from the bottom of the separation tank 5. If the evaporated concentrated liquid does not meet the preset concentration requirements, the evaporated concentrated liquid is returned to the evaporator 4 through the forced circulation pump 8 for heating and evaporation.

[0034] The water vapor evaporated from the wastewater flows from the upper part of the separation tank 5 through the compressor 6, and after being recompressed by the compressor 6, it becomes a high-temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com