Cuttage type insulating glue pressing process based on copper substrate

A technology of insulating glue and copper substrate, which is applied in the direction of circuit lamination, circuit thermal components, electrical components, etc., can solve the problems of reduced thermal conductivity, uneven pressure, and defects, and achieve the effect of improving bonding strength and improving thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

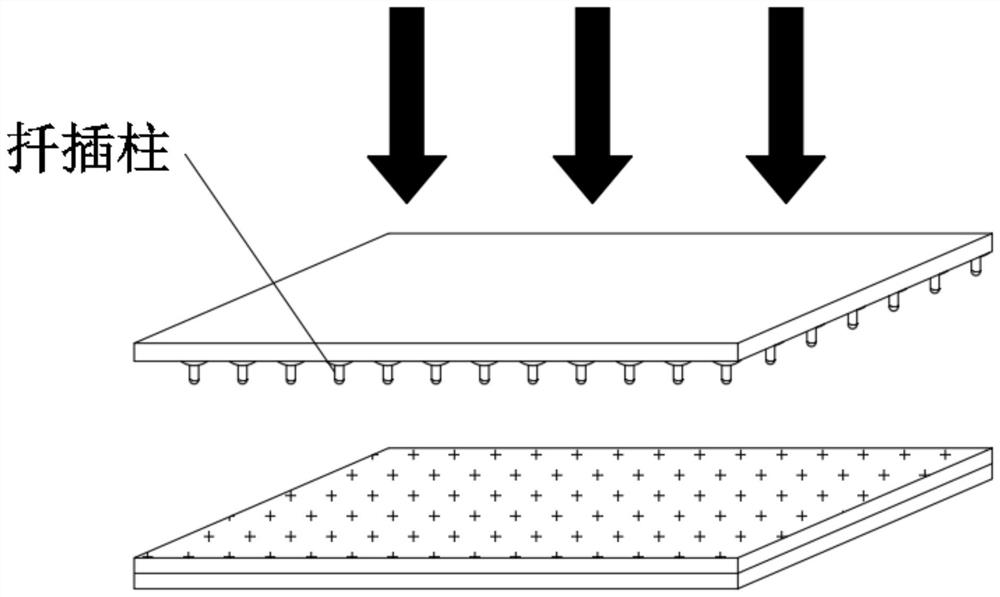

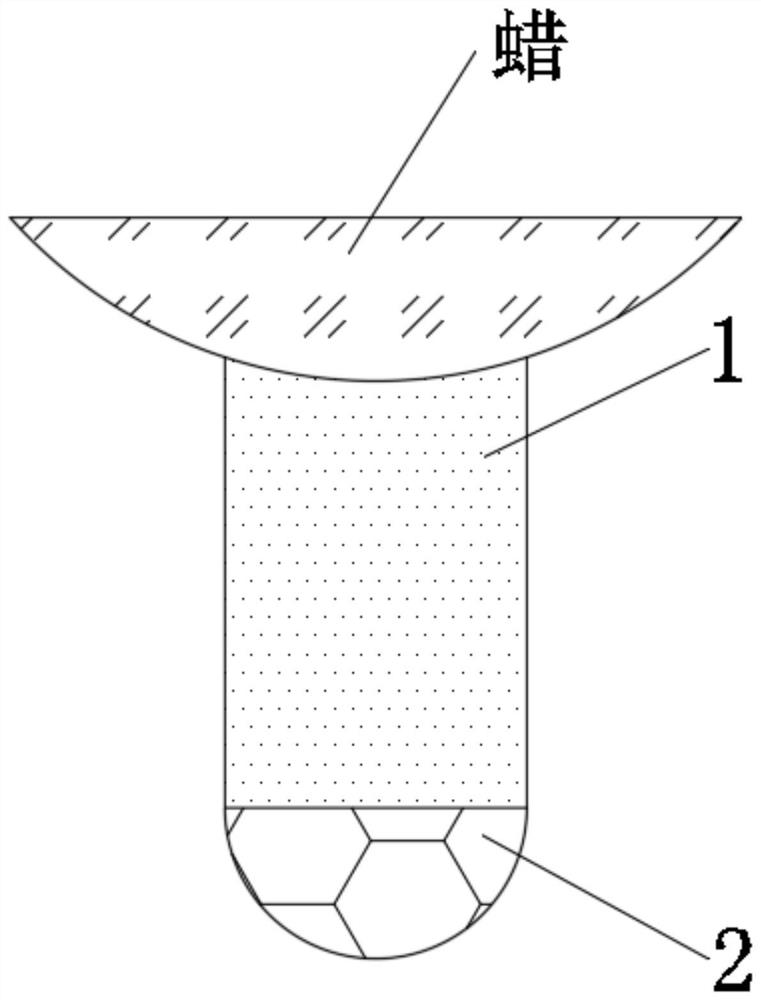

[0044] see figure 1 , a cutting-type insulating glue lamination process based on a copper substrate, comprising the following steps:

[0045] S1. Take a plurality of cutting posts and immerse one end into the wax liquid, and then quickly transfer it to the back of the copper foil for uniform adsorption, and form a temporary connection after the wax liquid is cooled and solidified;

[0046] S2. Take insulating glue and apply it to the surface of the metal base to ensure uniform thickness, and then align the copper foil connected with the cutting posts to the metal base for pressing;

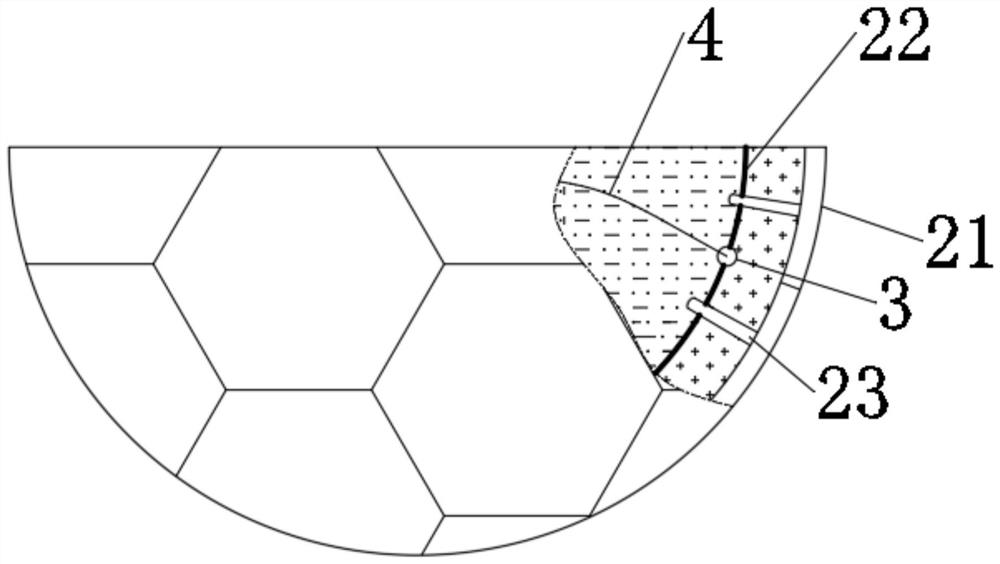

[0047] S3. Heat the metal base to 150-200°C, and apply a magnetic field under the metal base to trigger the expansion and exhaust action of the cutting column, eliminate air bubbles in the insulating glue, and ensure that the insulating glue is evenly stressed;

[0048] S4. Heating for 3-5h until the insulating adhesive is fully cured, and then let it stand for natural cooling;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com