Stain-removing whitening toothpaste and preparation method thereof

A toothpaste and whitening technology, applied in the field of stain removal and whitening toothpaste and its preparation, can solve the problems of weakened friction, hard texture of friction agent, poor use feeling, etc., and achieve the effect of improving use feeling and good antibacterial and bacteriostatic effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

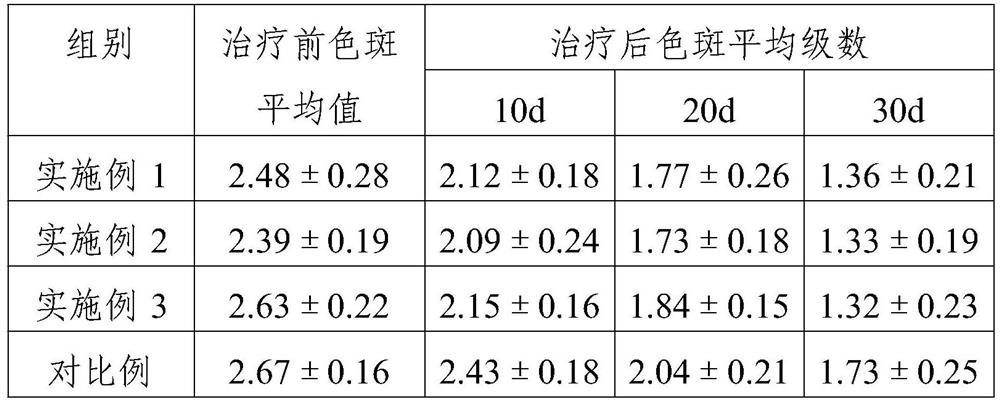

Examples

Embodiment 1

[0025] A stain-removing and whitening toothpaste, wherein the stain-removing and whitening toothpaste is made of the following raw materials in parts by weight: 18 parts of calcium pectin microspheres, 25 parts of humectants, 6 parts of nano-silica, 0.6 parts of xanthan gum, lauryl alcohol 1.2 parts of sodium polyether sulfate, 1 part of sorbic acid, 1 part of xylitol, 0.1 part of vitamin E, 0.2 parts of peppermint oil, 0.2 parts of bisoxyphenylbiguanidine hexane, and 10 parts of water.

[0026] Wherein, the moisturizing agent is a mixture of glycerin, sorbitol and polyethylene glycol in a mass ratio of 10:2:3; the particle size of the calcium pectin microspheres is 10-30 μm.

[0027] The preparation method of described stain removal and whitening toothpaste comprises the following steps:

[0028] (1) Preparation of pectin calcium: choose pectin and calcium hydroxide solution with a calcium ion concentration of 0.02mol / L according to the mass ratio of 1:3, heat and mix at 45°C...

Embodiment 2

[0033] A stain-removing and whitening toothpaste, wherein the stain-removing and whitening toothpaste is made of the following raw materials in parts by weight: 20 parts of calcium pectin microspheres, 30 parts of humectants, 8 parts of nano-silica, 0.7 parts of xanthan gum, lauryl alcohol 1.6 parts of sodium polyether sulfate, 2 parts of sorbic acid, 3 parts of xylitol, 0.2 parts of vitamin E, 0.3 parts of peppermint oil, 0.3 parts of bis-oxyphenylbiguanidine hexane, 50 parts of water.

[0034] Wherein, the moisturizing agent is a mixture of glycerin, sorbitol and polyethylene glycol in a mass ratio of 12:3:4; the particle size of the calcium pectin microspheres is 10-30 μm.

[0035] The preparation method of described stain removal and whitening toothpaste comprises the following steps:

[0036] (1) Preparation of pectin calcium: choose pectin and calcium hydroxide solution with a calcium ion concentration of 0.02mol / L according to the mass ratio of 1:4, heat and mix at 50°C...

Embodiment 3

[0041] A stain-removing and whitening toothpaste, wherein the stain-removing and whitening toothpaste is made of the following raw materials in parts by weight: 19 parts of calcium pectin microspheres, 28 parts of humectants, 7 parts of nano-silica, 0.65 parts of xanthan gum, lauryl alcohol 1.4 parts of sodium polyether sulfate, 1.5 parts of sorbic acid, 2 parts of xylitol, 0.15 parts of vitamin E, 0.25 parts of peppermint oil, 0.25 parts of bis-oxyphenyl diguanidine hexane, 30 parts of water.

[0042] Wherein, the moisturizing agent is a mixture of glycerin, sorbitol and polyethylene glycol in a mass ratio of 11:2.5:3.5; the particle size of the calcium pectin microspheres is 10-30 μm.

[0043] The preparation method of described stain removal and whitening toothpaste comprises the following steps:

[0044] (1) Preparation of pectin calcium: choose pectin and calcium hydroxide solution with calcium ion concentration of 0.02mol / L according to the mass ratio of 1: 3.5, insulate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com