A kind of heavy oil modified nickel-based catalyst and its preparation method and application

A nickel-based catalyst and catalyst technology, applied in the field of oilfield chemistry, can solve problems such as high cost and difficult implementation, and achieve the effects of convenient operation, short time, increased catalytic activity and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

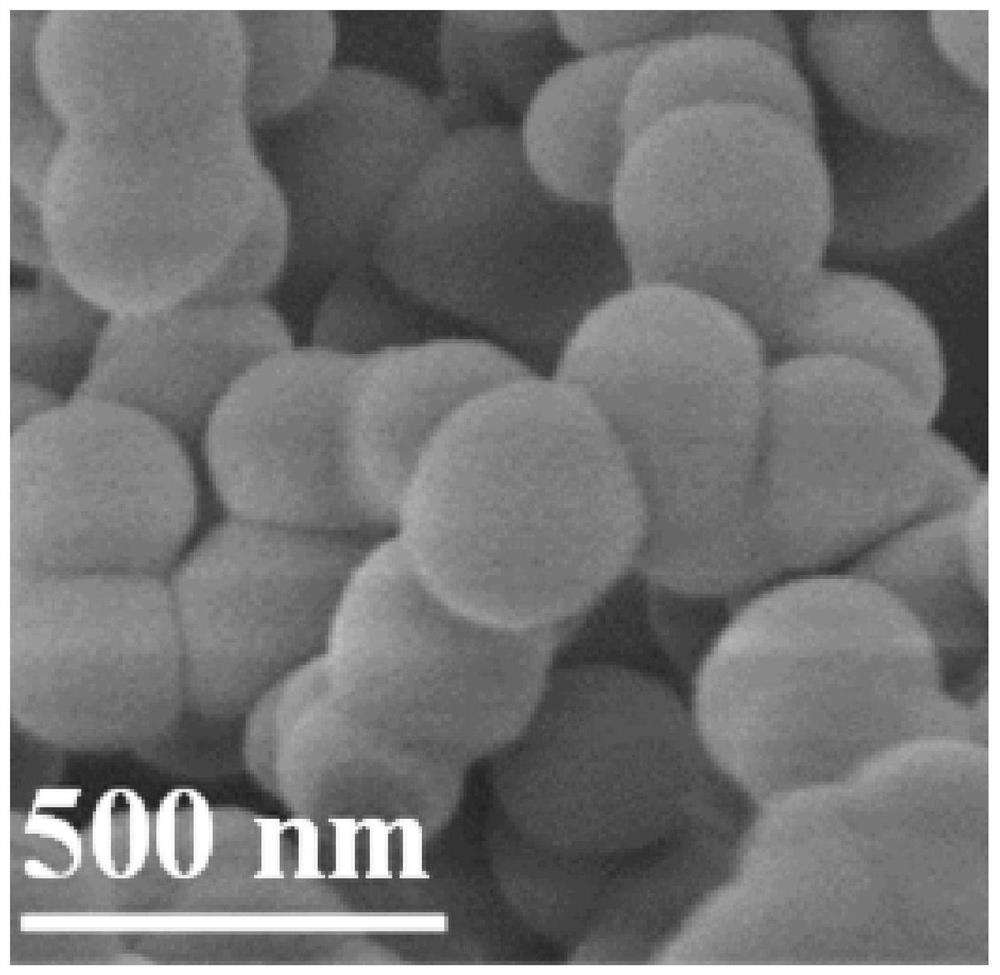

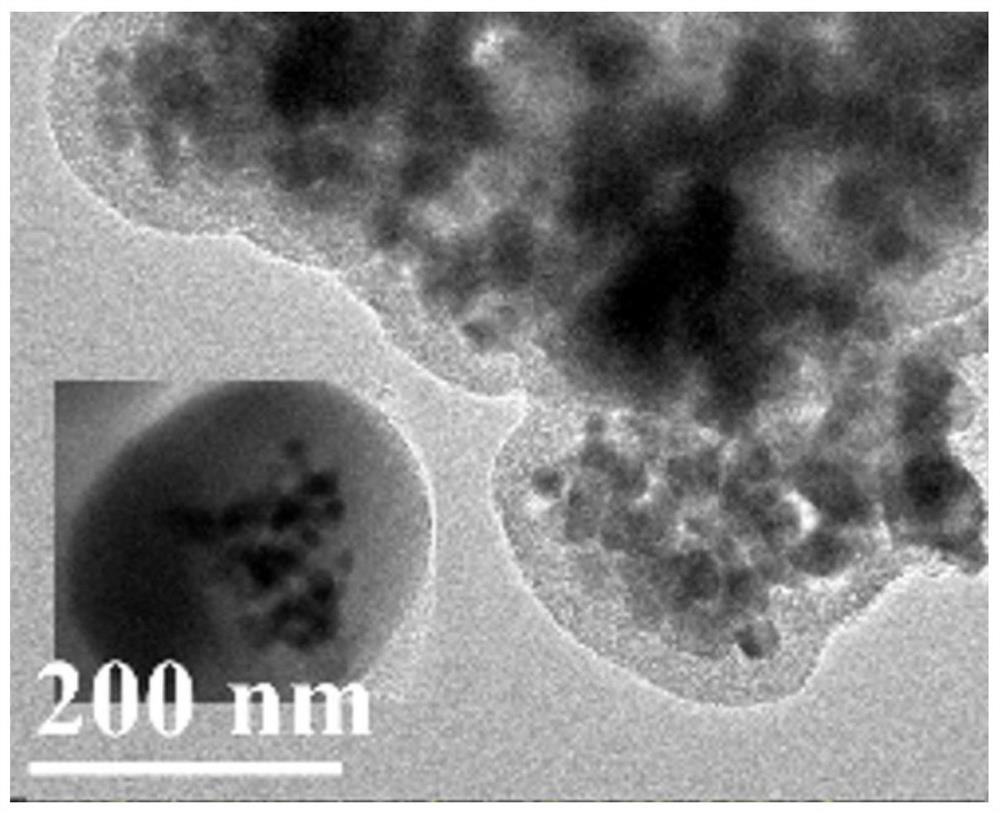

Image

Examples

Embodiment 1

[0116] (1) Preparation of Zr 0.9 Ce 0.1 o2 Carrier: ZrOCl 2 ·8H 2 O and Ce(NO 3 ) 3 ·6H 2 Weigh 10 g of O according to the Zr / Ce molar ratio of 9:1 and dissolve it in 150 mL of EtOH; slowly add NH to the mixture at 30 °C 4 OH, stirred at 300rpm until the pH of the solution reached 9, then continued to stir for 4h; filtered and collected the solid precipitate; washed the solid with EtOH, and dried in an oven at 100°C for 12h; dried the solid at 550°C Calcined for 5 hours, then ground into small particles.

[0117] (2) Preparation of NiPt / Zr 0.9 Ce 0.1 o 2 Catalyst: Add nickel nitrate hexahydrate, chloroplatinic acid and hydrazine hydrate reducing agent in deionized water respectively, and prepare 0.04M nickel nitrate, 0.004M chloroplatinic acid and 0.3M reducing agent solution; / v cyclohexane, 13% v / v Triton X-100 surfactant and 47% v / v isopropanol co-surfactant oil phase mixed system are mixed in equal volume; then the three mixtures obtained are mixed at 500rpm Sti...

Embodiment 2

[0120] (1) Preparation of Zr 0.8 Ce 0.2 o 2 Carrier: ZrOCl 2 ·8H 2 O and Ce(NO 3 ) 3 ·6H 2 Weigh 10 g of O according to the Zr / Ce molar ratio of 8:1, dissolve in 200 mL of EtOH; slowly add NH to the mixture at 25 °C 4 OH, stirred at 400rpm until the pH of the solution reached 9, then continued to stir for 4h; filtered and collected the solid precipitate; washed the solid with EtOH, and dried in an oven at 100°C for 12h; dried the solid at 500°C Calcined for 6 hours, then ground into small particles.

[0121] (2) Preparation of NiPt / Zr 0.8 Ce 0.2 o 2 Catalyst: Add nickel nitrate hexahydrate, chloroplatinic acid and hydrazine hydrate reducing agent in deionized water respectively, and prepare 0.03M nickel nitrate, 0.003M chloroplatinic acid and 0.2M reducing agent solution; / v cyclohexane, 15% v / v Triton X-100 surfactant and 50% v / v isopropanol co-surfactant oil phase mixed system are mixed in equal volume; Stir at a rotating speed of 2h to form three kinds of microe...

Embodiment 3

[0124] (1) Preparation of Zr 0.7 Ce 0.3 o 2 Carrier: ZrOCl 2 ·8H 2 O and Ce(NO 3 ) 3 ·6H 2 Weigh 10 g of O according to the Zr / Ce molar ratio of 7:3, dissolve in 400 mL of EtOH; slowly add NH to the mixture at 20 °C 4 OH, stirred at 350rpm until the pH of the solution reached 8.5, then continued to stir for 5h; filtered and collected the solid precipitate; washed the solid with EtOH, and dried in an oven at 100°C for 12h; dried the solid at 6000°C Calcined for 4 hours, then ground into small particles.

[0125] (2) Preparation of NiPt / Zr 0.7 Ce 0.3 o 2 Catalyst: Add nickel nitrate hexahydrate, chloroplatinic acid and hydrazine hydrate reducing agent in deionized water respectively, and prepare 0.05M nickel nitrate, 0.005M chloroplatinic acid and 0.4M reducing agent solution; / v cyclohexane, 10% v / v Triton X-100 surfactant and 45% v / v isopropanol co-surfactant oil phase mixed system mixed in equal volume; then the three mixtures obtained were mixed at 650rpm Stir at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com