Composite binder as well as preparation method and application thereof

A binder and solvent technology, applied in structural parts, active material electrodes, electrical components, etc., can solve the problems of poor cycle performance of silicon anodes, and achieve the effect of improving ionic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

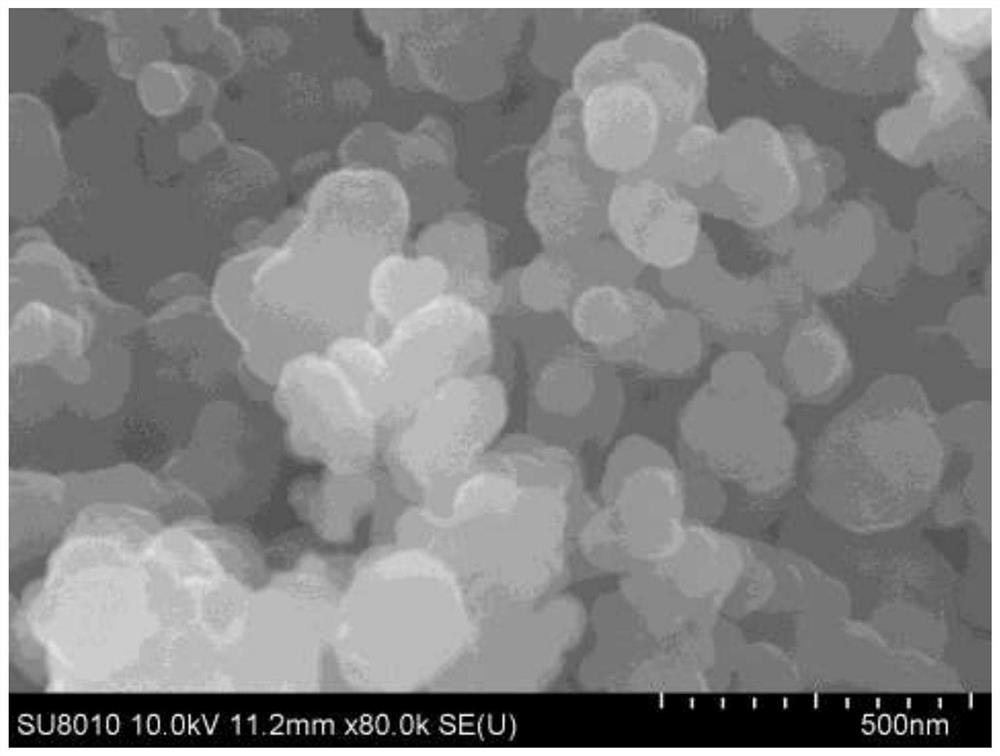

Image

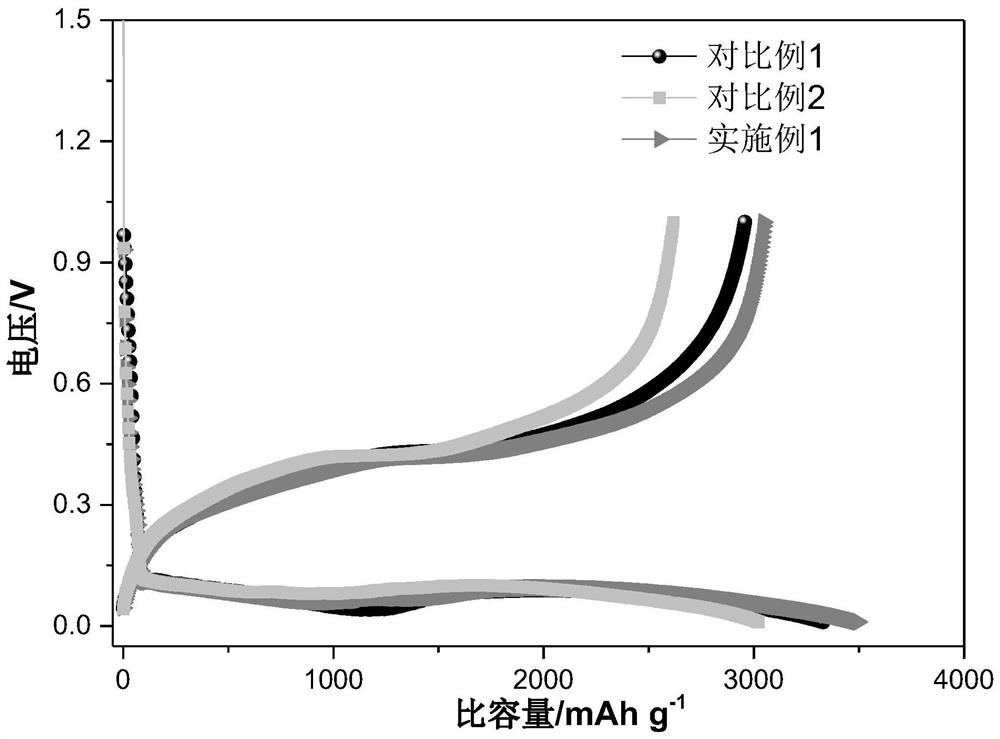

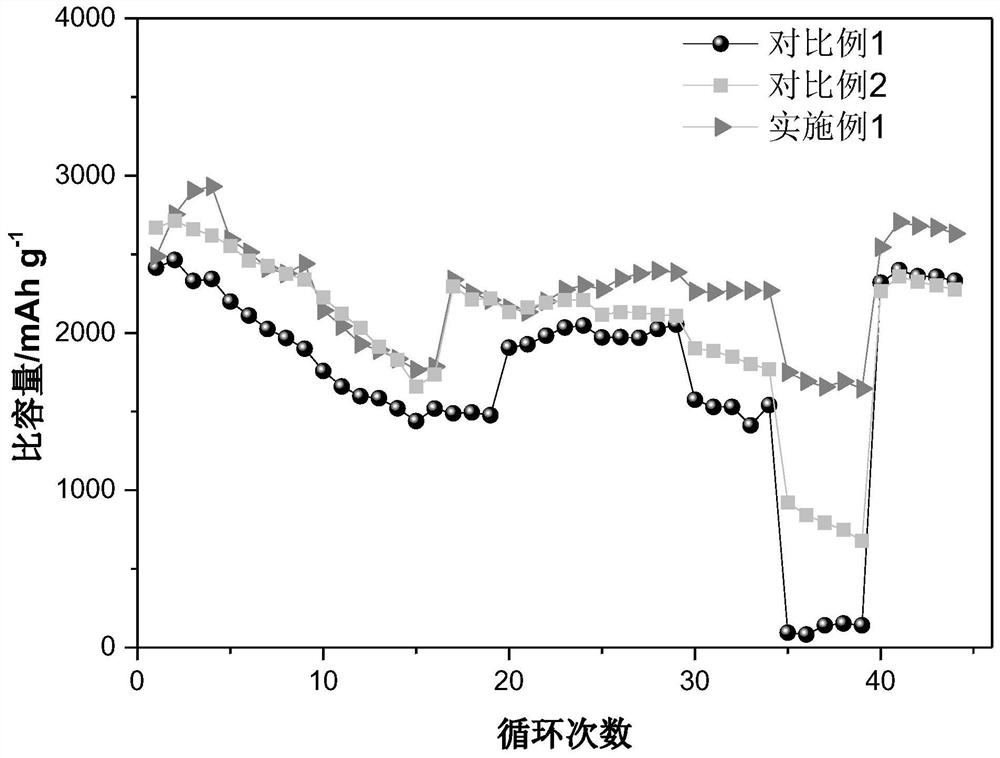

Examples

Embodiment 1

[0029] This embodiment provides a method for preparing a silicon negative electrode of a lithium ion battery using polyvinyl alcohol-zinc trifluorosulfonate as a composite binder, which specifically includes the following steps:

[0030] Step 1: Take 0.3 g of polyvinyl alcohol (with a molecular weight of 130,000-140,000) and dissolve it in deionized water by heating in a high-temperature water bath at 90° C., and stir for 1-2 hours to form a uniform solution.

[0031] Step two, control Zn 2+ The molar ratio of ions to hydroxyl groups in polyvinyl alcohol is 0.03, and the corresponding amount of zinc trifluorosulfonate is slowly added to the polyvinyl alcohol solution, stirred for 1 hour, and a transparent Zn 2+ Aqueous solutions of ionically coordinated polyvinyl alcohol binders.

[0032] Step 3, based on the percentage of polyvinyl alcohol in the composite binder, it is quantitatively introduced into the electrode preparation process to prepare a silicon negative electrode. ...

Embodiment 2

[0035] This embodiment provides a method for preparing a lithium-ion battery silicon negative electrode with polyvinyl alcohol-calcium acrylate as a composite binder. The specific process is the same as in Example (1), except that: Ca 2+ The molar ratio of the number of moles of ions to the hydroxyl groups in polyvinyl alcohol is 0.05:1.

Embodiment 3

[0037] This embodiment provides a method for preparing a polyvinyl alcohol-aluminum trifluoromethane carbonate as a composite binder for a silicon negative electrode of a lithium-ion battery. The specific process is the same as in Example (1), except that: Al 3+ The molar ratio of the number of moles of ions to the hydroxyl groups in polyvinyl alcohol is 0.02:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com