Borate glass ceramic with low dielectric loss, high energy storage density and compact structure, and preparation method and application thereof

A technology of borate glass and glass ceramics, applied in glass manufacturing equipment, glass furnace equipment, glass molding, etc., can solve the problems of complex raw materials, low raw material utilization, and little research on potassium sodium niobate glass ceramic materials, etc. , to achieve the effect of uniform grain size, simplified glass formula and good compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

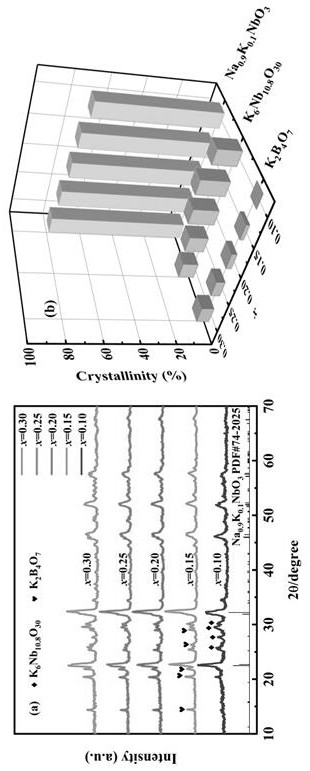

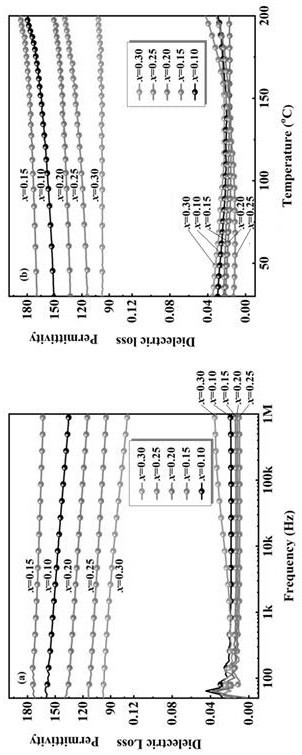

[0032] The crystallization treatment of the glass sample in this embodiment: heat insulation at 800 ° C for 2 h.

[0033] The preparation method of the glass ceramic material of the present embodiment includes the steps of:

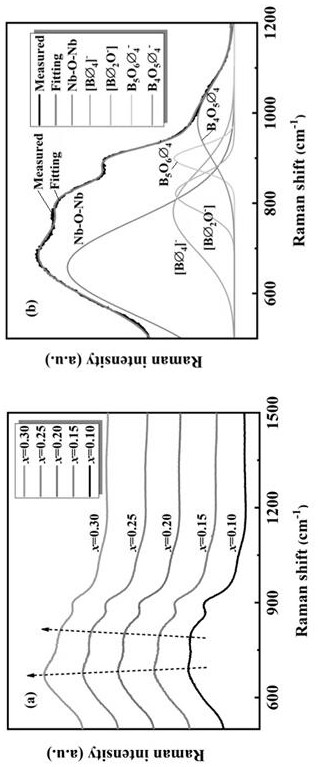

[0034] 1) The glass ceramic material is (1-x): X (x = 0.10), take K by mole percentage (1-x): X (x = 0.10) 2 CO 3 NA 2 CO 3 , NB 2 O 5 , And h 3 BO 3 The mixture is obtained by mixing the ball milling, then drying, and sieved.

[0035] 2) When the quartz crucible is heated from room temperature to 1100 ° C, the mixture is added, then the mixture is added to 1400 ° C, and 50 min is held at 1400 ° C for 50 min to mix uniform mixture, resulting in mixed melt; mixed melt at 500 ° C The preheated copper plate is formed, and the furnace is rapidly placed in a furnace at 500 ° C for 2 h, and the glass substrate after annealing is obtained;

[0036] 3) Insulation at 800 ° C for 2 h and then cool to room temperature with the furnace (K 2 O-NA 2 O-2NB 2 O 5 ) -0.1b 2 O...

Embodiment 2

[0039] In this embodiment, the formulation of the glass sample is (1-x): X (x = 0.15), and the melting is melted and holding 50 min at 1400 ° C, and other conditions are as in Example 1.

Embodiment 3

[0041] The formulation of the glass sample in this embodiment is (1-x): X (x = 0.20), and other conditions are as in Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Energy storage density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com