High-temperature-resistant stone powder adsorption-resistant slump-retaining polycarboxylate superplasticizer and preparation method thereof

A slump-preserving, high-temperature-resistant technology, applied in the field of concrete admixtures, can solve the problems of not being able to meet high-temperature resistance and stone resistance at the same time, poor workability of concrete mixtures, and insufficient initial fluidity of concrete, etc., and achieve good slump. Maintaining properties, improving wrap and wrapping, good workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

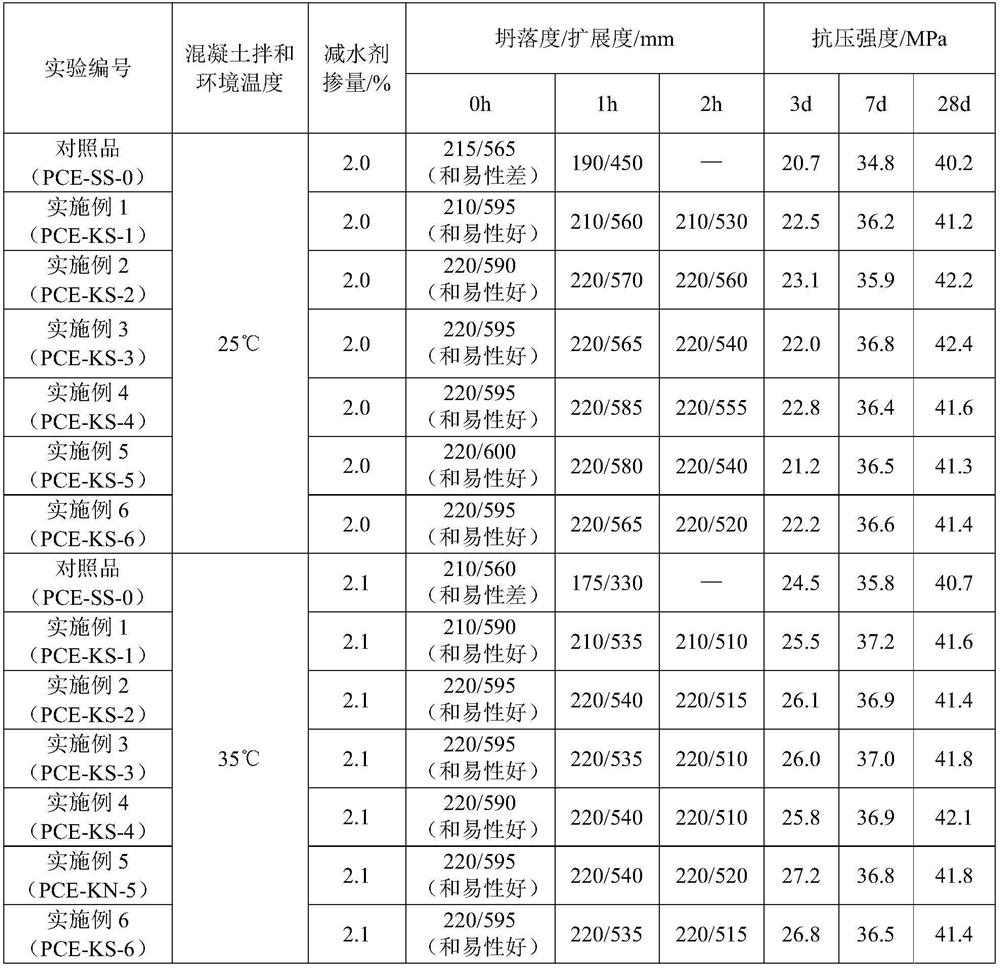

Examples

Embodiment 1

[0041] A high-temperature-resistant stone-powder-resistant adsorption and slump-retaining polycarboxylate water reducer, which consists of the following components in parts by weight: 340 parts of unsaturated polyether macromonomer with a molecular weight of 3000, 22 parts of unsaturated monocarboxylic acid, maleic acid 7.6 parts of iminoalkyl acid, 5.6 parts of unsaturated phosphoric acid ester, 2.4 parts of unsaturated amino acid monoester, 3.6 parts of oxidizing agent, 0.9 part of reducing agent, and 2.5 parts of chain transfer agent.

[0042] The above-mentioned high-temperature-resistant and anti-stone powder adsorption slump-preserving polycarboxylate water-reducer has a preparation method as follows:

[0043] S1: Weigh each raw material component by weight: successively add 340 parts of ethylene glycol monovinyl polyoxyethylene ether, 3.6 parts of 27.5% hydrogen peroxide and deionized water into the reactor, and stir and dissolve evenly, Be prepared as a mixed bottom ma...

Embodiment 2

[0048] A high-temperature-resistant stone-powder-resistant adsorption and slump-retaining polycarboxylate water reducer, comprising the following components in parts by weight: 345 parts of unsaturated polyether macromonomer with a molecular weight of 4000, 26.5 parts of unsaturated monocarboxylic acid, maleic acid 7.2 parts of iminoalkyl acid, 6 parts of unsaturated phosphoric acid ester, 3.6 parts of unsaturated amino acid monoester, 2.8 parts of oxidizing agent, 0.7 part of reducing agent, and 2.65 parts of chain transfer agent.

[0049] The above-mentioned high-temperature-resistant and anti-stone powder adsorption slump-preserving polycarboxylate water-reducer has a preparation method as follows:

[0050] S1: Weigh each raw material component by weight: sequentially add 345 parts of 4-hydroxybutyl vinyl polyoxyethylene ether macromonomer, 2.8 parts of ammonium persulfate and deionized water into the reactor, and stir to dissolve Evenly, it is prepared into a mixed base ma...

Embodiment 3

[0055] A high-temperature-resistant stone-powder-resistant adsorption and slump-retaining polycarboxylate water reducer, comprising the following components in parts by weight: unsaturated polyether macromonomer 330 with a molecular weight of 3000, 25.4 parts of unsaturated monocarboxylic acid, maleic acid 6.6 parts of amino acid, 6.2 parts of unsaturated phosphoric acid ester, 3.6 parts of unsaturated amino acid monoester, 4.2 parts of oxidizing agent, 0.84 part of reducing agent, and 2.4 parts of chain transfer agent.

[0056] The above-mentioned high-temperature-resistant and anti-stone powder adsorption slump-preserving polycarboxylate water-reducer has a preparation method as follows:

[0057] S1: Weigh each raw material component by weight: successively add 330 parts of ethylene glycol monovinyl polyoxyethylene ether, 2.4 parts of 27.5% hydrogen peroxide, 1.8 parts of ammonium persulfate and deionized water into the reactor , and stir and dissolve evenly, and prepare a m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com