Nickel hydroxide nano array/carbon cloth electrode material and preparation method thereof

A nano-array, nickel hydroxide technology, applied in nickel oxide/nickel hydroxide, hybrid/electric double layer capacitor manufacturing, nanotechnology, etc., to achieve the effects of improving utilization, promoting transmission, and good contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

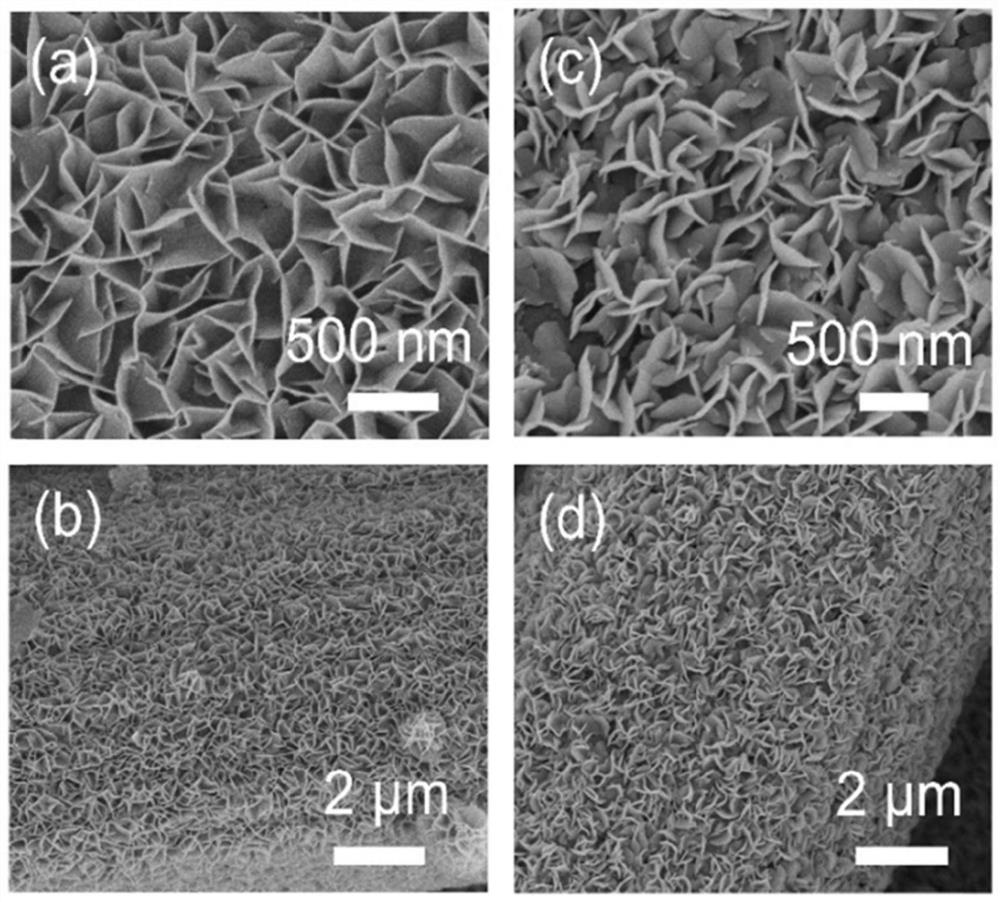

Image

Examples

Embodiment 1

[0027] 1) Clean the commercial (directly purchased) carbon fabric with ethanol, acetone and deionized water, and then dry it into a drying tank.

[0028] 2) The carbon cloth after cleaning is placed in a first solution containing sulfuric acid and nitric acid (volume ratio 1: 1), and then placed in an electrochemical workstation, and activated treatment for 10 minutes under 3V potential.

[0029] 3) Place the carbon cloth after the activation treatment in deionized water for 12 h to remove impurities, and then activate the carbon cloth.

[0030] 4) 0.1g Ni (NO 3 ) 2 · 6h 2 O (nickel of hexahydrate) is dissolved in 10 ml of anhydrous ethanol to form a clear second solution, and the resulting second solution and an activated carbon cloth are placed in a glass culture dish, and the activated carbon bib is immersed in the second solution. .

[0031] 5) Put the petri dish in a 500 ml supercritical reactor with 340 ml of anhydrous ethanol (a substrate under the glass petri dish to ensur...

Embodiment 2

[0034] 1) Clean the commercial carbon fabric with ethanol, acetone and deionized water, and then dried in a drying tank.

[0035] 2) The carbon cloth after cleaning is placed in a first solution containing sulfuric acid and nitric acid (volume ratio 1: 1), and then placed in an electrochemical workstation, and activated treatment for 10 minutes under 3V potential.

[0036] 3) Place the carbon cloth after the activation treatment in deionized water for 12 h to remove impurities, and then activate the carbon cloth.

[0037] 4) Will 0.2g Ni (NO 3 ) 2 · 6h 2 O (nickel of hexahydrate) is dissolved in 10 ml of anhydrous ethanol to form a clear second solution, and the resulting second solution and an activated carbon cloth are placed in a glass culture dish, and the activated carbon bib is immersed in the second solution. .

[0038] 5) Put the petri dish in a 500 ml supercritical reactor with 340 ml of anhydrous ethanol (a substrate under the glass petri dish to ensure that the liquid l...

Embodiment 3

[0041] 1) Clean the commercial carbon fabric with ethanol, acetone and deionized water, and then dried in a drying tank.

[0042] 2) The carbon cloth after cleaning is placed in a first solution containing sulfuric acid and nitric acid (volume ratio 1: 1), and then placed in an electrochemical workstation, and activated treatment for 10 minutes under 3V potential.

[0043] 3) Place the carbon cloth after the activation treatment in deionized water for 12 h to remove impurities, and then activate the carbon cloth.

[0044] 4) 0.3g Ni (NO 3 ) 2 · 6h 2 O (nickel of hexahydrate) is dissolved in 10 ml of anhydrous ethanol to form a clear second solution, and the resulting second solution and an activated carbon cloth are placed in a glass culture dish, and the activated carbon bib is immersed in the second solution. .

[0045] 5) Put the petri dish in a 500 ml supercritical reactor with 340 ml of anhydrous ethanol (a substrate under the glass petri dish to ensure that the liquid level ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com