Organic light emitting diode and preparation method thereof, and display panel

A light-emitting diode and organic technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of low light-emitting efficiency of organic light-emitting diodes, and achieve the effects of maintaining balance, improving capabilities, and quickly and effectively injecting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

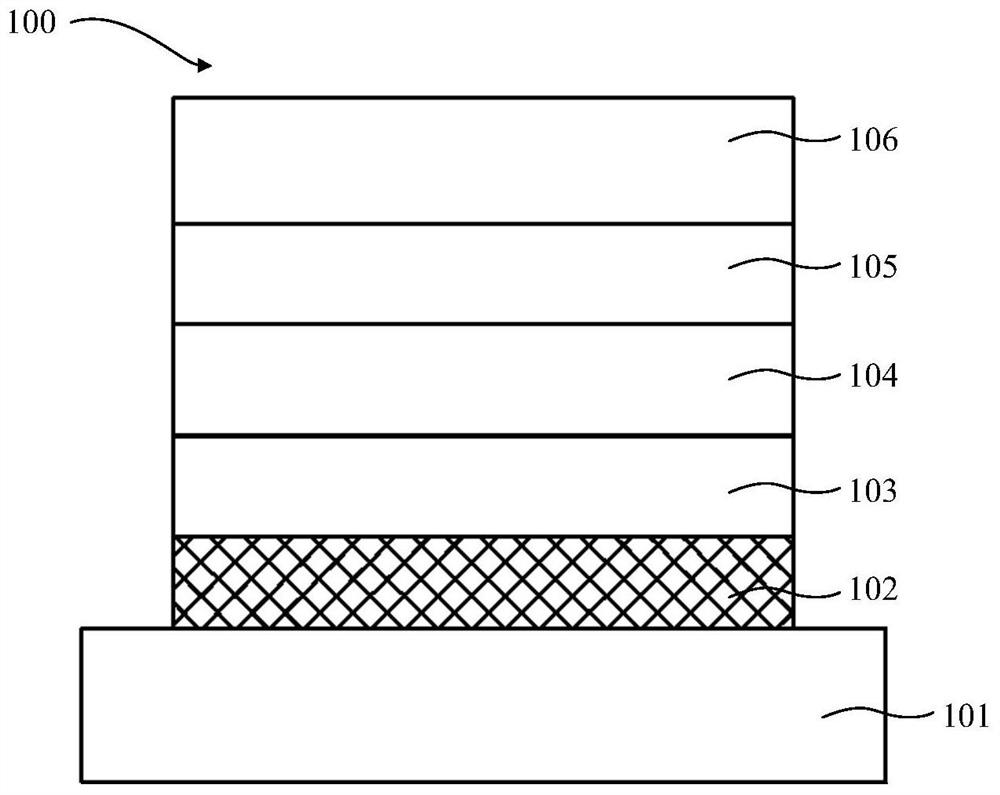

[0037] Such as figure 1 As shown, this embodiment provides an organic light emitting diode 100, the organic light emitting diode 100 is a top emission organic light emitting diode, the organic light emitting diode 100 includes: an anode layer 101, a hole injection layer 102, a hole transport layer 103 , the light emitting layer 104, the electron transport layer 105, and the cathode layer 106.

[0038] Wherein, the hole injection layer 102 is arranged on the surface of one side of the anode layer 101, and the hole injection layer 102 is used to inject holes from the cathode into the OLED device; the hole transport layer 103 is arranged on the hole The hole injection layer 102 is away from the surface of the anode layer 101 side, and the hole transport layer 103 is used to transport the holes injected into the OLED from the hole injection layer 102 to the light-emitting layer; the light-emitting layer 104 is arranged on the The surface of the hole transport layer 103 away from ...

Embodiment 2

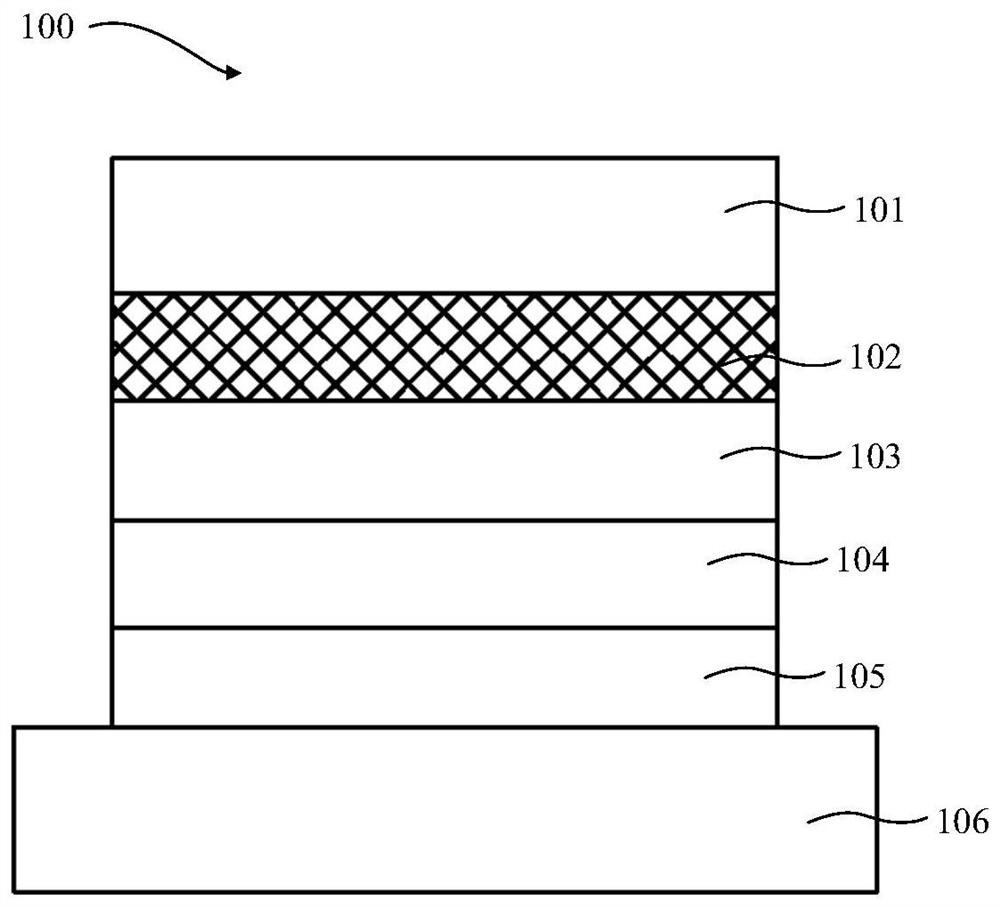

[0049] Such as figure 2 As shown, this embodiment provides an organic light emitting diode 100. The difference between the second embodiment of the present application and the first embodiment of the present application is that the organic light emitting diode 100 is a bottom-emitting organic light emitting diode; wherein, the The OLED 100 includes a cathode layer 106 , an electron transport layer 105 , a light emitting layer 104 , a hole transport layer 103 , a hole injection layer 102 and an anode layer 101 stacked from bottom to top.

[0050] Aiming at the technical problem of low efficiency of organic light emitting diodes prepared with p-type doped materials in the prior art, the embodiment of the present application provides a bottom emission type organic light emitting diode, the organic light emitting diode adopts poly(3,4-ethylene Dioxythiophene): The polymer host material composed of an aqueous solution of polystyrene sulfonate (PEDOT:PSS) and the additive material ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electron work function | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com