Composite positive electrode lithium supplement additive and preparation method and application thereof

A composite positive electrode and composite lithium supplement technology, which is applied in the field of lithium-ion batteries, can solve the problems of high environmental requirements, unsatisfactory use, and poor rate performance, and achieve the effects of efficiently supplementing lithium, compensating for voltage mismatch, and improving rate characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

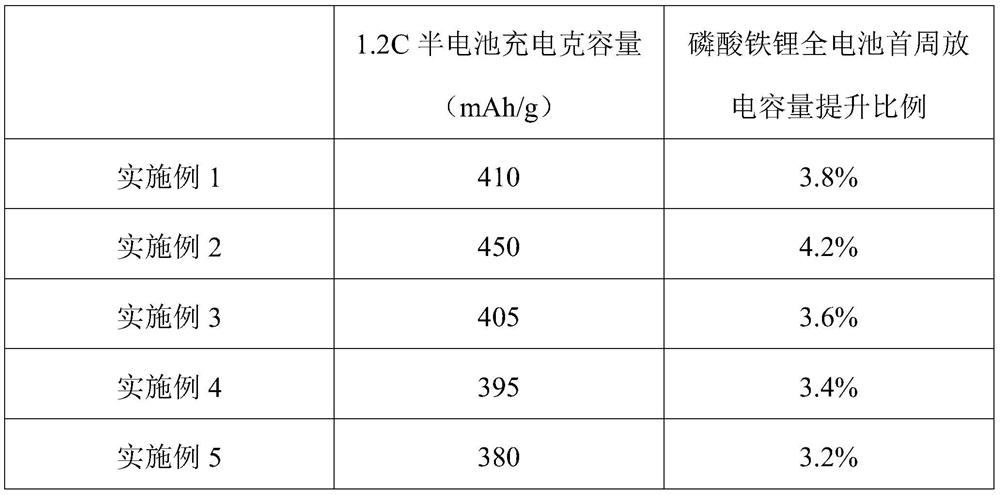

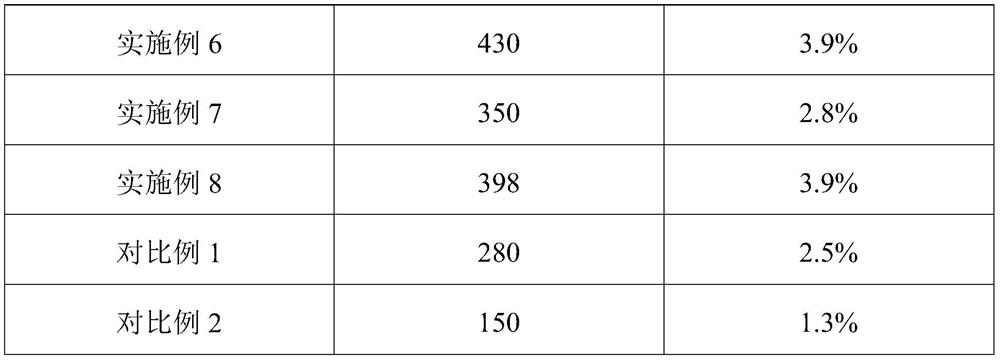

Examples

Embodiment 1

[0039] This embodiment provides a composite positive electrode lithium supplement additive, which is prepared by the following method:

[0040] (1) Take Li 2 NiO 2 According to the ball-to-material ratio of 50:1, high-energy ball milling was carried out at 300rpm for 12h to obtain Li with a median particle size D502 NiO 2 ;

[0041] (2) Li 2 NiO 2 Mixed with KS-6 according to the mass ratio of 97:3, ball milled at 350rpm for 3h to obtain the composite cathode lithium supplement additive.

Embodiment 2

[0043]This embodiment provides a composite positive electrode lithium supplement additive, which is prepared by the following method:

[0044] (1) Take Li 5 FeO 4 According to the ball-to-material ratio of 80:1, jet milling is carried out at 0.6MPa airflow pressure and temperature 150°C, and the particles are classified to obtain Li with a median particle size of D505 FeO 4 ;

[0045] (2) Li 5 FeO 4 Mix with conductive carbon black SP according to the mass ratio of 98:2, and ball mill at 350rpm for 2.5h to obtain the composite positive electrode lithium supplement additive.

Embodiment 3

[0047] The only difference between this embodiment and Example 1 is that Li 2 NiO 2 And the mass ratio of KS-6 is 99:1, and other conditions and parameter are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com