Supported CoxMy intermetallic compound catalyst as well as preparation and use methods thereof

A technology of intermetallic compounds and catalysts, which is applied in the field of catalysis, can solve the problems of catalyst active metal loss and metal loss, and achieve the effect of avoiding the loss of active metals, cobalt loss, separation of catalysts and products and recycling problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0087] Exemplary embodiments of the present invention are described below, in which various details of the embodiments of the present invention are included to facilitate understanding, and should be considered as exemplary only. Accordingly, those of ordinary skill in the art will recognize that various changes and modifications of the embodiments described herein can be made without departing from the scope and spirit of the invention. Also, descriptions of well-known functions and constructions are omitted in the following description for clarity and conciseness.

[0088] The reagents, materials and devices used in the following examples can be purchased commercially unless otherwise specified.

preparation example 1

[0089] Preparation Example 1 Co content 3wt% Co 1 Ga 1 / SiO 2 Catalyst preparation

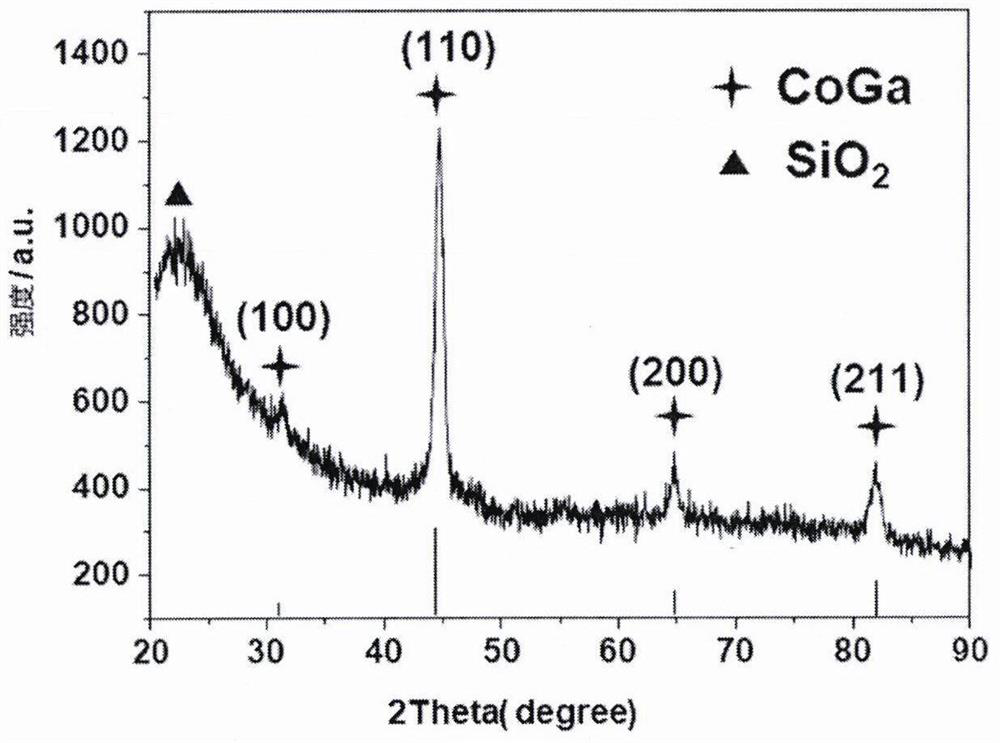

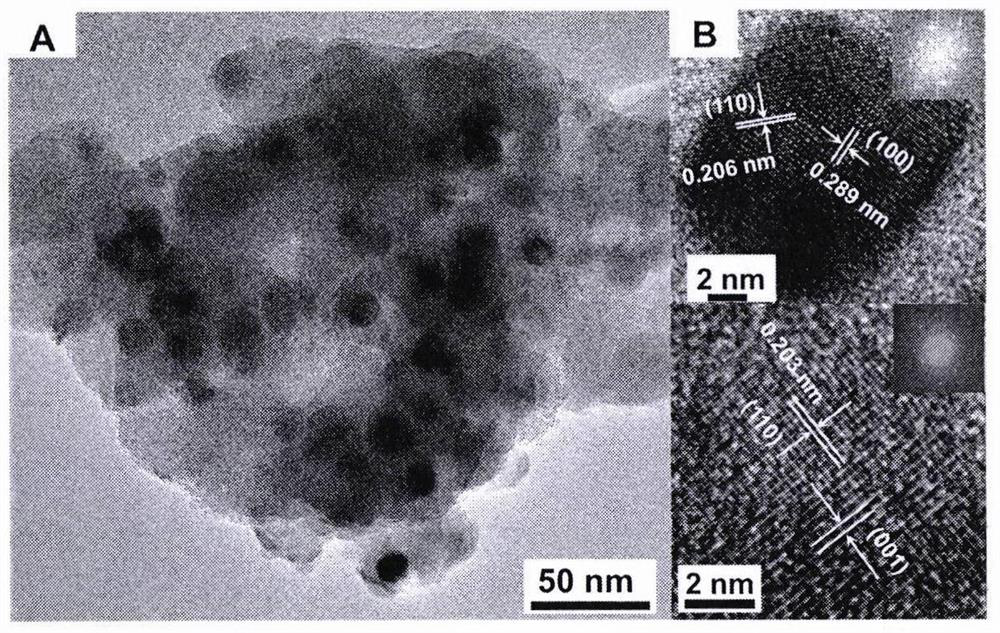

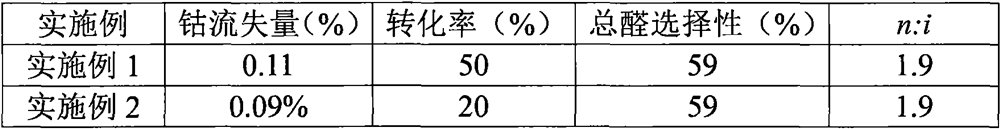

[0090] Weigh 0.75g Co(NO 3 ) 2 ·6H 2 O and 0.66g Ga(NO 3 ) 2 ·xH 2 O (purchased from Aladdin, analytically pure) and dissolved in 200 g deionized water to obtain 2+ and Ga 3+ of salt solution. Weigh 5.0g SiO2 2 Carrier (specific surface area 150m 2 / g, pore volume 0.9m 3 / g, average pore diameter 23.4nm) and immersed in the above solution, stirred at room temperature for 12h, and then rotary evaporated at 50°C to remove the deionized water from the resulting mixed solution to obtain a powdery solid mixture. The solid mixture was heated in a tube furnace under H 2 Under the atmosphere, the temperature was raised to 900°C at a rate of 2°C / min, and reduced at this temperature for 2 hours, wherein the hydrogen flow rate was 50ml / min, and the reduced catalyst was Co with a Co content of 3wt%. 1 Ga 1 / SiO 2 catalyst. Among them, the XRD pattern and transmission electron microscope im...

preparation example 2

[0091] Preparation Example 2 Co with a Co content of 1wt% 1 Ga 1 / C 3 N 4 Catalyst preparation

[0092] Weigh 0.25g Co(NO 3 ) 2 ·6H 2 O and 0.22g Ga(NO 3 ) 2 ·xH 2 O and dissolved in 200 g deionized water to obtain Co 2+ and Ga 3+ of salt solution. Weigh 5.0g C 3 N 4 Carrier (specific surface area 10m 2 / g, pore volume 0.05m 3 / g, average pore diameter 12nm) and immersed in the above solution, stirred at room temperature for 12h, and then rotary evaporated at 50°C to remove the deionized water from the resulting mixed solution to obtain a powdery solid mixture. The solid mixture was heated in a tube furnace under H 2 Under the atmosphere, the temperature was raised to 800°C at a rate of 3°C / min, and reduced at this temperature for 3h, wherein the hydrogen flow rate was 50ml / min, and the reduced catalyst was Co with a Co content of 1wt%. 1 Ga 1 / C 3 N 4 catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com