Bio-based leather filler and preparation method thereof

A bio-based, leather technology, applied in small raw hide/large raw hide/leather/fur treatment, small raw hide/large raw hide/leather hide/fur chemical treatment, waste treatment, etc. The problems of poor ecological sustainability of raw materials, cumbersome preparation process, etc., can achieve the effects of improving permeability and binding ability, good retanning and filling effect, and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

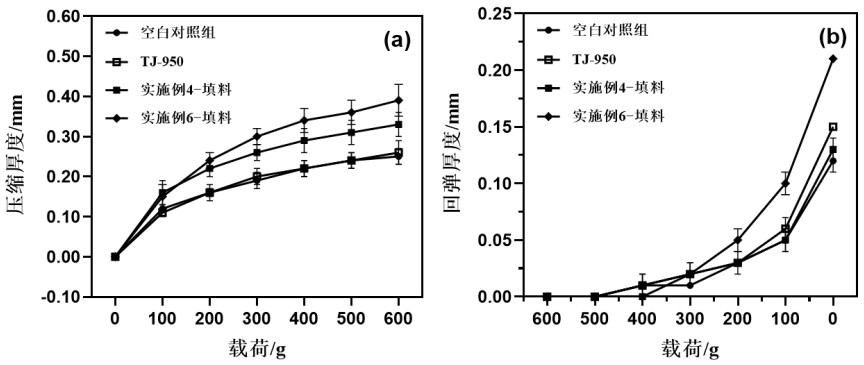

Image

Examples

Embodiment 1

[0033] A method for preparing a bio-based leather filler, comprising: using chrome-free tanned waste leather scraps as raw materials, fully mixing it with water, raising the temperature to 60-90 ºC, and then adding a catalyst, an acid and an oxidizing agent to perform a degradation reaction for 0.5- 2 h.

[0034] Wherein, in parts by weight, the chrome-free tanned waste leather scraps are 100 parts, the water is 200-1000 parts, the catalyst is 0.05-0.2 parts, the acid is 0-20 parts, and the oxidizing agent is 20-100 parts.

[0035] The chrome-free tanned waste leather shavings are at least one of chrome-free metal tanning agent tanned waste leather shavings, organic tanned waste leather shavings, and combined tanned waste leather shavings. Preferably, the waste leather shavings tanned by the non-chromium metal tanning agent are at least one of waste leather shavings tanned by zirconium tanning agents, waste leather shavings tanned by aluminum and zirconium; At least one of ve...

Embodiment 2

[0045] A preparation of bio-based leather filler:

[0046] Take 100 parts of zirconium tanned waste leather shavings, add 200 parts of water, mix well, raise the temperature to 90 ºC, add 0.04 parts of ferrous sulfate, 0.01 parts of copper sulfate, 5 parts of sulfuric acid, 50 parts of hydrogen peroxide, and react for 1 h to obtain the first a mixed solution;

[0047] Add 2 parts of formylated carboxymethyl cellulose to the first mixed solution under stirring, after fully mixing, control the temperature to 50 ºC, adjust the pH of the reaction system to 7.0, and react for 2 h to obtain the second mixed solution; and

[0048] Add 2 parts of sodium bisulfite to the second mixed solution, continue the reaction for 0.5 h, and obtain the bio-based leather filler after drying.

Embodiment 3

[0050] A preparation of bio-based leather filler:

[0051] Take 100 parts of alginated sodium alginate tanned waste leather shavings, add 400 parts of water, mix thoroughly, heat up to 60 ºC, add 0.2 parts of sodium tungstate, 10 parts of hydrochloric acid, 100 parts of hydrogen peroxide, and react for 2 hours to obtain the first a mixed solution;

[0052] Control the temperature to 50-80 ºC, adjust the pH of the reaction system to 8.0, and react for 4 h to obtain the second mixed solution; and

[0053] Add 4 parts of sodium sulfite to the second mixed solution, continue to react for 1 h, and obtain bio-based leather filler after drying.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com