Chemical fiber oiling agent composition for POY production and preparation method thereof

A chemical fiber oil and composition technology, applied in the field of fiber processing, can solve the problems of poor heat resistance of the oil, poor use effect of the oil, volatilization and the like, and achieve the effects of improving lubrication, enhancing toughness and enhancing heat resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

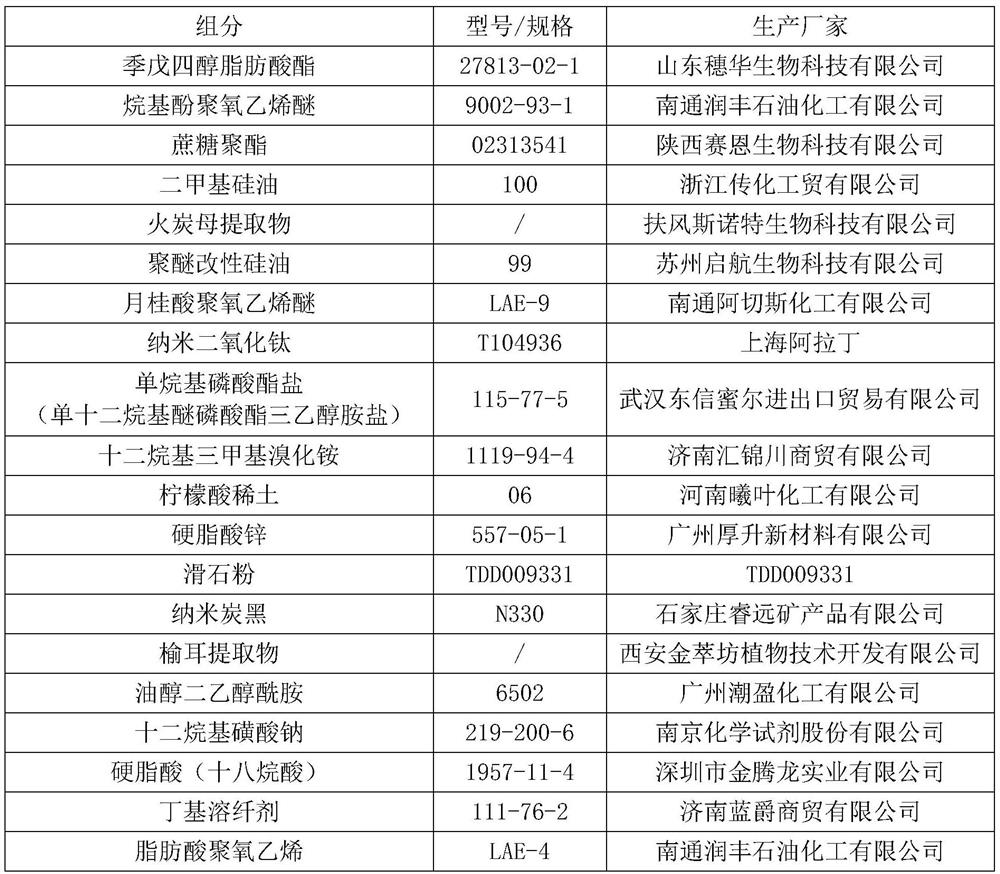

Image

Examples

Embodiment 1

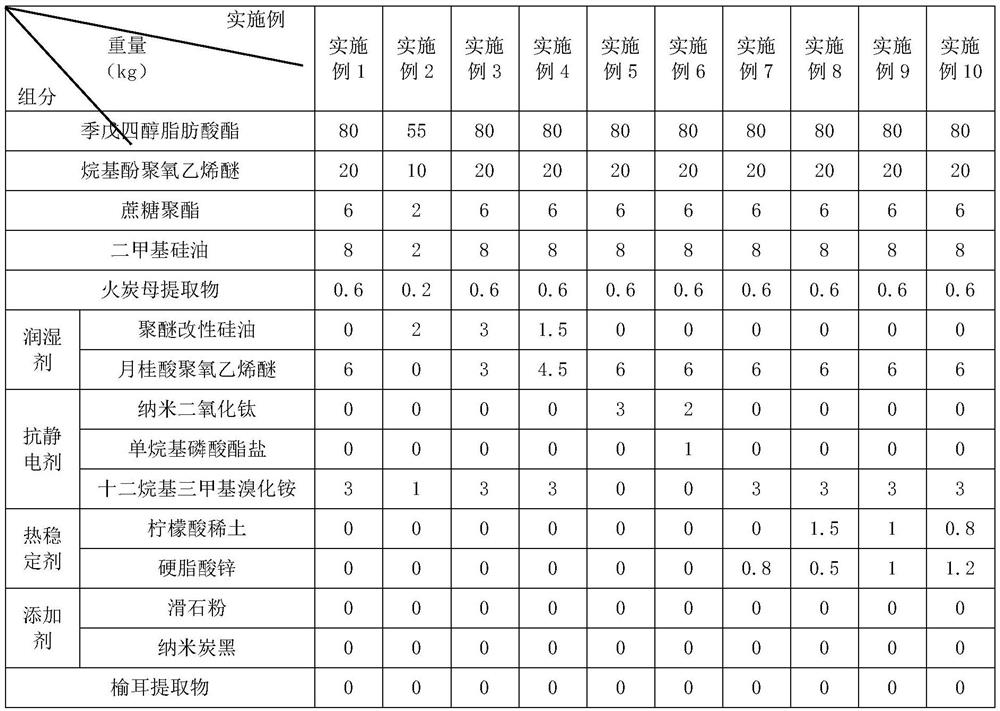

[0045] Embodiment 1: a kind of chemical fiber oil composition that is used for POY production, the concrete component that comprises and weight are as shown in table 2, are made by following steps:

[0046] S1: Mix and stir pentaerythritol fatty acid ester, alkylphenol polyoxyethylene ether, and sucrose polyester at a stirring speed of 150r / min. After stirring evenly, add simethicone oil and fire charcoal mother extract and mix and stir at a stirring speed of 120r / min. min, stir evenly to obtain the first mixture;

[0047] S2: Mix and stir the first mixture with the wetting agent and the antistatic agent at a stirring speed of 150 r / min, and stir evenly to obtain a chemical fiber oil composition for POY production.

Embodiment 2

[0048] Embodiment 2: a kind of chemical fiber oil composition that is used for POY production, the difference with embodiment 1 is that specific components and weight are different, and the specific components and weight that comprise are as shown in table 2.

Embodiment 3-4

[0049] Embodiment 3-4: a kind of chemical fiber oil composition that is used for POY production, and the difference of embodiment 1 is that the specific components and weight of wetting agent are different, and the specific components and weight that comprise are as shown in Table 2 Show.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com