Method for preparing porous nanoparticle/polydimethylsiloxane membrane through water surface spreading

A technology of dimethylsiloxane membrane and polydimethylsiloxane, which is applied in the field of membrane separation, can solve the problems of easy falling off of particles, inability to control the phenomenon of liquid casting and seepage, and reduced operation stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Membrane preparation method:

[0032] (1) Pre-crosslinking of polydimethylsiloxane casting solution

[0033] Dissolve 2g of polydimethylsiloxane in 18g of n-heptane, stir for 3 hours, add 0.2g of crosslinking agent ethyl orthosilicate, stir for a period of time, add 0.005g of dibutyltin dilaurate, in a water bath at 60°C Stir in medium for 3h;

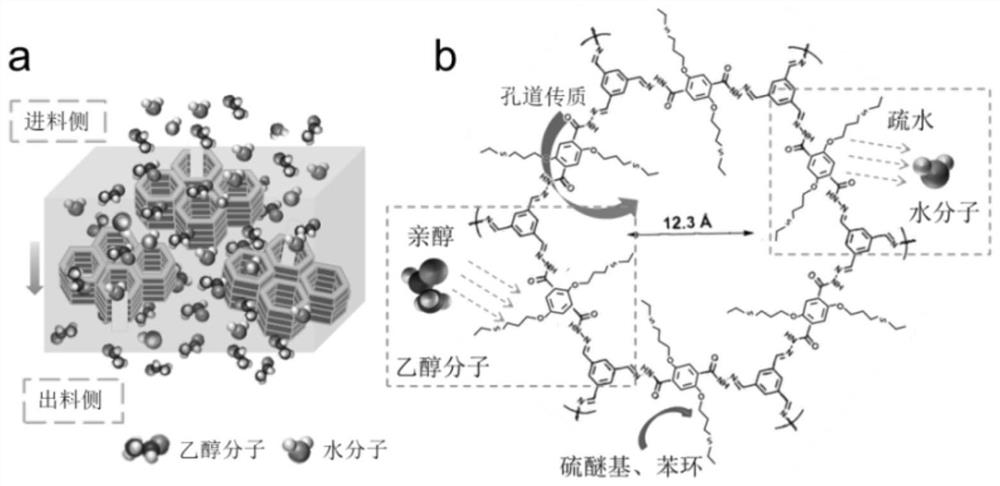

[0034] (2) Pre-crosslinking of covalent organic framework COF-LZU8 / polydimethylsiloxane casting solution

[0035] Add 0.05wt% covalent organic framework COF-LZU8 particles into the polydimethylsiloxane casting solution, continue to stir for 30 minutes, and sonicate for 30 minutes, repeating 3 times.

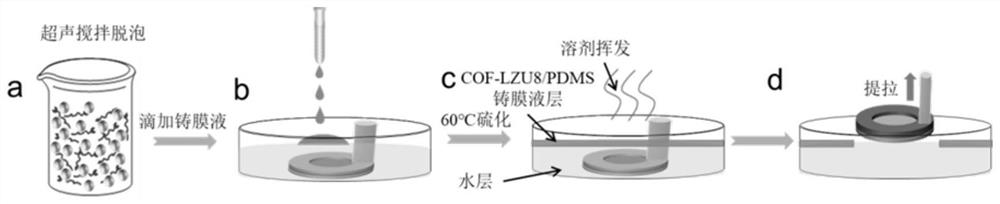

[0036] (3) Preparation of covalent organic framework COF-LZU8 / polydimethylsiloxane composite film by water surface spreading method

[0037]Rinse the surface of the polysulfone base membrane (20nm pore size) with deionized water for 1min, place it in a vacuum filter bottle equipped with deionized water and filter it for 5h; pour...

Embodiment 2

[0040] Membrane preparation method:

[0041] (1) Pre-crosslinking of polydimethylsiloxane casting solution

[0042] Dissolve 2g of polydimethylsiloxane in 18g of n-heptane, stir for 3 hours, add 0.2g of crosslinking agent ethyl orthosilicate, stir for a period of time, add 0.005g of dibutyltin dilaurate, in a water bath at 60°C Stir in medium for 3h;

[0043] (2) Pre-crosslinking of covalent organic framework COF-LZU8 / polydimethylsiloxane casting solution

[0044] Add 0.1wt% covalent organic framework COF-LZU8 particles into the polydimethylsiloxane casting solution, continue to stir for 30 minutes, and sonicate for 30 minutes, repeating 3 times.

[0045] (3) Preparation of covalent organic framework COF-LZU8 / polydimethylsiloxane composite film by water surface spreading method

[0046] Rinse the surface of the polysulfone base membrane (20nm pore size) with deionized water for 1min, place it in a vacuum filter bottle equipped with deionized water and filter it for 5h; pour...

Embodiment 3

[0049] Membrane preparation method:

[0050] (1) Pre-crosslinking of polydimethylsiloxane casting solution

[0051] Dissolve 2g of polydimethylsiloxane in 18g of n-heptane, stir for 3 hours, add 0.2g of crosslinking agent ethyl orthosilicate, stir for a period of time, add 0.005g of dibutyltin dilaurate, in a water bath at 60°C Stir in medium for 3h;

[0052] (2) Pre-crosslinking of covalent organic framework COF-LZU8 / polydimethylsiloxane casting solution

[0053] Add 0.15wt% covalent organic framework COF-LZU8 particles into the polydimethylsiloxane casting solution, continue to stir for 30 minutes, and sonicate for 30 minutes, repeating 3 times.

[0054] (3) Preparation of covalent organic framework COF-LZU8 / polydimethylsiloxane composite film by water surface spreading method

[0055] Rinse the surface of the polysulfone base membrane (20nm pore size) with deionized water for 1min, place it in a vacuum filter bottle equipped with deionized water and filter it for 5h; pou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com