Chimney special high temperature anti-corrosion coating and composite resin glass fiber reinforced plastic spraying process

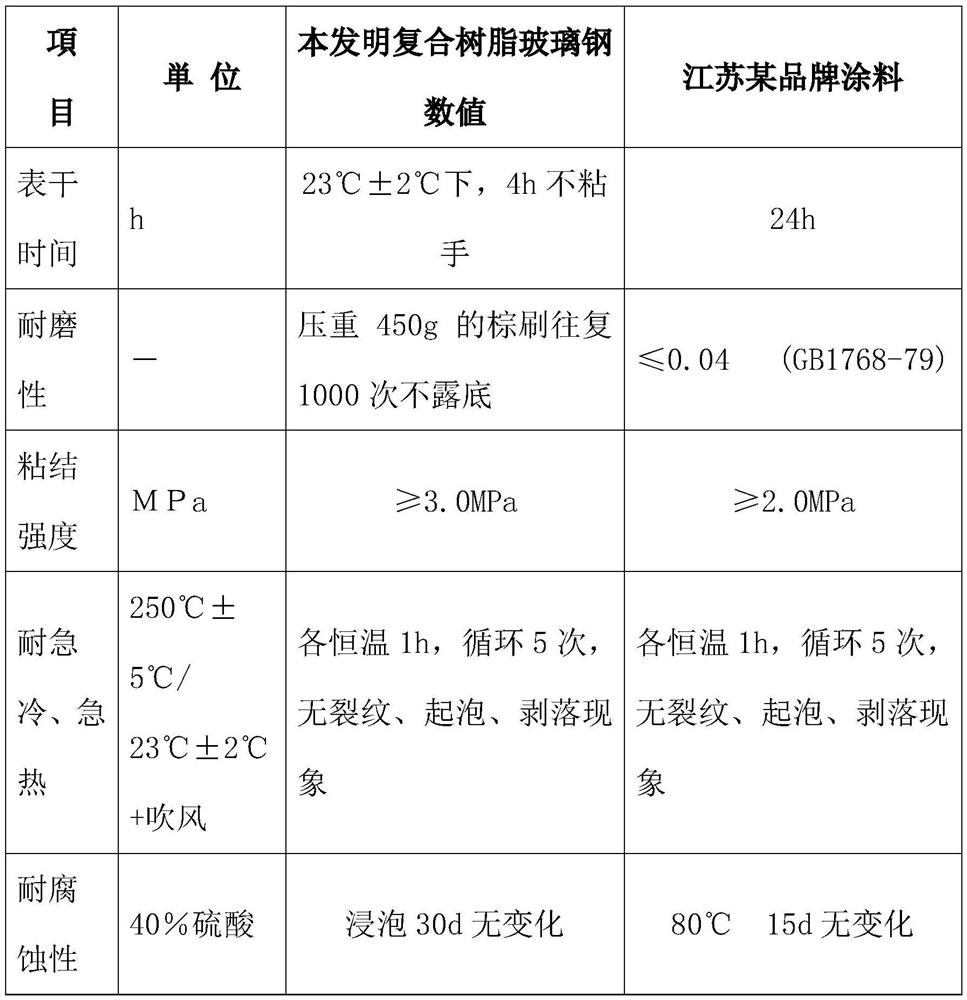

A composite resin, anti-corrosion spraying technology, applied in anti-corrosion coatings, fire-retardant coatings, asphalt coatings, etc., can solve the problems of poor anti-aging performance, short service life, low bonding strength, etc., achieve good corrosion resistance, low cost, The effect of short renovation period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

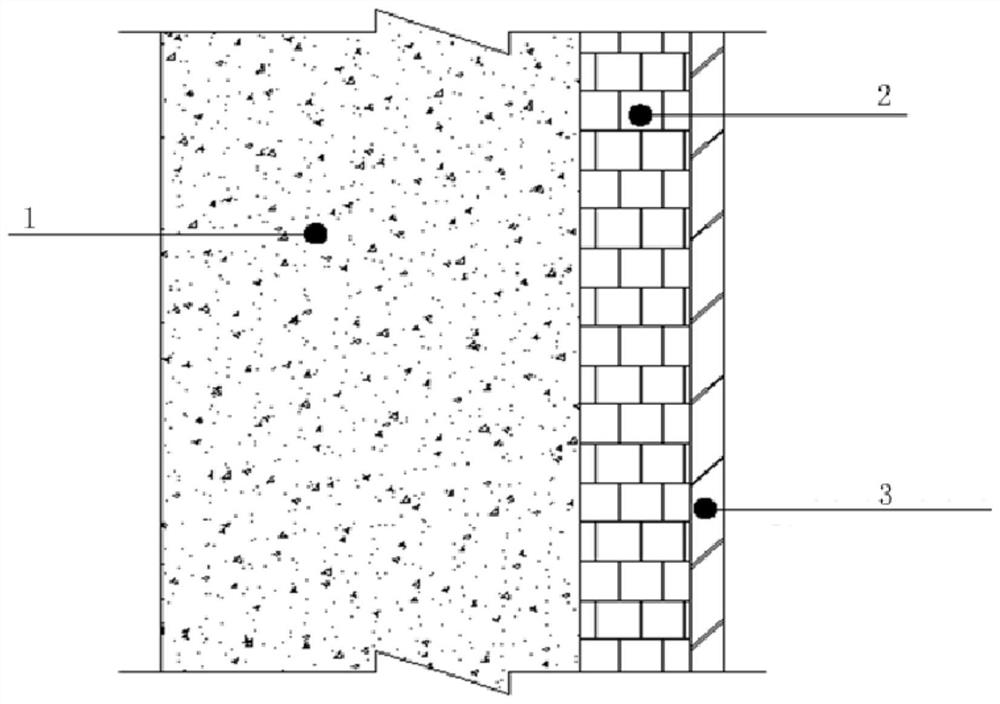

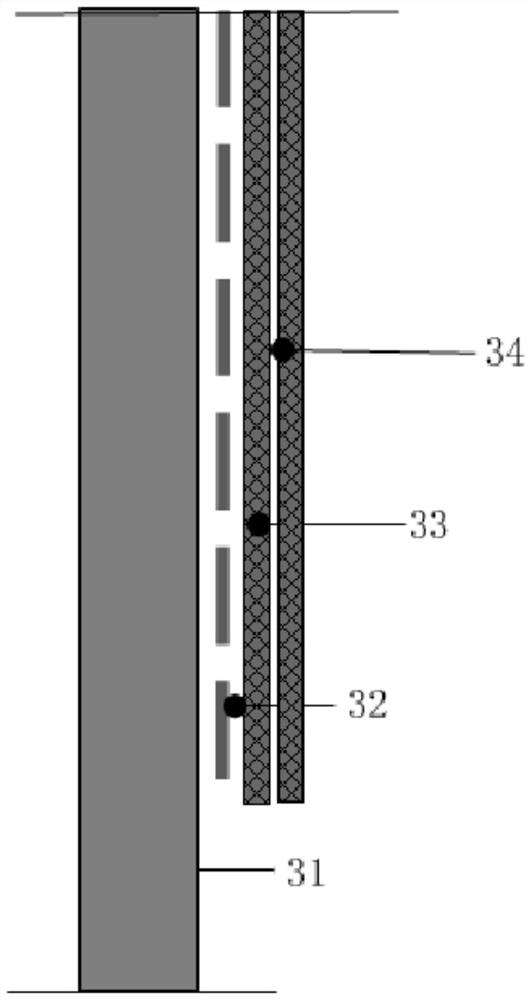

[0034] An anti-corrosion spraying process for old concrete chimneys adopts high temperature resistant composite resin glass fiber reinforced plastic coating, and the construction process is as follows:

[0035] Surface treatment of the base layer: Use special tools to clean the surface of the inner lining and use the sandblasting process to knock off the residue to expose the clean inner lining surface (individually corroded and fluffy bricks should be dug up for local treatment), and finally use high pressure Water for rinsing and dust removal.

[0036] Treatment of the surface flatness of the lining: The corroded parts should be removed and filled in time with dilute acid-resistant mortar. First, use the special mortar for dilute acid resistance to carry out a general batch wiping on the lining surface, so that the anti-corrosion base surface forms a relatively flat surface, and fill the brick joints once to prevent the desulfurization condensate from seeping out through the...

Embodiment 2

[0042] The process is the same as that of Example 1, and the parameter difference is as follows:

[0043] The thickness of the mortar layer during the treatment of the surface flatness of the inner lining is 12mm, and the thickness of the structure layer of the composite resin coating is 1.4mm. The raw materials of the composite resin coating include 30 parts by mass of modified silicone resin, 8 parts by mass of fumed silica, 12 parts by mass of graphite powder, 20 parts by mass of xylene, 20 parts by mass of active thinner, 8 parts by mass of refined coal tar, defoaming 2 parts by mass of agent and 3 parts by mass of imported curing agent.

Embodiment 3

[0045] The process is the same as that of Example 1, and the parameter difference is as follows:

[0046] The thickness of the mortar layer in the treatment of the surface flatness of the inner lining is 15mm, and the thickness of the structure layer of the composite resin coating is 1.5mm. The raw materials of the composite resin coating include 40 parts by mass of modified silicone resin, 10 parts by mass of fumed silica, 15 parts by mass of graphite powder, 20 parts by mass of xylene, 25 parts by mass of active thinner, 10 parts by mass of refined coal tar, defoaming 2 parts by mass of agent and 3 parts by mass of imported curing agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| amine value | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com