Silver-loaded graphene/copper self-lubricating material and preparation method thereof

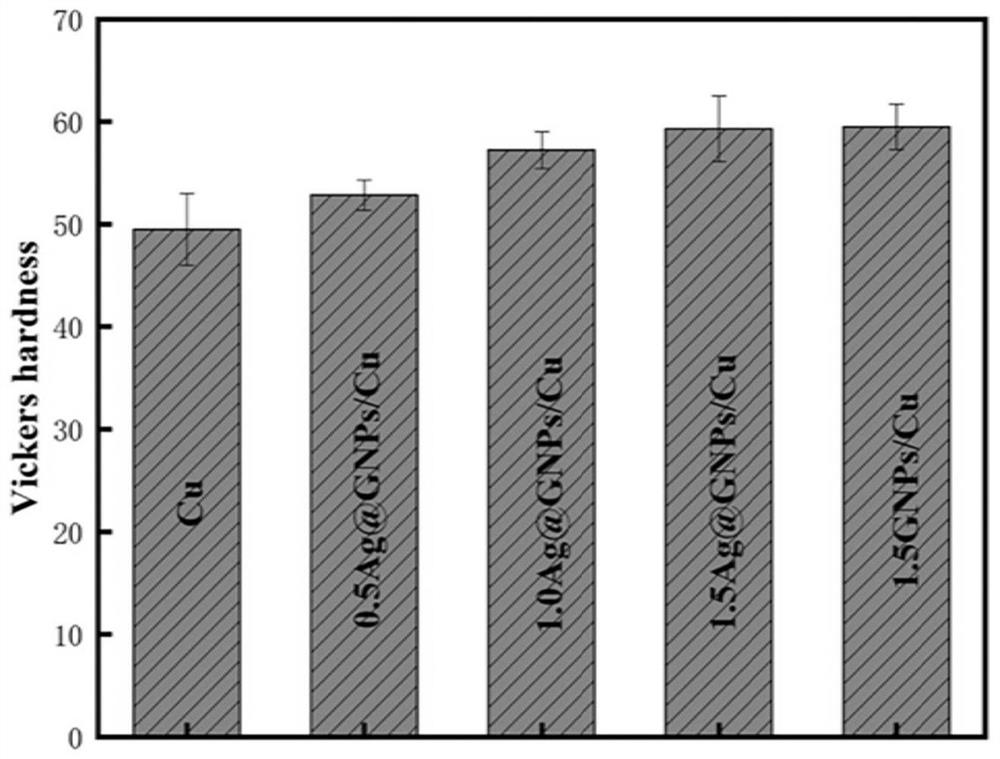

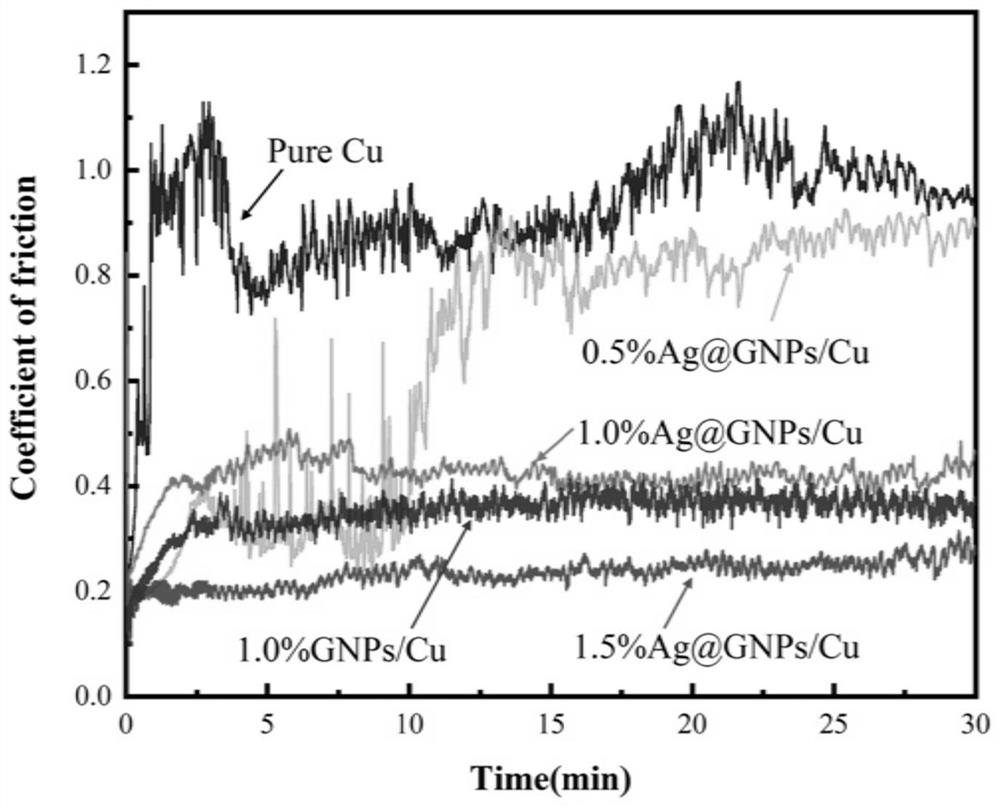

A self-lubricating material, graphene technology, applied in chemical instruments and methods, nanotechnology for materials and surface science, inorganic chemistry, etc., can solve problems such as agglomeration, wrinkling, deterioration of material use, etc., to achieve increased hardness, friction The effect of decreasing the coefficient and improving dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

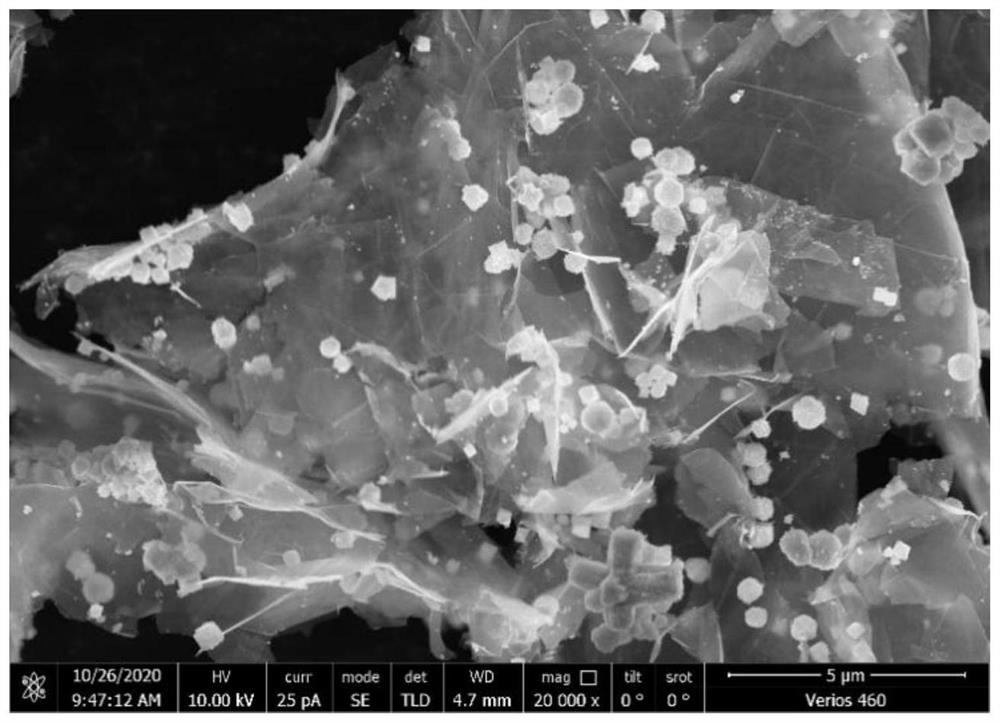

Image

Examples

preparation example Construction

[0031] A kind of preparation method of the graphene / copper self-lubricating material loaded with silver of the present invention comprises the following steps:

[0032] Step 1: Weigh 0.05-0.15g of graphene nanosheets with 5-15 layers, 0.05-0.15g of sodium lauryl sulfate, stir and mix, add to 30-50ml of dimethylformamide, and ultrasonically disperse for 100 ~140min.

[0033] Step 2: Prepare 1mol / L~4mol / L AgNO 3 solution.

[0034] Step 3: Mix 8-15ml of the AgNO in Step 2 3 Pour the solution into the mixed liquid after ultrasonic dispersion in step 1, and then ultrasonically disperse for 2-3 hours.

[0035] Step 4: Heating the mixed solution in Step 3 at 60-90° C. for 0.5-2 hours; washing with deionized water and absolute ethanol in sequence, filtering and drying to obtain silver-loaded graphene.

[0036] Step 5: Take a certain amount of copper powder with a 325-mesh sieve, i.e. copper powder and silver-loaded graphene with a particle size below 0.0450mm, so that the silver-l...

Embodiment 1

[0043] A silver-loaded graphene / copper-based friction material of the present invention specifically comprises the following steps:

[0044] Step 1: Weighing 0.1 g of graphene nanosheets with 5 to 15 layers, and weighing 0.1 g of sodium lauryl sulfate powder at the same time. Stir and mix the weighed graphene nanosheets and sodium lauryl sulfate powder with a glass rod to obtain a mixed powder. Measure 30ml of dimethylformamide liquid, pour it into the above mixed powder, stir and ultrasonically disperse for 120min to obtain a mixed liquid.

[0045] Step 2. Weigh 1.7gAgNO 3 powder, dissolved in 10ml deionized water to prepare 1mol / L AgNO 3 solution, and then poured into the mixed liquid obtained in step 1, stirred, and ultrasonically dispersed for 30 minutes.

[0046]Step 3. Put the mixed solution obtained in Step 2 into a water bath heater, heat it from room temperature to 70° C., and keep it warm for 30 minutes.

[0047] Step 4, the liquid heated in a water bath is left ...

Embodiment 2

[0075] A silver-loaded graphene / copper-based friction material of the present invention specifically comprises the following steps:

[0076] Step 1: Weighing 0.1 g of graphene nanosheets with 5 to 15 layers, and weighing 0.1 g of sodium lauryl sulfate powder at the same time. Stir and mix the weighed graphene nanosheets and sodium lauryl sulfate powder with a glass rod to obtain a mixed powder. Measure 40ml of dimethylformamide liquid, pour it into the above mixed powder, stir and ultrasonically disperse for 110min to obtain a mixed liquid.

[0077] Step 2. Weigh 3.4gAgNO 3 powder, dissolved in 10ml deionized water to prepare 2mol / L AgNO 3 solution, and then poured into the mixed liquid obtained in step 1, stirred, and ultrasonically dispersed for 2.5 hours.

[0078] Step 3. Put the mixed solution obtained in Step 2 into a water bath heater, heat it from room temperature to 60° C., and keep it warm for 1.5 hours.

[0079] Step 4, the liquid heated in a water bath is left t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com