Electromagnetic hypersonic thrust vector jet engine

A jet engine and hypersonic technology, applied in the direction of engine ignition, engine components, machines/engines, etc., can solve problems such as low thrust, inability to control the air inlet, and high technical difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

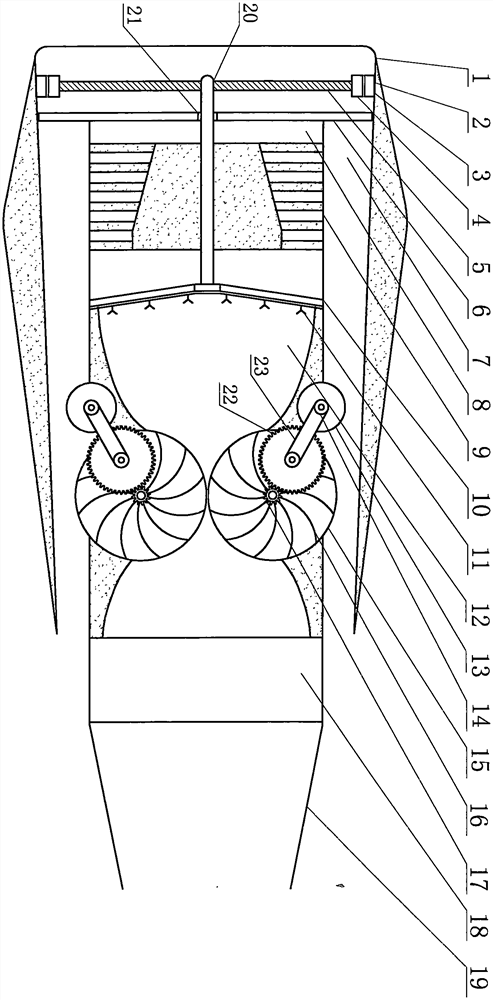

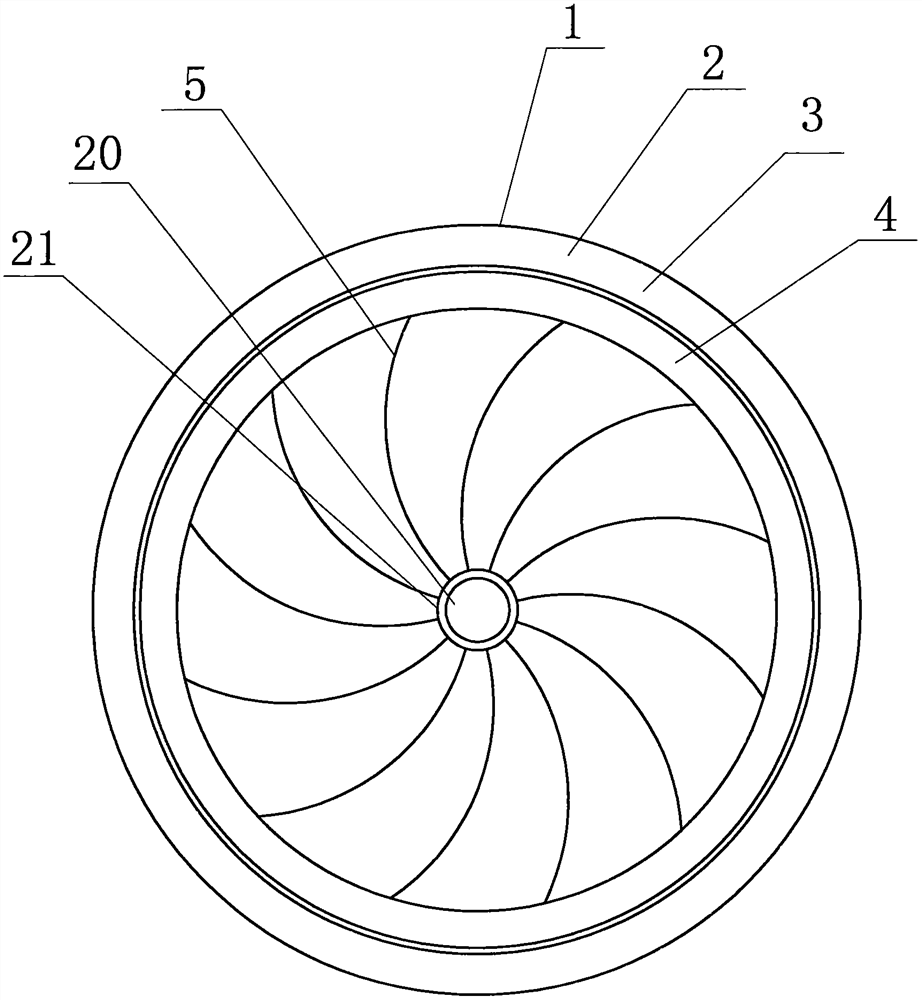

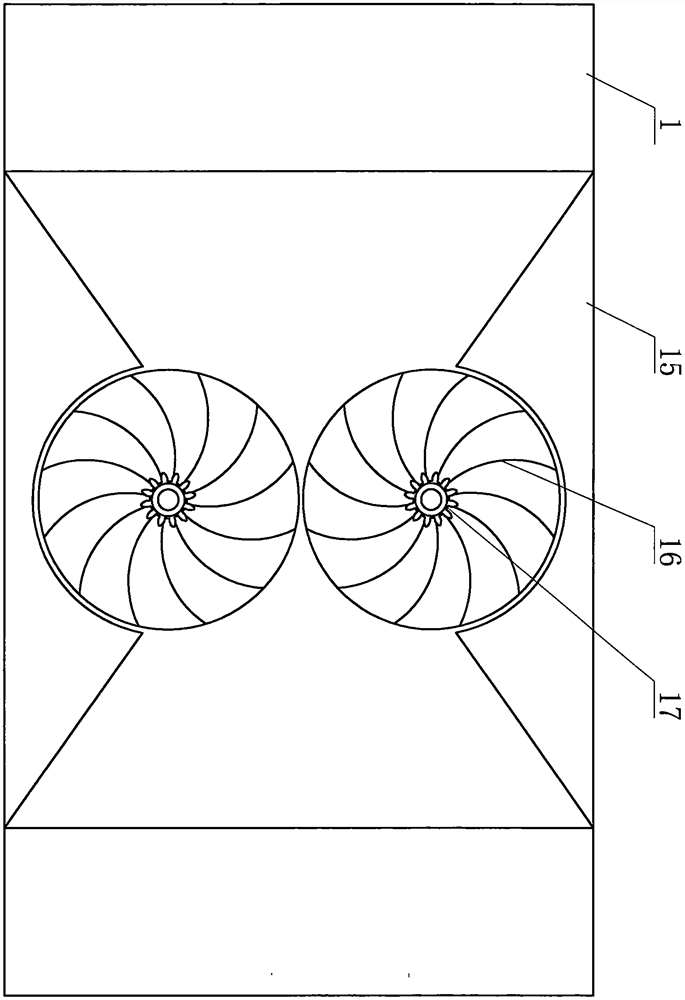

[0010] Such as figure 1 , 2As shown, an electromagnetic hypersonic thrust vector jet engine includes a casing 1, an adjustable air inlet, an electromagnetic turbofan 2, a stator 3, a permanent magnet rotor 4, a fan blade 5, a load-bearing frame 6, and an outer casing Road 7, inner channel 8, compressor 9, oxygen supply and oil supply pipe 10, afterburner nozzle 11, combustion chamber 12, generator 13, main shaft gear 14, twin-turbine engine, turbine 15, vortex blade 16, main shaft gear 17. Vector nozzle 18, adjustable nozzle 19, main shaft 20, bearing 21, lever gear 22, chain 23, connecting gear 24, frequency converter, transmission, spark plug, fuel injector, lithium battery, charger, computer, cable , instruments and electronic switches, the electromagnetic is composed of an armature and a permanent magnet, which uses the moving magnetic field generated by the current to drive the permanent magnet to rotate. The electromagnetic turbofan 2 is composed of a shell 1, a stator ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com