Composite packaging material with metal drawn wire on surface and preparation method of composite packaging material

A composite packaging material and surface metal technology, which is applied to the composite packaging material and its preparation field with surface metal wire drawing, and achieves the effects of convenient operation, stable quality and high production precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

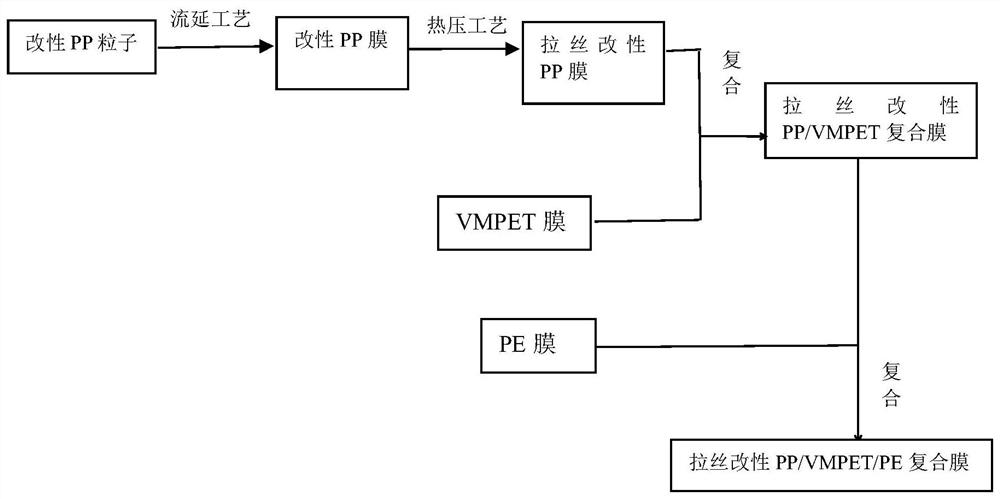

Method used

Image

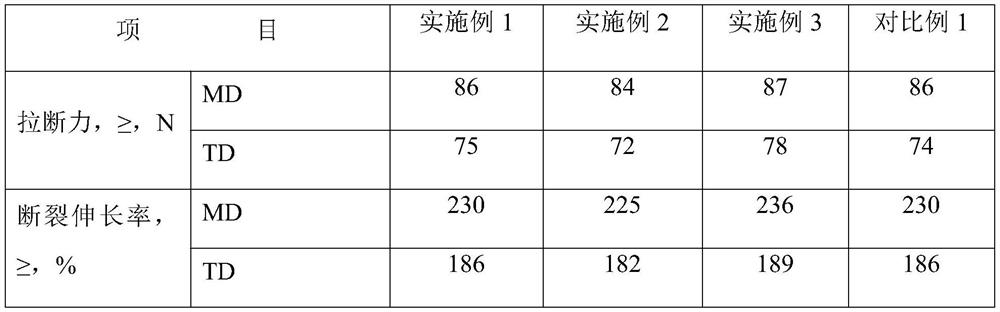

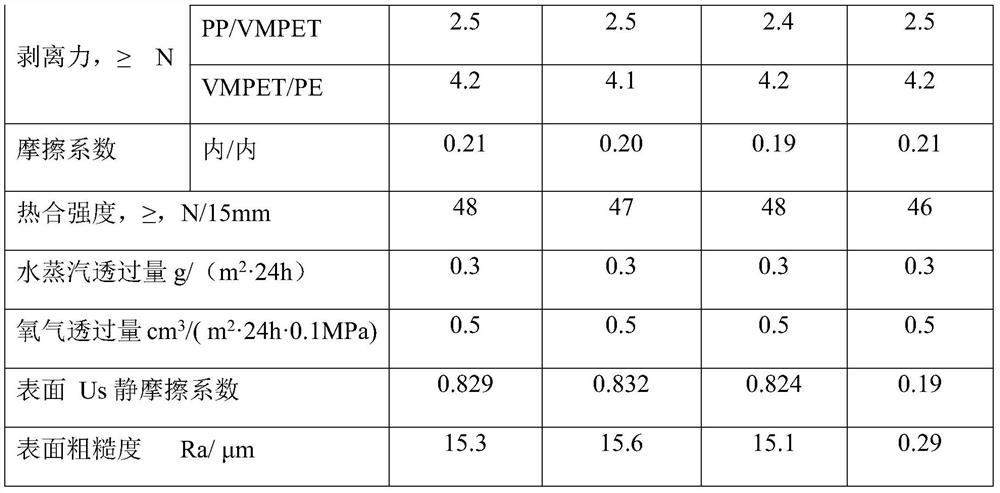

Examples

Embodiment 1

[0029] S1. Weigh the composition of the corona layer, intermediate layer and heat-sealing layer in the cast polypropylene film. Weigh the raw materials, wherein the corona layer consists of 80 parts by mass of high crystalline polypropylene homopolymer resin and 20 parts by mass of ternary Copolymerized polypropylene resin; the middle layer is composed of 100 parts by mass of high crystalline polypropylene homopolymeric resin; the heat-sealing layer is composed of 35 parts by mass of high crystalline polypropylene homopolymeric resin, 65 parts by mass of ternary copolymerized polypropylene resin, 0.15 The processing aid of mass parts, the smooth master batch of 1.0 mass parts, the opening master batch of 1.0 mass parts;

[0030] S2. Add the raw materials of the corona layer, intermediate layer and heat-sealing layer respectively into the three barrels of the co-extrusion casting equipment. 245°C, die head temperature 240°C, set the roll surface temperature of the casting roll ...

Embodiment 2

[0034]S1. Weigh the composition of the corona layer, intermediate layer and heat-sealing layer in the cast polypropylene film. Weigh the raw materials, wherein the corona layer consists of 80 parts by mass of high crystalline polypropylene homopolymer resin and 20 parts by mass of ternary Copolymerized polypropylene resin; the middle layer is composed of 100 parts by mass of high crystalline polypropylene homopolymeric resin; the heat-sealing layer is composed of 30 parts by mass of high crystalline polypropylene homopolymeric resin, 70 parts by mass of ternary copolymerized polypropylene resin, 0.1 The processing aid of mass part, the smooth masterbatch of 0.9 mass part, the opening masterbatch of 0.9 mass part is formed;

[0035] S2. Add the raw materials of the corona layer, intermediate layer and heat-sealing layer respectively into the three barrels of the co-extrusion casting equipment. 245°C, die head temperature 240°C, set the roll surface temperature of the casting ro...

Embodiment 3

[0039] S1. Weigh the composition of the corona layer, intermediate layer and heat-sealing layer in the cast polypropylene film. Weigh the raw materials, wherein the corona layer consists of 80 parts by mass of high crystalline polypropylene homopolymer resin and 20 parts by mass of ternary Copolymerized polypropylene resin; the middle layer is composed of 100 parts by mass of high crystalline polypropylene homopolymeric resin; the heat-sealing layer is composed of 40 parts by mass of high crystalline polypropylene homopolymeric resin, 60 parts by mass of ternary copolymerized polypropylene resin, 0.2 The processing aid of mass parts, the smooth masterbatch of 1.1 mass parts, the opening masterbatch of 1.1 mass parts composition;

[0040] S2. Add the raw materials of the corona layer, intermediate layer and heat-sealing layer respectively into the three barrels of the co-extrusion casting equipment. 245°C, die head temperature 240°C, set the roll surface temperature of the cast...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com