Pressure-sensitive conductive slurry and preparation method and application thereof

A technology of conductive paste and conductive filler, which is applied in conductive materials dispersed in non-conductive inorganic materials, conductive adhesives, cable/conductor manufacturing, etc. The effect of performance, high initial viscosity and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

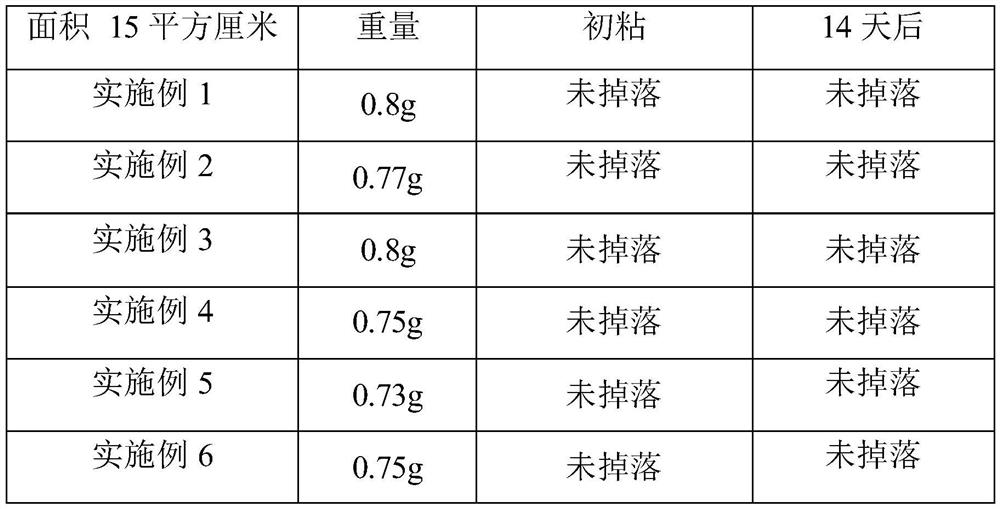

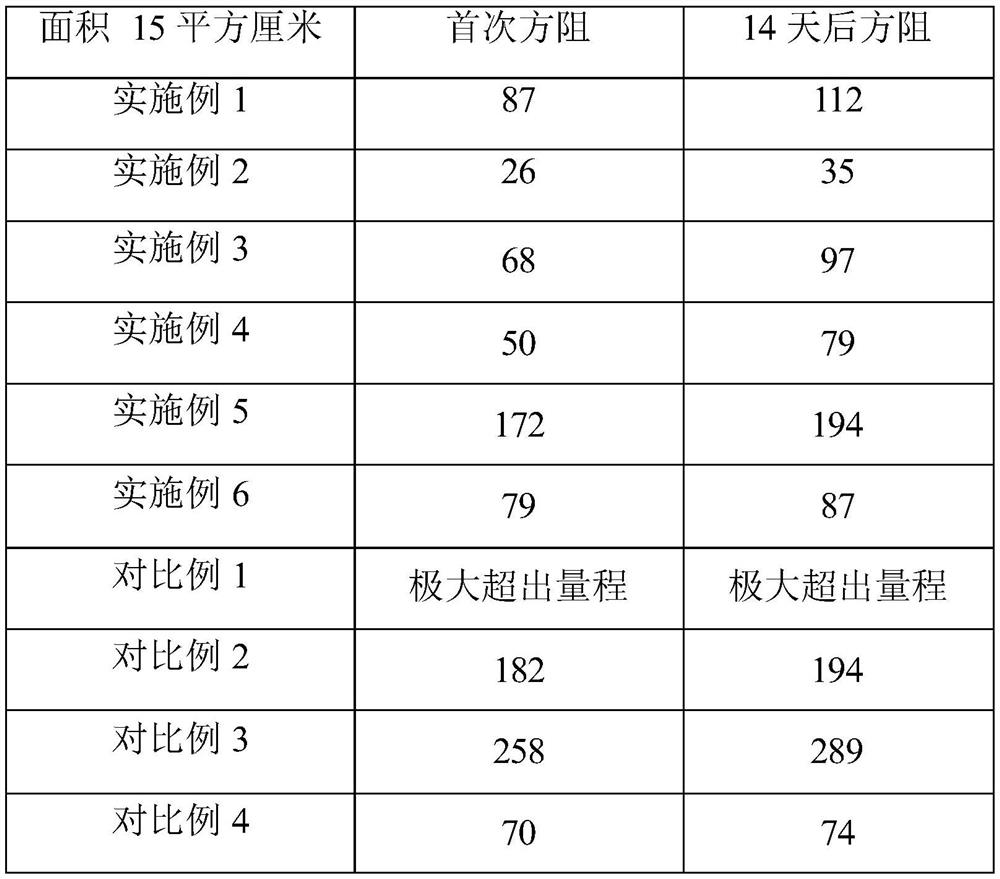

Examples

Embodiment 1

[0055] This embodiment provides a pressure-sensitive conductive paste, the raw materials of which include: 40 parts of the first silicone resin with an initial viscosity of 20000 Pa·s, 40 parts of the second silicone resin with an initial viscosity of 25000 Pa·s, granular carbon conductive 1 part of filler and 4 parts of carbon nanotube conductive filler.

[0056] Its preparation method includes:

[0057] S1. The first silicone resin and the carbon nanotube conductive filler were mixed for 10 minutes under the conditions of a stirring speed of 1500 rpm and a temperature of 30° C. by planetary gravity stirring to form a uniform black paste.

[0058] S2. The second silicone resin and the granular carbon conductive filler were mixed for 10 minutes under the conditions of planetary gravity stirring at a stirring speed of 1500 rpm and a temperature of 30° C. to form a brown liquid.

[0059] S3. The first system and the second system were mixed for 10 minutes under the conditions o...

Embodiment 2

[0061] This embodiment provides a pressure-sensitive conductive paste, the raw materials of which include: 40 parts of the first silicone resin with a viscosity of 20,000 Pa·s, 40 parts of the second silicone resin with a viscosity of 25,000 Pa·s, and 1 particle carbon conductive filler. 4 parts, 4 parts of carbon nanotube conductive filler, 8 parts of dispersant and 4 parts of montmorillonite.

[0062] Its preparation method includes:

[0063] S1. The first silicone resin, carbon nanotube conductive filler and dispersant were mixed by planetary gravity stirring for 10 minutes at a stirring speed of 1500 rpm and a temperature of 30° C. to form a uniform black paste.

[0064] S2. The second silicone resin, granular carbon conductive filler and montmorillonite were mixed by planetary gravity stirring for 10 minutes at a stirring speed of 1500 rpm and a temperature of 30° C. to form a brown liquid.

[0065] S3. The first system and the second system were mixed for 10 minutes und...

Embodiment 3

[0067] This embodiment provides a pressure-sensitive conductive paste, the raw material of which is the same as that of Embodiment 2, except that the addition positions of the dispersant and montmorillonite are different.

[0068] The preparation method of the present embodiment comprises:

[0069] S1. The first silicone resin and carbon nanotube conductive filler were mixed for 10 minutes under the conditions of planetary gravity stirring at a stirring speed of 1500 rpm and a temperature of 30° C. to form a uniform black paste.

[0070] S2. The second silicone resin and the granular carbon conductive filler were mixed for 10 minutes under the conditions of planetary gravity stirring at a stirring speed of 1500 rpm and a temperature of 30° C. to form a brown liquid.

[0071] S3. Mix the first system and the second system, then add dispersant and montmorillonite, and mix for 10 minutes under the conditions of stirring speed of 1500 rpm and temperature of 30° C. by means of plan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com