High-quality waveguide structure and preparation method

A waveguide structure, high-quality technology, applied in the direction of optical waveguide light guide, light guide, instrument, etc., can solve the problems of unrealizable, excellent optical performance, etc., and achieve the effect of low transmission loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

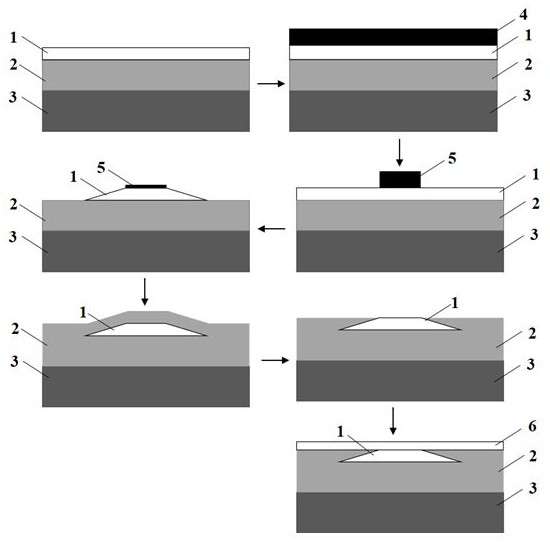

[0028] refer to figure 1 , the present invention utilizes femtosecond laser direct writing to combine chemical mechanical polishing technology and the method for preparing waveguide by bonding lithium niobate thin film to comprise the following steps:

[0029] (1) Prepare a lithium niobate wafer and plate a chromium film on its surface: take a 3-inch lithium niobate thin film wafer, which consists of a 300nm thick lithium niobate thin film 1 and a 4.7μm thick silicon dioxide layer 2 and a 0.5mm thick single crystal silicon substrate 3, and a chromium film 4 with a thickness of 400nm is plated on the surface of the lithium niobate film 1 by magnetron sputtering;

[0030] (2) Femtosecond laser direct writing chromium mask: Wipe the lithium niobate thin film wafer after the chromium coating layer 4 above with acetone to keep the cleanliness of the chromium film surface, and then fix it on a glass plate and absorb it with a suction cup Placed on a three-dimensional motion platfor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com