A kind of high-quality waveguide structure and preparation method

A waveguide structure, high-quality technology, used in optical waveguides, light guides, instruments, etc., can solve problems such as unrealizable, excellent optical performance, and achieve the effect of low transmission loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

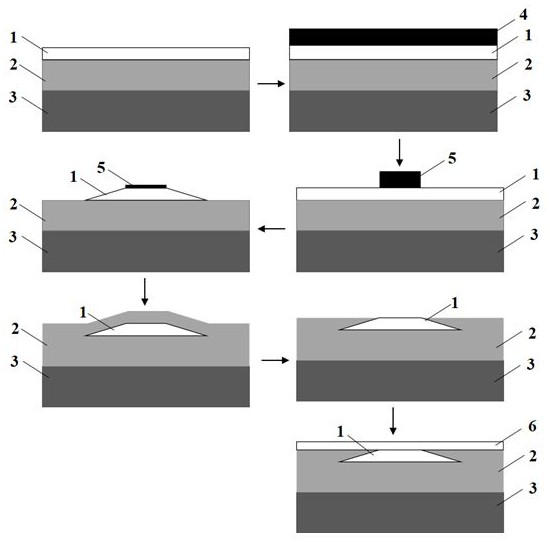

[0028] see figure 1 , the present invention utilizes femtosecond laser direct writing combined with chemical mechanical polishing technology and bonding lithium niobate thin film to prepare the method for waveguide, comprising the following steps:

[0029] (1) Prepare a lithium niobate wafer and coat its surface with a chrome film: take a 3-inch lithium niobate thin film wafer, the lithium niobate thin film wafer consists of a 300 nm thick lithium niobate thin film 1 and a 4.7 μm thick silicon dioxide layer 2 and a 0.5mm thick single crystal silicon substrate 3, and a 400nm thick chromium film layer 4 is plated on the surface of the lithium niobate film 1 by magnetron sputtering;

[0030] (2) Femtosecond laser direct writing chrome mask: Wipe the above lithium niobate thin film wafer after chrome coating 4 with acetone to keep the surface of the chrome film clean, and then fix it on the glass plate and absorb it with a suction cup It was placed on a three-dimensional motion p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com