Driving method, device of on-chip micro-nano object based on light force, and application

A driving method and driving device technology, applied in the field of light control, can solve the problems of easy pollution of the reaction field and poor controllability, and achieve the effects of improving the degree of accuracy, the degree of freedom, and the large control range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

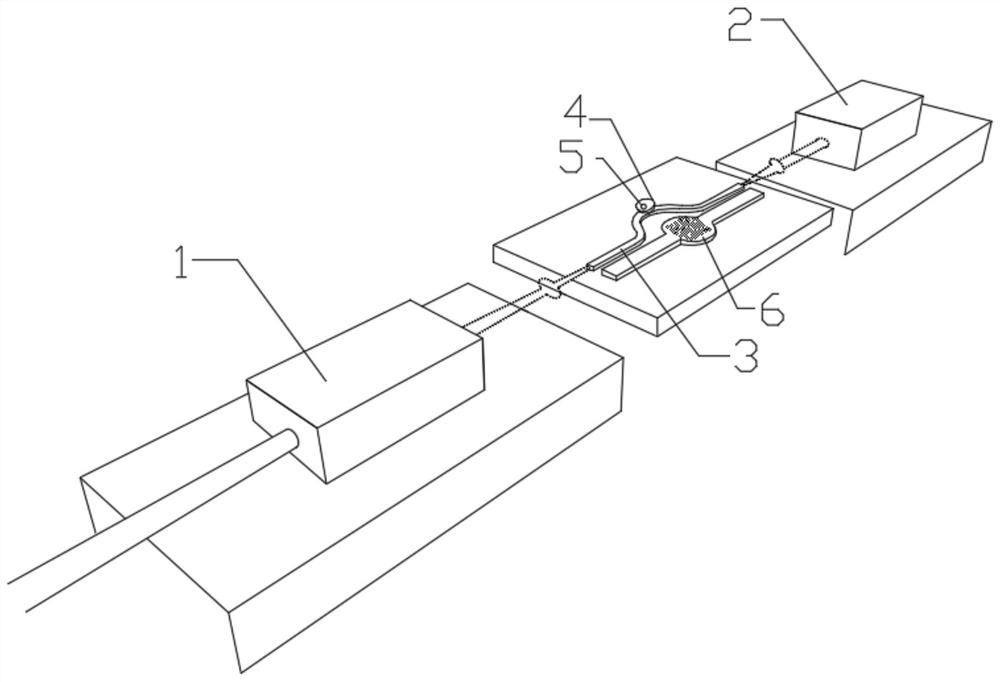

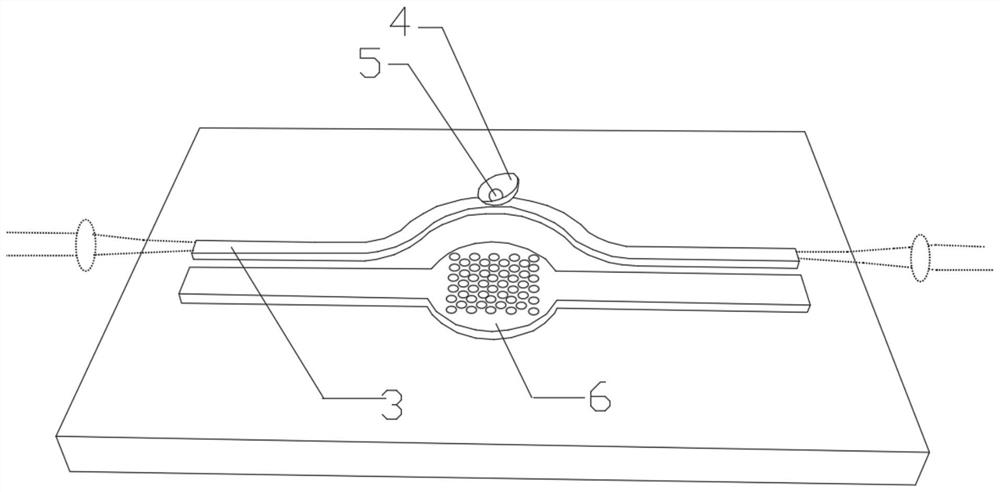

[0057] In the second aspect, this solution provides a method for preparing an on-chip micro-nano object driving device based on optical force, including the following steps: preparing an on-chip waveguide 3; preparing a micro-nano container 4 on the on-chip waveguide 3; using a probe to drive The micro-nano object 5 is transferred into the micro-nano container 4; the laser is coupled to the on-chip waveguide 3.

[0058] In the preparation scheme, the on-chip waveguide 3 can be prepared by using micro-nano processing and etching technology, and the micro-nano container 4 can be prepared on the on-chip waveguide 3 by using the micro-nano processing method and focused ion beam technology. The driven micro-nano object 5 is transferred into the micro-nano container 4. If the driven micro-nano object 5 is on the nanoscale, it can be transferred by using the micro-nano object 5 of the manipulator in the electron microscope.

[0059] In the third aspect, this solution provides an opti...

Embodiment 1

[0079] Embodiment 1: Translational drive of on-chip micro-nano objects based on optical force:

[0080] Place the object to be transported in the micro-nano container, fix the single pulse energy of the pulse laser 1 at 0.1-1 nanojoule at the initial stage, slowly increase the repetition frequency of the pulse light, so that the micro-nano container moves on the on-chip waveguide 3, wherein The initial position of point A, point B is the position corresponding to the movement time t1, and point C is the position corresponding to the movement time 10t1. Here, the repetition rate of the pulsed laser 1 can also be kept fixed, and the energy of a single pulse can be slowly increased. When the single pulse energy exceeds the threshold corresponding to driving the micro-nano container, the moving speed of the sample is proportional to the repetition frequency of the incident pulse laser and the single pulse energy.

[0081] Such as Figure 4 As shown, the micro-nano container move...

Embodiment 2

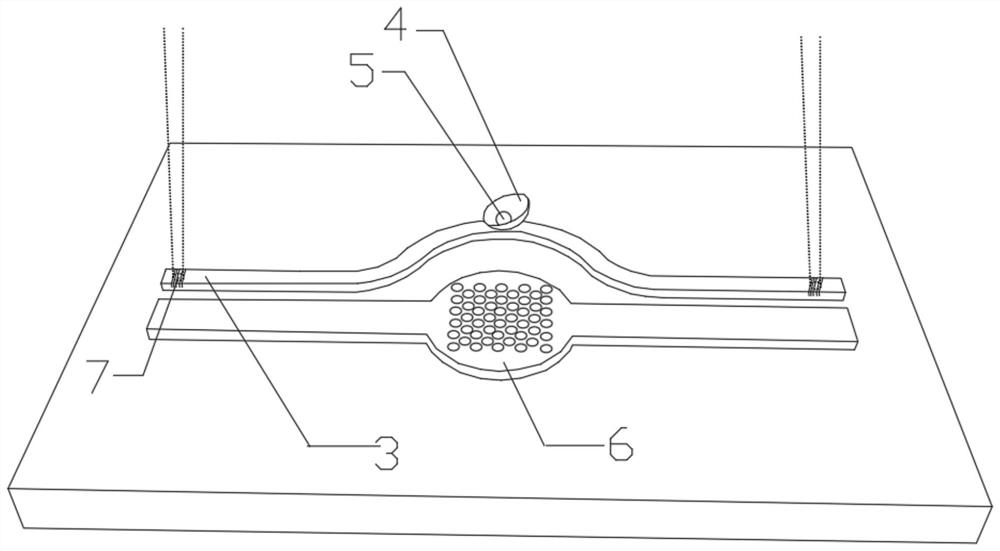

[0082] Embodiment 2: Swing drive of on-chip micro-nano objects based on optical force:

[0083] When the micro-nano-container 4 is transported to the target position of the waveguide, turn off the pulse laser and turn on the continuous laser. At this time, the translation of the sample stops and starts to swing. The frequency of the swing is the same as the modulation frequency of the continuous laser, and the amplitude of the swing is the same as that of the continuous laser. The power is proportional to the power, the greater the power, the greater the swing. Here, state C is the state before the continuous laser is turned on, and state D is the state after the continuous laser is turned on. When the swing speed is very high and exceeds the centrifugal force of the object being transported, the sample will break away from the micro-nano container, and the reached position can be precisely controlled by the swing speed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com