Bamboo leaf extract and preparation method and application thereof

A kind of bamboo leaf extract and bamboo leaf technology, applied in the field of bamboo leaf extract and its preparation, can solve the problem of residual beneficial ingredients and achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The compound enzyme of the present embodiment selects the compound of acid cellulase, pectinase, β-glucanase, acid xylanase, β-glucosidase, neutral protease specifically as shown in table 1:

[0028] Table 1 present embodiment composite enzyme preparation raw material formula

[0029]

[0030] The compound of phenylalanine, tyrosine, proline of the present embodiment, reducing sugar selects the compound of fructose and glucose, and specific formula is as shown in table 2:

[0031] The raw material formula of table 2 present embodiment amino acid and reducing sugar

[0032] name Phenylalanine Tyrosine proline fructose glucose Mass / g 2.5 4 1.5 5.6 6.6

[0033] The specific preparation method is:

[0034] S1: Take bamboo leaves after cleaning and drying, weigh 50g of dried bamboo leaves, and pulverize them to obtain bamboo leaf powder for later use;

[0035] Weigh 20g of deionized water in a beaker, according to the formula in Table 1...

Embodiment 2

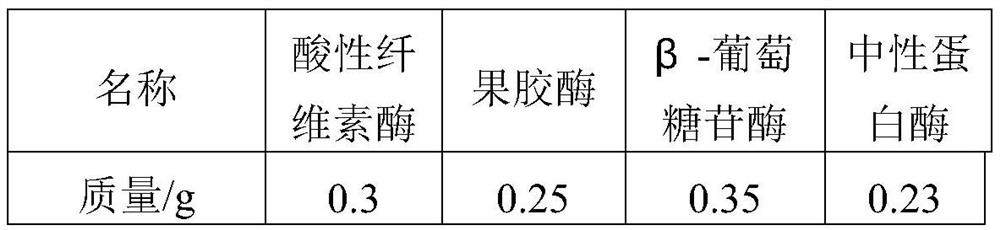

[0043] The compound enzyme of the present embodiment selects the compound of acid cellulase, pectinase, β-glucosidase, neutral protease specifically as shown in table 3:

[0044] Table 3 present embodiment composite enzyme preparation raw material formula

[0045]

[0046] The compound of phenylalanine and tyrosine in this embodiment, the reducing sugar is selected from the compound of fructose and glucose, and the specific formula is as shown in table 4:

[0047] The raw material formula of table 4 present embodiment amino acid and reducing sugar

[0048] name Phenylalanine Tyrosine fructose glucose Mass / g 3.5 4.5 5.6 6.6

[0049] The specific preparation method is:

[0050] S1: Take bamboo leaves after cleaning and drying, weigh 50g of dried bamboo leaves, and pulverize them to obtain bamboo leaf powder for later use;

[0051] Weigh 20g of deionized water with a beaker, according to the formula in Table 3, respectively weigh the enzyme pre...

Embodiment 3

[0059] The compound enzyme of the present embodiment selects the compound of acid cellulase, pectinase, β-glucanase, acid xylanase, β-glucosidase, neutral protease specifically as shown in table 5:

[0060] Table 5 present embodiment composite enzyme preparation raw material formula

[0061]

[0062] The compound of tyrosine and proline of the present embodiment, glucose is selected as the reducing sugar, and the specific formula is as shown in table 6:

[0063] The raw material formula of table 6 present embodiment amino acid and reducing sugar

[0064] name Tyrosine proline glucose Mass / g 5 3.5 12.6

[0065] The specific preparation method is:

[0066] S1: Take bamboo leaves after cleaning and drying, weigh 50g of dried bamboo leaves, and pulverize them to obtain bamboo leaf powder for later use;

[0067] Weigh 20g of deionized water in a beaker, according to the formula in Table 5, respectively weigh the enzyme preparations into deionized wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com