Electrochemical system with near-zero energy consumption display device, preparation method and display method

A technology of a display device and a display method, which is applied in the field of electrochemical systems, can solve problems such as limited battery energy, limited color switching, and limited resolution diffraction limit, and achieve ultra-high resolution, realize self-supply, and reduce energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] In another specific embodiment, the present invention provides a kind of preparation method of above-mentioned electrochemical system, and described preparation method specifically comprises the following steps:

[0056] Evaporate and / or deposit a conductive layer 2 on the surface of the first pole piece 1 of the electrochemical system, then evaporate and / or deposit a dielectric layer 3 on the surface of the conductive layer 2, and use electron beam exposure and focus ions on the dielectric layer 3 The electrochemical system is prepared by opening a group of through holes by beam or photolithography, and assembling with the second pole piece and electrolyte.

[0057] Exemplarily, an assembly method of the above-mentioned electrochemical system is provided, the assembly method comprising:

[0058] In the process of assembling the display device, the negative pole piece is used as one side of the battery, and the conductive layer is drawn out with conductive copper as the...

Embodiment 1

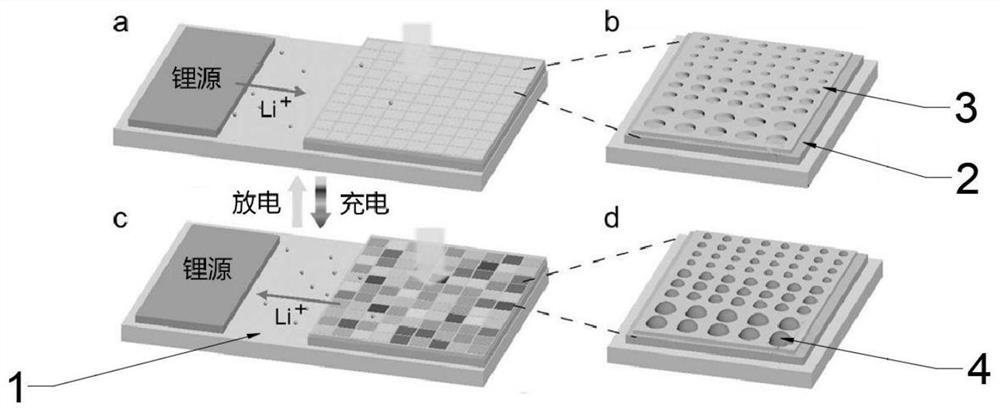

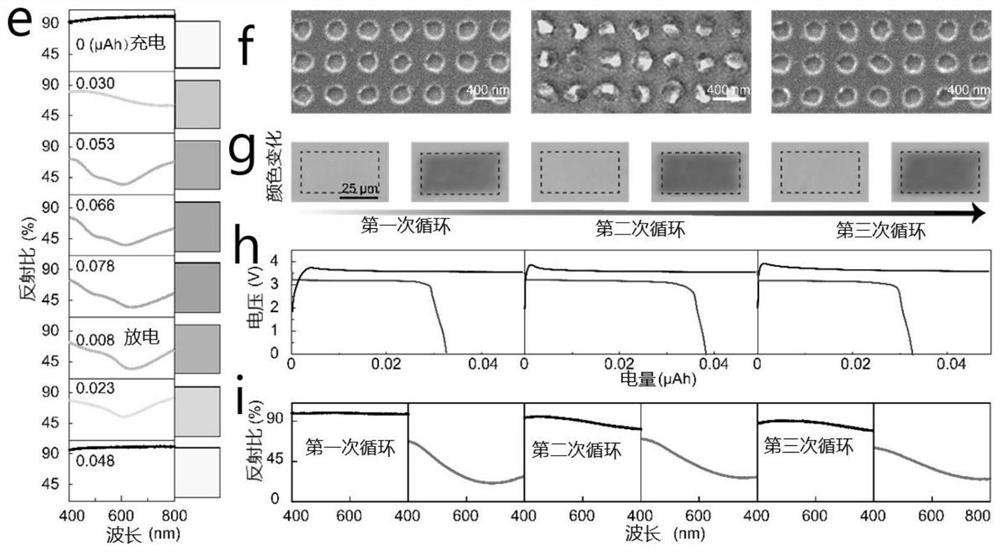

[0062] This embodiment provides an electrochemical system, the type of the electrochemical system is a lithium metal battery, such as figure 1 As shown, a conductive layer 2 and a dielectric layer 3 are sequentially stacked on the negative electrode sheet of the electrochemical system, and a group of rectangular through holes are opened on the dielectric layer 3 .

[0063] Further, the diameter of the through holes in the through hole group is 200 nm, and the distance between adjacent through holes is 400 nm.

[0064] Further, the thickness of the conductive layer 2 is 100 nm, and the material is tungsten. The thickness of the dielectric layer 3 is 50nm, and the material is magnesium fluoride.

[0065] This embodiment also provides a preparation method of the above-mentioned electrochemical system, and the preparation method specifically includes the following steps:

[0066]Evaporate a conductive layer 2 on the surface of the first pole piece 1 of the electrochemical system...

Embodiment 2

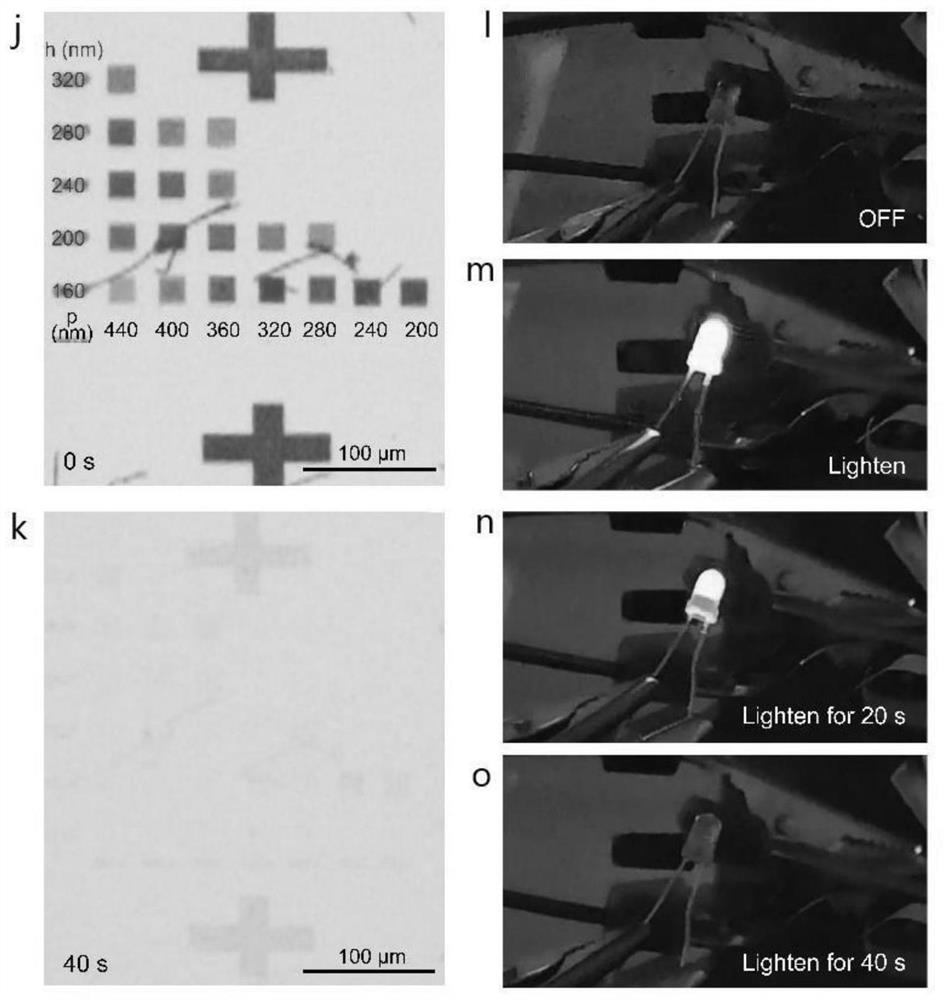

[0071] This embodiment provides an electrochemical system, which is a type of lithium metal battery. The surface of the negative electrode sheet of the electrochemical system is stacked with a conductive layer 2 and a dielectric layer 3 sequentially from bottom to top, and four groups of A rectangular through-hole group; divided into a first through-hole group, a second through-hole group, a third through-hole group and a fourth through-hole group, wherein the first through-hole group and the second through-hole group are arranged side by side, and the third through-hole group The through hole group and the fourth through hole group are arranged side by side.

[0072] Further, the diameters of the through holes in the first through hole group and the second through hole group are both 200 nm, and the distance between adjacent through holes is 360 nm. The diameters of the through holes in the third through hole group and the fourth through hole group are both 240 nm, and the di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com