Medium-voltage aluminum alloy overhead insulated cable and preparation method thereof

An aerial insulated cable and aluminum alloy technology, which is applied in the direction of cable/conductor manufacturing, power cable, power cable with shielding layer/conductive layer, etc., can solve the problem of low strength or weather resistance of the insulation layer, low adhesion, and auxiliary materials. Waste and other problems, achieve good insulation effect and weather resistance, improve surface smoothness, and improve electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

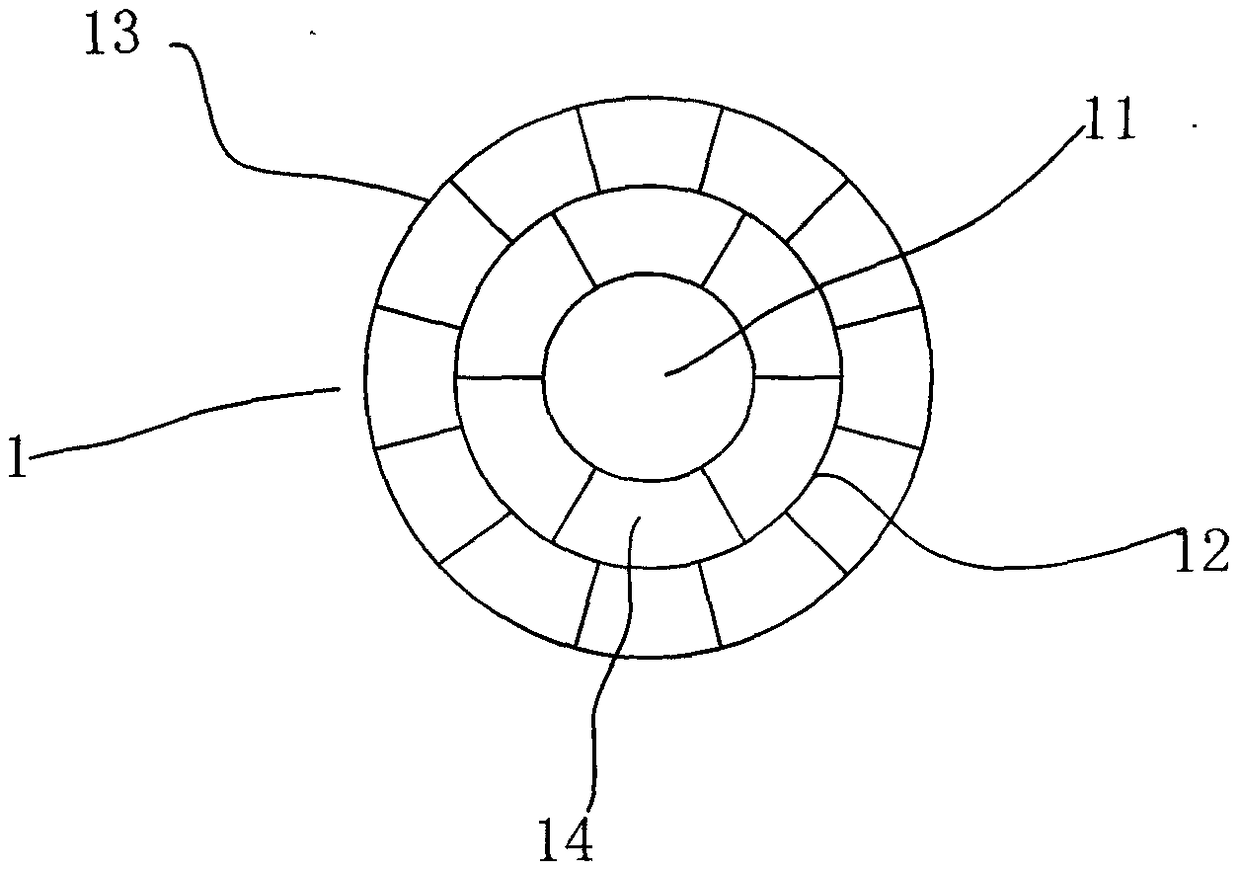

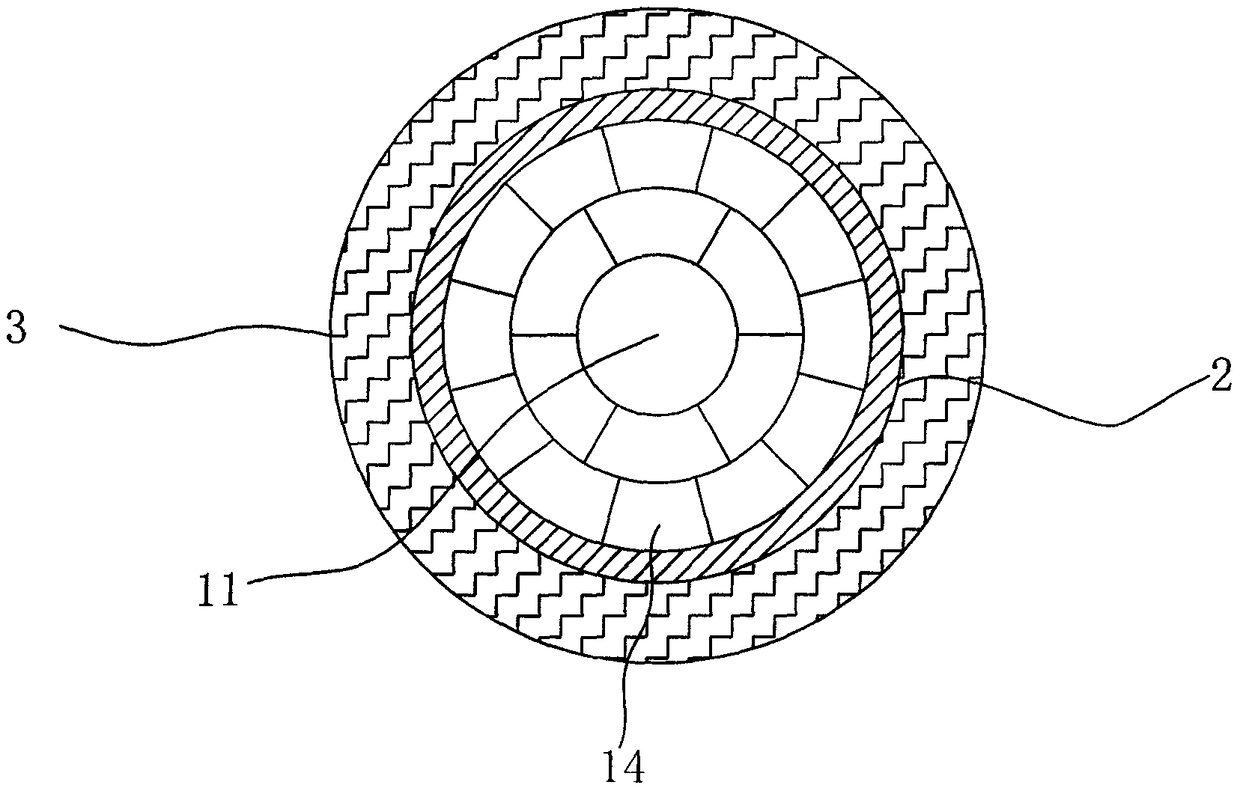

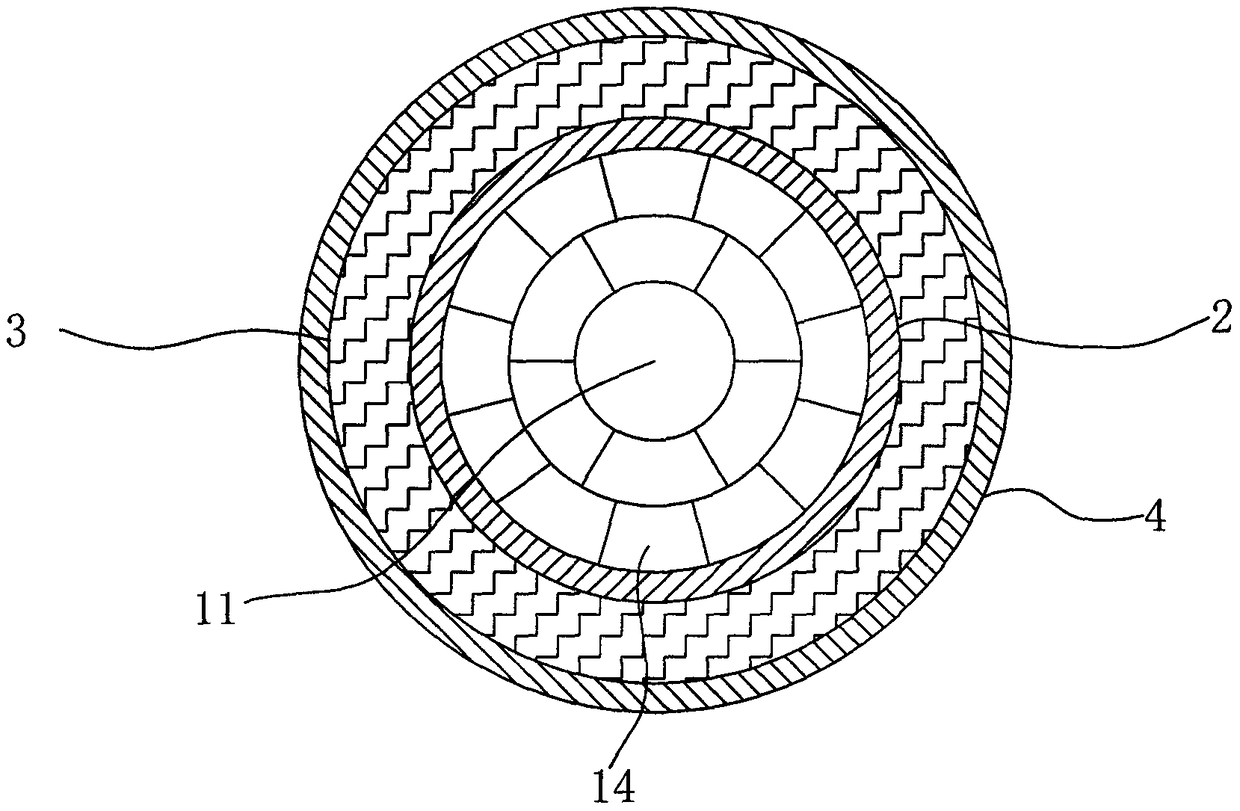

[0028] like figure 1 , 2 As shown, a medium-voltage aluminum alloy aerial insulated cable includes a wire core, and the wire core includes a conductor 1, and the conductor includes a circular single-core layer 11 arranged in the center, and at least two layers arranged in sequence outside the circular single-core layer 11 Compression layer, preferably two layers, including the first compression layer 12, the second compression layer 13, each compression layer includes several twisted shaped wire conductors 14, preferably trapezoidal shaped wire conductors, the number is 6, The profiled wire conductors of two adjacent tight layers are staggered from each other, the conductors are covered with an inner shielding layer 2, and the inner shielding layer is covered with an insulating layer 3. The material of the inner shielding layer is a cross-linked conductor shielding material, and the insulating layer The material is weather-resistant overhead insulation material. Preferably, ...

Embodiment 2

[0036] The difference from Example 1 is:

[0037] A medium-voltage aluminum alloy overhead insulated cable, the crosslinked conductor shielding material is prepared from the following components: polyethylene 90kg, carbon black 30kg, graphene fiber 12.5kg, nano-scale kaolin 9kg, crosslinking agent DCP 3.5kg, Silane coupling agent A-1720.35kg, antioxidant DNP 0.3kg. The weather-resistant overhead insulating material is prepared from the following components: cross-linked polyethylene 90kg, ethylene-vinyl acetate copolymer 50kg, ABS resin 65kg, crosslinking agent PDM 0.5kg, adhesive poly alum modified epoxy resin 0.35 kg, nano kaolin 7.5kg, oil retardant 6.5kg, silane coupling agent A-172 0.35kg, dispersant 0.45kg, antioxidant DNP 0.35kg, weather resistance agent UV-9 0.35kg.

[0038] A method for preparing a medium-voltage aluminum alloy overhead insulated cable. In the step (2) drying and dehumidification: the shielding particles and insulating particles are respectively drie...

Embodiment 3

[0040] The difference from Example 1 is:

[0041] A medium-voltage aluminum alloy overhead insulated cable, the crosslinked conductor shielding material is prepared from the following components: polyethylene 100kg, carbon black 40kg, graphene fiber 15kg, nano-scale kaolin 10kg, crosslinking agent DCP 5kg, silane coupling Agent A-1720.5kg, antioxidant DNP 0.4kg. The weather-resistant overhead insulating material is prepared from the following components: cross-linked polyethylene 100kg, ethylene-vinyl acetate copolymer 60kg, ABS resin 75kg, crosslinking agent PDM 0.6kg, adhesive poly alum modified epoxy resin 0.5 kg, nano kaolin 9kg, oil retardant 8kg, silane coupling agent A-172 0.5kg, dispersant 0.6kg, antioxidant DNP 0.5kg, weather resistance agent UV-9 0.5kg.

[0042] A method for preparing a medium-voltage aluminum alloy overhead insulated cable. In step (2) drying and dehumidification: the shielding particles and insulating particles are respectively dried and dehumidif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com