Bipolar membrane-assisted ion rectification method for preparing battery-grade lithium product from salt lake brine in one step

A salt lake brine and bipolar membrane technology, applied in semi-permeable membrane separation, chemical instruments and methods, membranes, etc., can solve unsatisfactory screening performance, limit target ion separation efficiency, and continuous operation characteristics cannot be effectively reflected, etc. problems, to achieve the effect of reducing the requirements of its own characteristics, reducing the cost of preparation and research and development, and improving selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

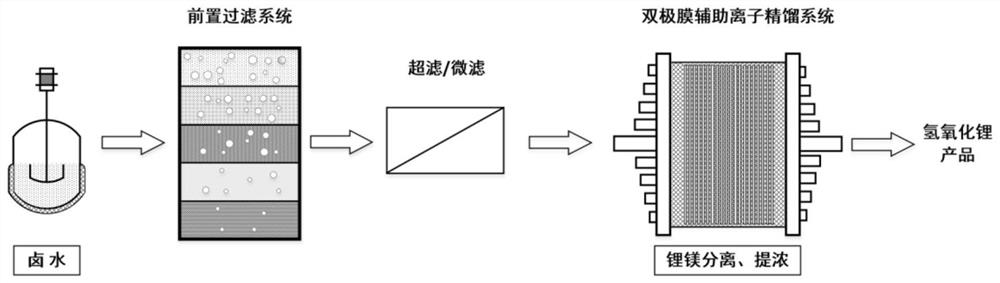

[0045] In this example, the above-mentioned ion cooperative rectification system is used to process the actual salt lake old brine. At the initial stage: the main ion components and compositions of the old brine are shown in Table 1. Before passing through the ion rectification system, the salt lake brine undergoes multi-pond evaporation and multi-step crystallization , Causticization precipitation, ultrafiltration, microfiltration, activated carbon adsorption process, remove sodium, potassium, boron and other impurity ions, as well as suspended particles of different particle sizes in the solution.

[0046] Table 1 Main components of salt lake brine

[0047]

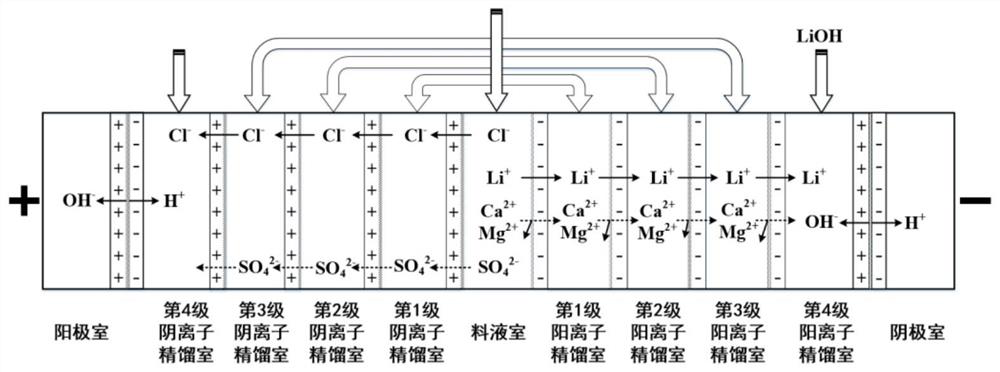

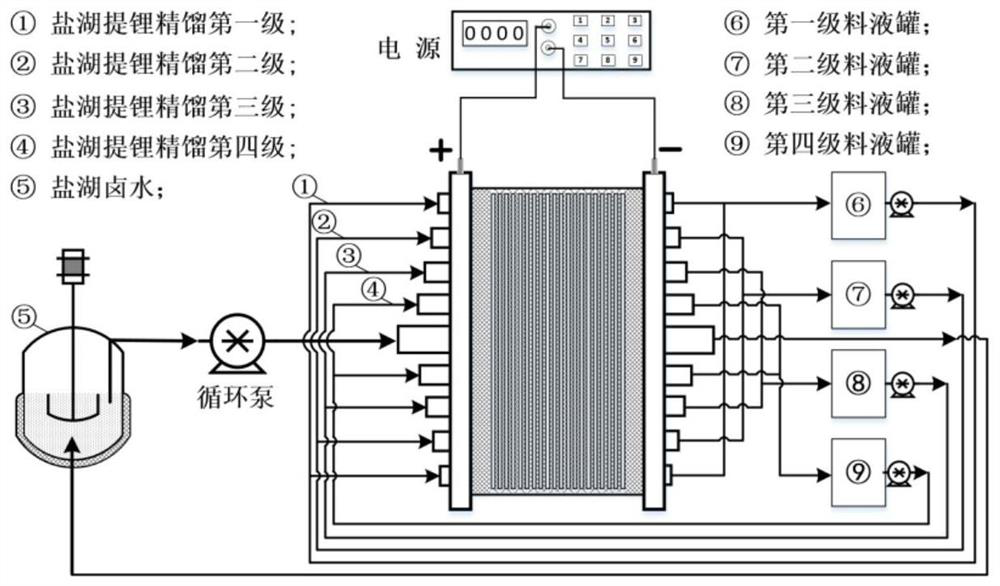

[0048] The ion synergistic rectification system adopted is a four-stage ion synergistic rectification system, and the number of ion rectification units is 1; the first-stage anion rectification chamber is connected with the first-stage cation rectification chamber, and the circulation flow is driven by a solution-driven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com