Environment-friendly special-effect multifunctional bactericide and production method thereof

A production method and multi-functional technology, applied in the directions of bactericides, biocides, mixing methods, etc., can solve the problems of unevenness, decreased bactericidal effect, material splashing and agglomeration mixing, etc. Efficient and uniform heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

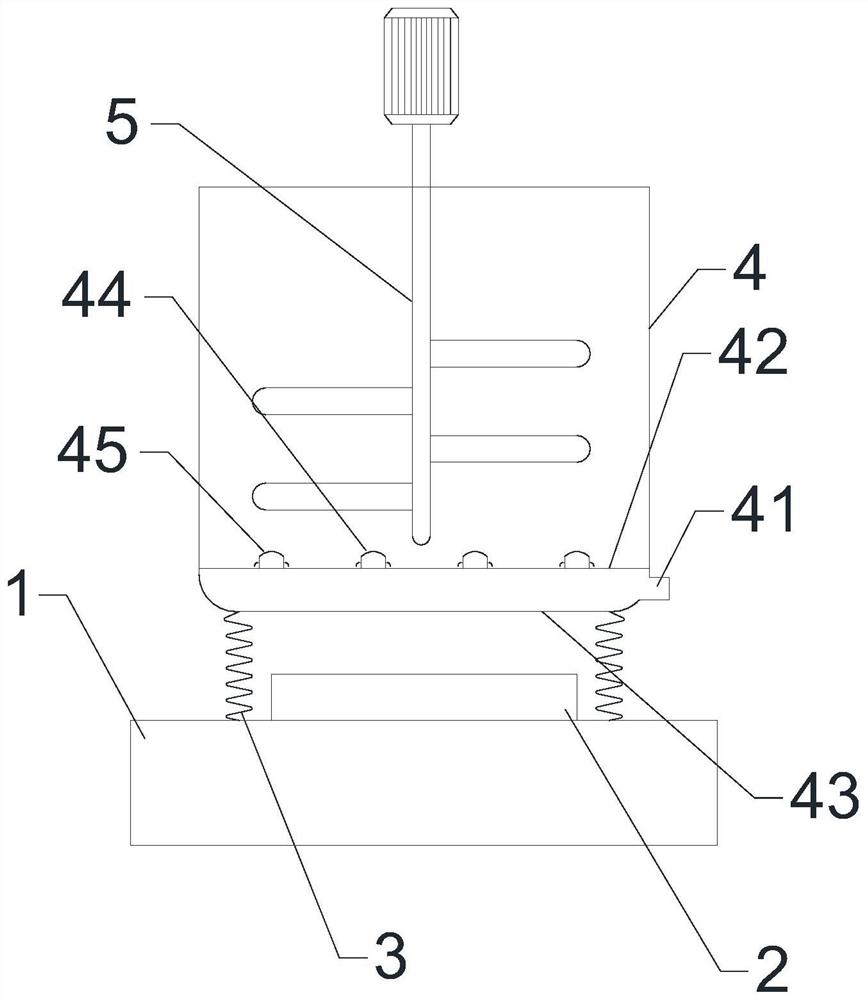

[0037] The invention relates to a production method of an environment-friendly special-effect multifunctional fungicide, which comprises adding raw materials except water into a mixer, and slowly adding water for stirring and mixing. The mixer includes a support base 1, a heating chassis 2, a lifting spring 3, a stirring tank 4, and a stirring paddle 5. The heating chassis 2 is arranged on the support base 1, and several lifting springs 3 are arranged on the outer periphery of the heating chassis 2. The height of the lifting springs 3 is higher than the height of the heating chassis 2, and the two ends of the lifting spring 3 are respectively fixed on the support base 1 and the bottom of the stirring tank 4; The driving device of the stirring paddle 5 is fixed above the stirring tank 4, and the stirring paddle 5 extends into the stirring tank 4.

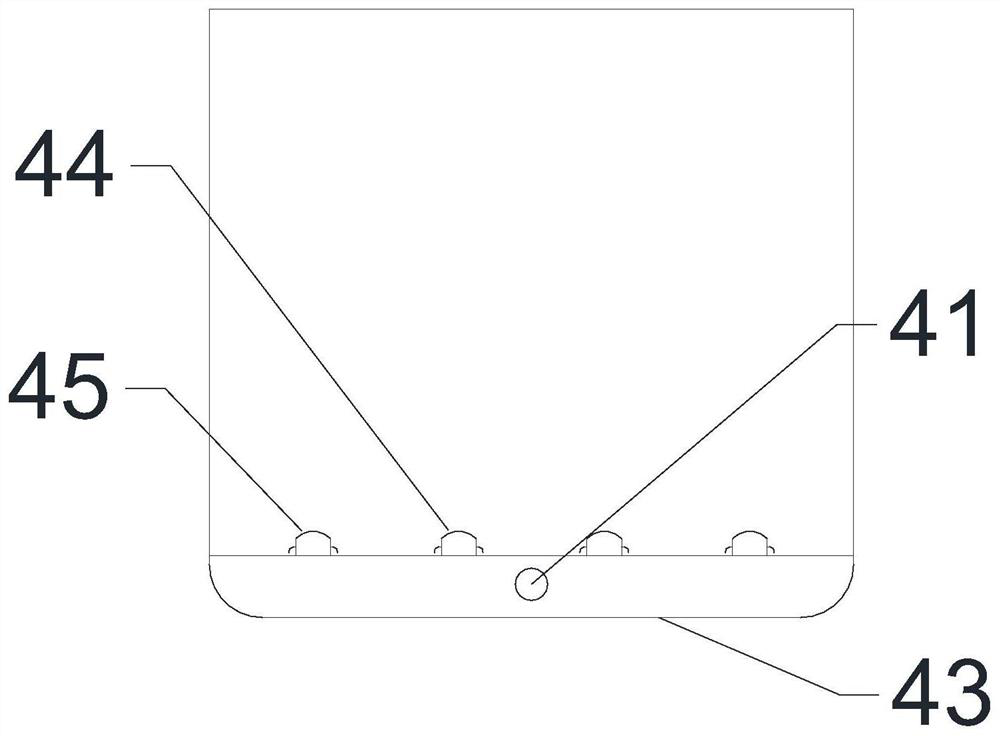

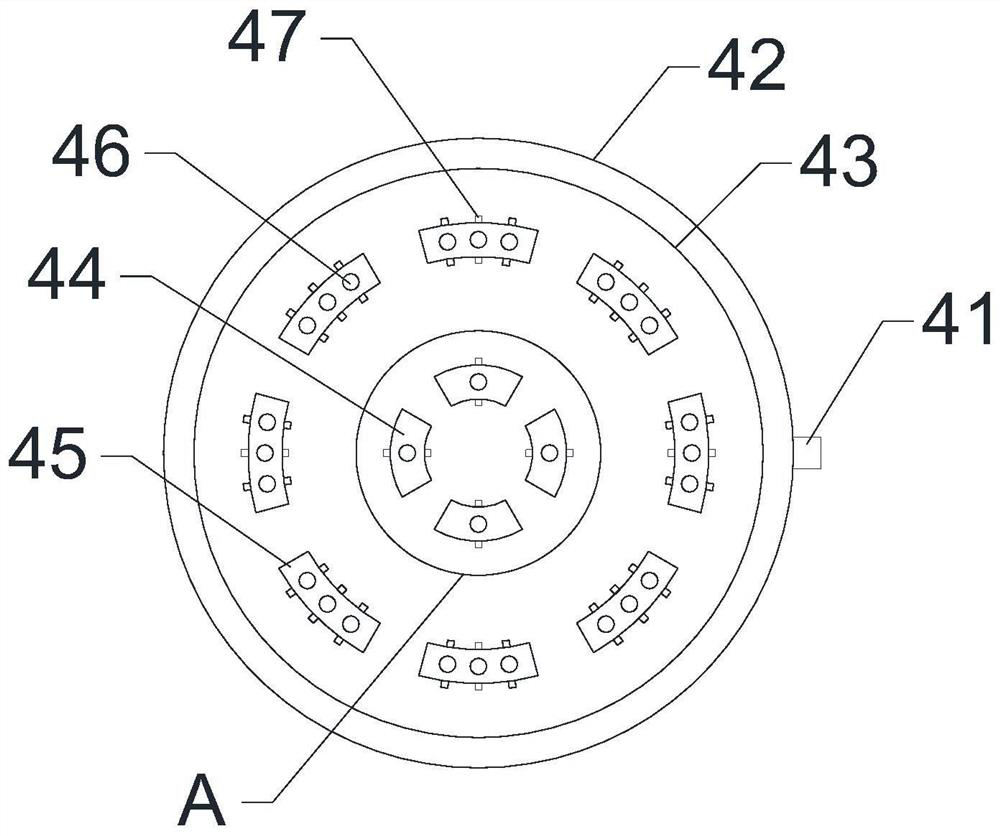

[0038] The stirring tank 4 includes a water inlet 41, an upper tank bottom 42, a lower tank bottom 43, a plurality of first arc-sha...

Embodiment 2

[0043] The difference between this embodiment and Embodiment 1 is that the water wheel mounting plate 47 includes a symmetrically arranged mounting vertical plate 471 and a semi-surrounding top plate 472, the mounting vertical plate 471 is fixed on both sides of the water outlet, and the semi-surrounding top plate 472 is connected to the vertical mounting plate 472. The top of the plate 471 is fixed to realize the semi-enclosed installation of the water wheel 48. The water wheel 48 includes a rotating shaft 481 , a mounting sleeve 482 , a bent blade 483 and a non-return arc plate 484 . The rotating shaft 481 is movably installed in the middle of the vertical plate 471 . The water wheel 48 rotates in a direction away from the water outlet pipe 46 , and the bent blade 483 is fixed on the outer periphery of the installation sleeve 482 in a clockwise or counterclockwise direction. The non-return arc-shaped plate 484 is movably installed on the back side of the bent blade 483 , an...

Embodiment 3

[0045] The difference between this embodiment and Embodiment 2 is that the non-return arc plate 484 is movably hinged on the hinge seat 485 through the hinge shaft 486, and the hinge seat 485 is fixed on the back side middle of the bent blade 483, and the non-return arc plate 484 and the bending direction of the bending blade 483 are opposite.

[0046] In the process of adding water or stirring, the mixed liquid in the mixing tank 4 will tend to flow back into the arc-shaped water cavity of the first arc-shaped U-shaped pinch plate 44 and the second arc-shaped U-shaped pinch plate 45 due to the liquid pressure. The backflowing liquid provides force to push the water wheel 48 to reversely rotate in the direction close to the water outlet pipe 46. At this time, the back of the bent blade 483 near the inner side of the water outlet pipe 46 is pressed down due to gravity and centrifugal force. Tightly bend the back side of the blade 483, if the reverse rotation of the water wheel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com