Regenerated catalyst, regeneration method and application of catalyst, and residual oil hydrogenation method

A technology for regenerating catalysts and to-be-generated catalysts, which can be used in catalyst regeneration/reactivation, catalyst activation/preparation, chemical elements of heterogeneous catalysts, etc., and can solve the problem of inability to use residue hydrodesulfurization and carbon residue removal catalyst regeneration, etc. To achieve the effect of good activity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0039] According to a preferred embodiment of the present invention, the regeneration method of described catalyst comprises the steps:

[0040] Under pretreatment conditions, reacting the spent catalyst with a first oxygen-containing gas; then under regeneration conditions, contacting the pretreated spent catalyst with an oxygen-containing gas;

[0041] The pretreatment conditions include: the temperature is 300-450°C, preferably 320-400°C, the time is 1-8 hours, preferably 3-5 hours, and the oxygen content in the first oxygen-containing gas is not higher than 10% by weight , preferably 2-10% by weight;

[0042] The regeneration conditions include: the regeneration temperature is 530-750°C, and the oxygen content in the oxygen-containing gas is not less than 20% by weight;

[0043] The spent catalyst includes carbon, a support, and a hydrogenation active metal component supported on the support, and the hydrogenation active metal component contains at least one VIB group met...

specific Embodiment approach

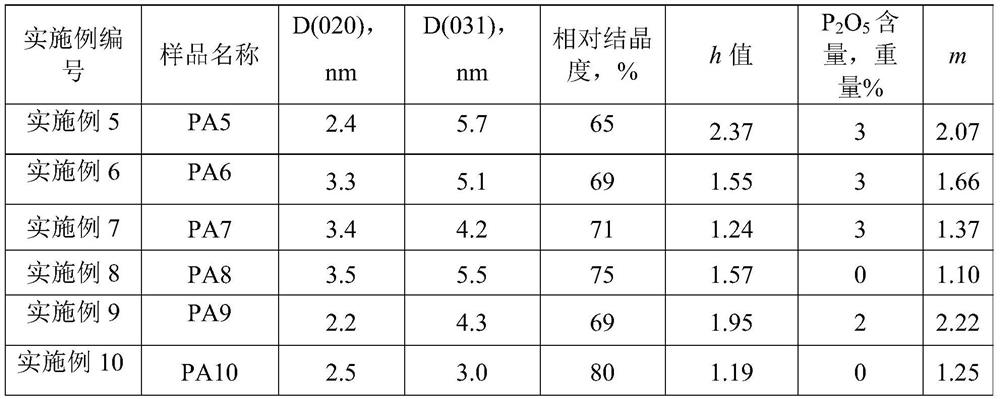

[0071] According to a specific embodiment of the present invention, step (1) includes: contacting an inorganic aluminum-containing compound solution, a phosphorus-containing compound, a grain growth regulator, and an acid or a base for precipitation reaction, or, bringing an organic aluminum-containing compound, a The phosphorus compound, the grain growth regulator and the water undergo a hydrolysis reaction; the pH of the precipitation reaction or the hydrolysis reaction is controlled to be 4-7.

[0072] According to a preferred embodiment of the present invention, the precipitation reaction or the hydrolysis reaction in step (1) is carried out in the presence of a grain growth regulator and a phosphorus-containing compound at a pH of 4-6.5. Making the precipitation reaction or hydrolysis reaction proceed at the above preferred pH is more conducive to improving the hydrogenation activity of the prepared hydrogenation catalyst in heavy oil hydrogenation.

[0073] In the presen...

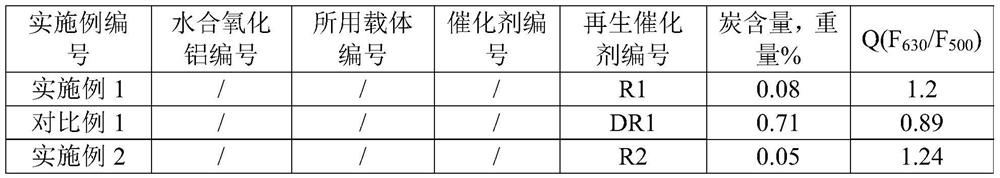

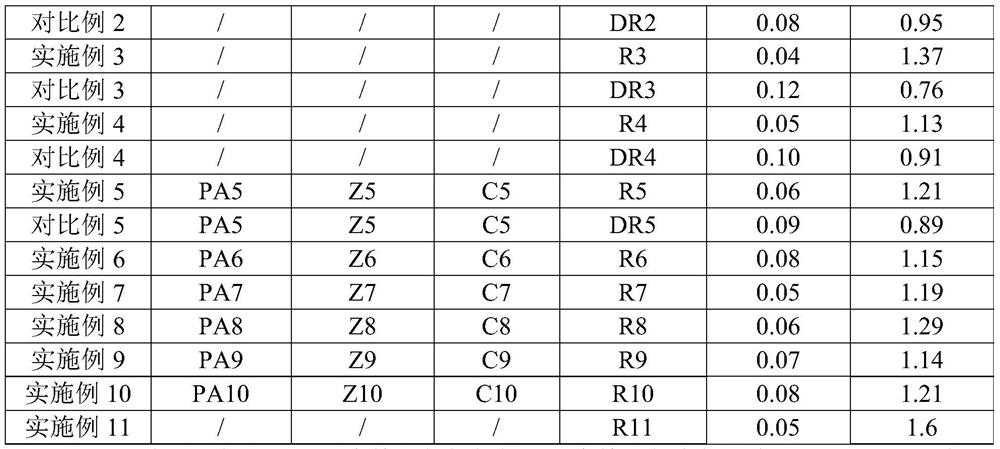

Embodiment 1

[0128] This example is used to illustrate the regenerated catalyst and its regeneration method of the present invention.

[0129] Get 1000 grams of raw residue oil hydrogenation catalyst A (the corresponding fresh catalyst is C1) and place it in a tube furnace, and heat it up to 350° C. in flowing air at 3° C. / min. The ratio of oil hydrogenation catalyst A is 4 liters / gram, keep the oxygen content in the air atmosphere at 5wt%, and carry out pretreatment at a constant temperature for 2 hours; then heat up to 600°C at 3°C / min, and control the oxygen content in the air atmosphere to 40wt% , the air flow rate and the ratio of the hydrogenation catalyst A to be raw residue oil are 4 liters / gram, constant temperature for 3h, to obtain the regenerated catalyst R1, and the Q value of R1 measured by ultraviolet-visible light spectroscopy is shown in Table 1. The carbon content of R1 is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com