Core filling system for manufacturing ardealite whiskers

A phosphogypsum whisker and core-filling technology, which is applied in the field of insulating rubber and high-insulation core-filling equipment, can solve the problems of high production cost, increased transportation cost, and loss of intermediate products, so as to speed up the vulcanization speed, The effect of accelerating the decomposition rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Next, the technical solutions in the embodiments of the present invention will be described in connection with the drawings of the embodiments of the present invention, and it is understood that the described embodiments are merely the embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art are in the range of the present invention without making creative labor premise.

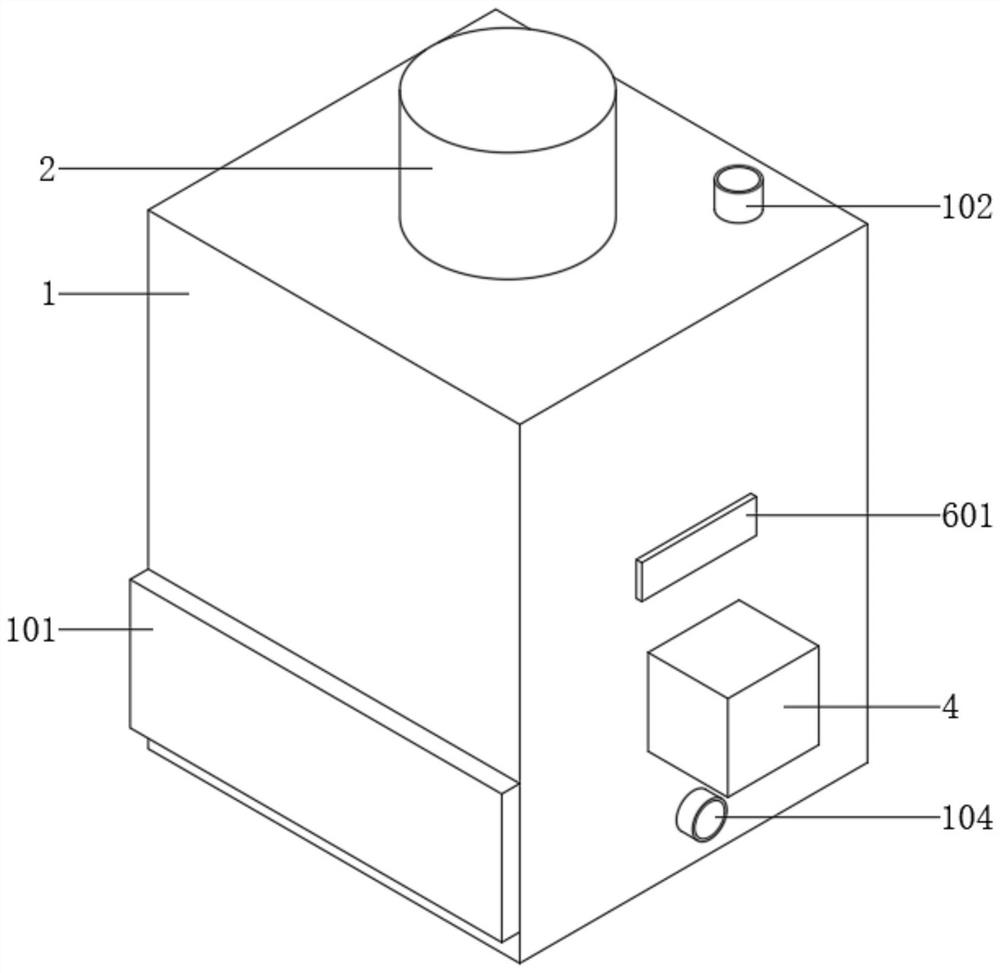

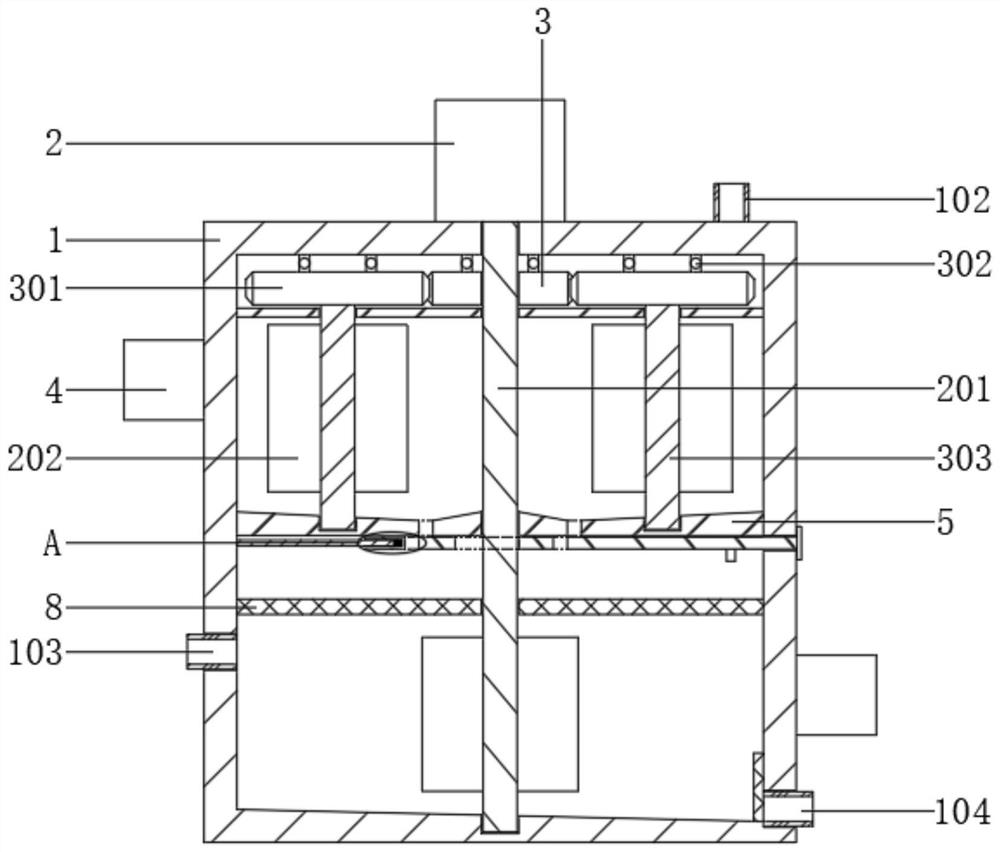

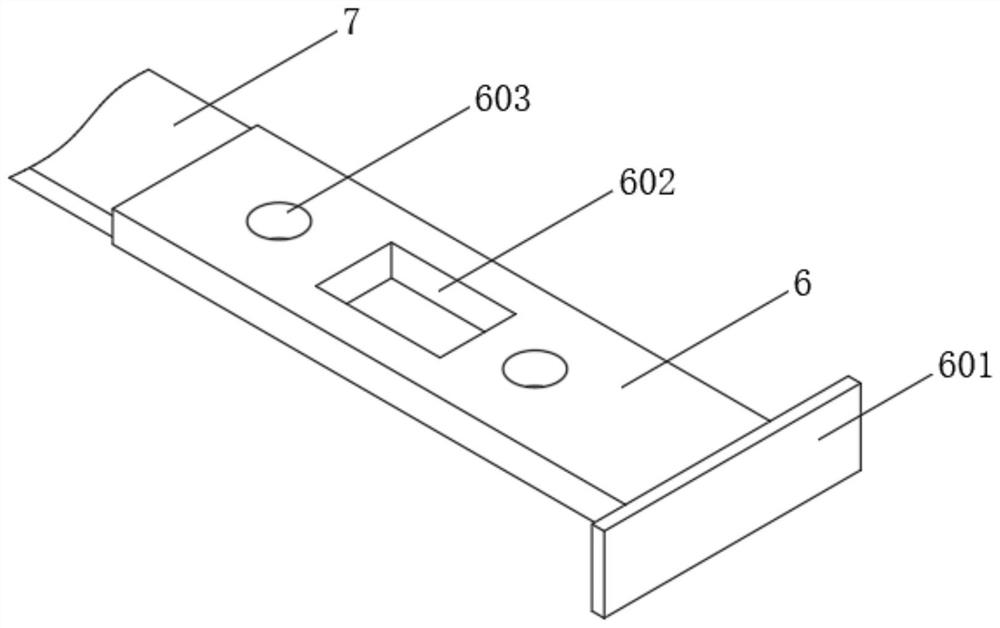

[0031] See Figure 5-6 As shown, a high insulating filling compound apparatus for making phosphite whiskers is calculated according to the weight of the weight, including:

[0032] 90 ~ 120 standard glue, 1 ~ 2 sulfur, 7 ~ 9 nano-zinc oxide, 10 ~ 15 sulfur 2 morphorpholine, 0.3 ~ 0.8 serial salicylic acid, 18 ~ 22 replenishment of strong carbon black, 20 To 25 parts of insulating oil, 13 to 18 parts of oil, 8 ~ 12 servantic acid dibutyl, 100 to 150 parts of phosphite, 1000 ~ 1500...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com