Polylactic acid-based 3D printing composite material capable of continuously emitting light, and preparation method thereof

A 3D printing and composite material technology, which is applied in the field of polylactic acid-based 3D printing composite materials and its preparation, can solve the problems of poor dispersion of polylactic acid, easy moisture absorption and agglomeration, and achieve the effect of improving mechanical properties and expanding application fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

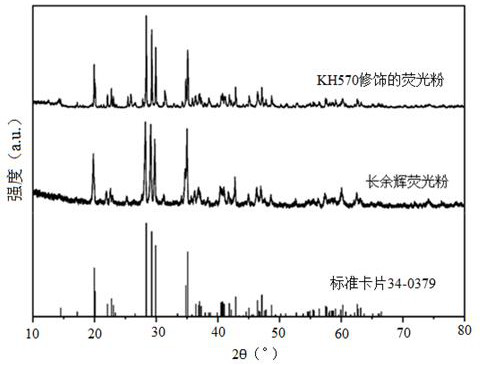

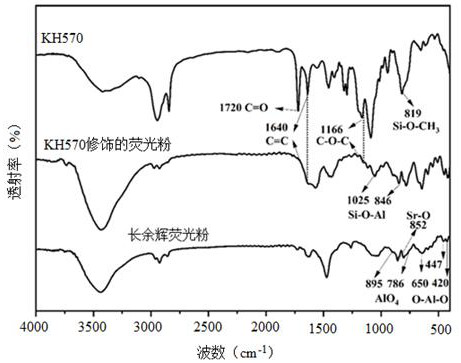

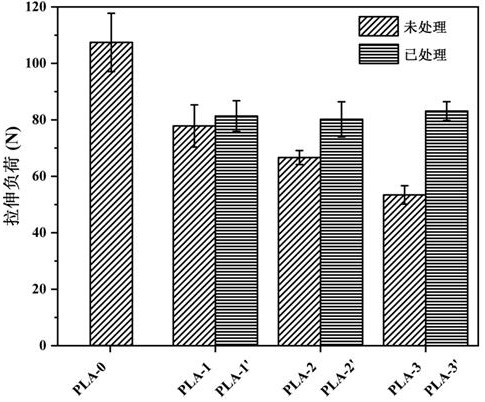

[0027] Using strontium carbonate, aluminum oxide, boric acid, europium oxide and dysprosium oxide as raw materials, the long afterglow phosphor (SrAl 2 o 4 : Eu 2+ , Dy 3+ ); according to mass percentage, respectively take 1% long-lasting phosphor, 1% KH570 and 98% polylactic acid; add 0.1g long-lasting phosphor to 1mL ethanol, add long-lasting phosphor to ethanol, After ultrasonic oscillation for 20min, add the KH570 taken, adjust the pH=4 with acetic acid, at 50°C and N 2 Reflux under atmosphere for 10h (speed 250r / min), cool to room temperature, centrifuge, filter and wash with ammonia water and ethanol several times to remove acetic acid and unreacted KH570, dry in a vacuum oven at 80°C to constant weight, grind, The phosphor powder modified by KH570 was obtained; the obtained polylactic acid was placed in a vacuum oven, dried at 60°C for 7 hours, and then blended with the phosphor powder modified by KH570 to obtain a 3D printing blend with sustainable luminescence; Th...

Embodiment 2

[0032] Using strontium carbonate, aluminum oxide, boric acid, europium oxide and dysprosium oxide as raw materials, the long afterglow phosphor (SrAl 2 o 4 : Eu 2+ , Dy 3+ ); according to mass percentage, respectively take 2% long-lasting phosphor, 1.6% KH570 and 96.4% polylactic acid, add 1g long-lasting phosphor to 1mL ethanol, add long-lasting phosphor to ethanol, and ultrasonically After shaking for 30min, add the taken KH570, adjust the pH to 5 with acetic acid, at 60°C and N 2 Reflux under atmosphere for 15h (speed 350r / min), cool to room temperature, centrifuge, filter and wash with ammonia water and ethanol several times to remove acetic acid and unreacted KH570, dry in a vacuum oven at 90°C to constant weight, grind, Phosphor powder modified by KH570 was obtained; polylactic acid was dried in a vacuum oven at 60°C for 5 hours, and blended with phosphor powder modified by KH570 to obtain a sustainable luminous 3D printing blend; the blend was loaded into a 3D printi...

Embodiment 3

[0037] Using strontium carbonate, aluminum oxide, boric acid, europium oxide and dysprosium oxide as raw materials, the long afterglow phosphor (SrAl 2 o 4 : Eu 2+ , Dy 3+ ); according to the mass percentage, take 3% long-lasting phosphor, 0.1% KH570 and 96.9% polylactic acid; add 0.55g long-lasting phosphor to 1mL ethanol, add In ethanol, after ultrasonic oscillation for 10 min, add the obtained KH570, adjust pH = 6 with acetic acid, at 70 °C and N 2 Reflux under atmosphere for 24h (speed 500r / min), cool to room temperature, centrifuge, filter and wash with ammonia water and ethanol several times to remove acetic acid and unreacted KH570, dry in a vacuum oven at 85°C to constant weight, grind, Phosphor powder modified by KH570 was obtained; polylactic acid was dried in a vacuum oven at 60°C for 10 hours, and blended with phosphor powder modified by KH570 to obtain a 3D printing blend material with sustainable luminescence; the blend material was loaded into a 3D printing e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com