Conductive silica gel and preparation method thereof and a silica gel key

A technology of conductive silica gel and silicone rubber, which is applied in the field of silica gel products, can solve problems such as the decrease of the surface conductivity of conductive silica gel, poor dispersion performance of conductive fillers, and poor conductivity of conductive silica gel, so as to achieve moderate contact area and improve thermal decomposition. The effect of high initial temperature and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0044] A modified conductive filler is carried out according to the following steps:

[0045] Silicon nitride modification treatment:

[0046] Weigh 40 kg of silicon nitride powder, put the silicon nitride powder into 300 L of anhydrous ethanol solution, carry out ultrasonic dispersion, the ultrasonic frequency is 40 kHz, and the ultrasonic time is 1 h to obtain a silicon nitride suspension;

[0047] Under the condition that the silicon nitride suspension is stirred at a rate of 300r / min, add deionized water (the volume ratio of deionized water and absolute ethanol is 1:10), and continue to add 2kg γ-aminopropyltriethyl Silane, prepared into reaction solution 1;

[0048] As soon as the temperature of the reaction solution was raised to 55°C, the reaction was kept for 6 hours, filtered, and the obtained solid was washed with deionized water for 3 times, and then freeze-dried to obtain modified silicon nitride.

[0049] Filler preparation:

[0050] The modified silicon nitrid...

preparation example 2-5

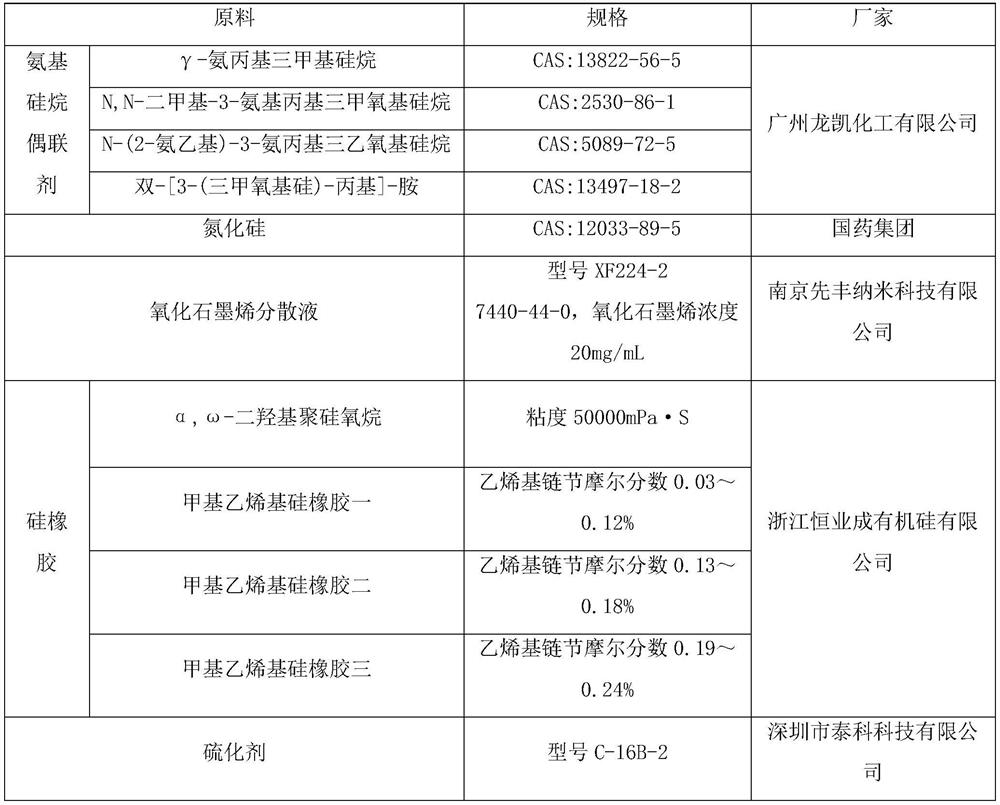

[0053]A modified conductive filler is different from Preparation Example 1 in that the weights of silicon nitride, γ-aminopropyltriethylsilane and graphene oxide dispersion are different, and the specific input amounts are shown in Table 2 below.

[0054] Table 2. Weights of silicon nitride, γ-aminopropyltriethylsilane, and graphene oxide

[0055] Preparation example Silicon Nitride / kg γ-Aminopropyltriethylsilane / kg Graphene oxide dispersion / L Preparation Example 1 40 2 200 Preparation Example 2 40 4 200 Preparation Example 3 40 6 200 Preparation Example 4 40 4 300 Preparation Example 5 40 4 400

preparation example 6-8

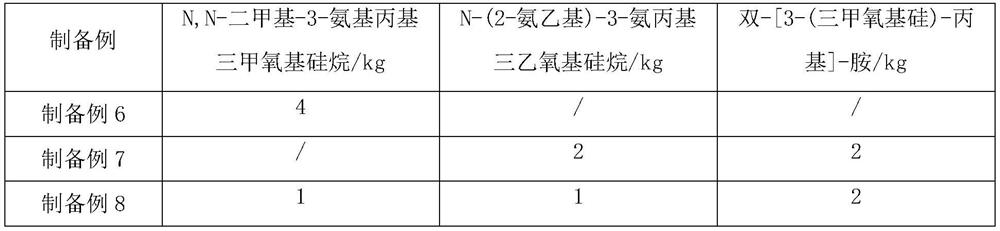

[0057] A modified conductive filler is different from Preparation Example 1 in that the selection of aminosilane coupling agent is different, and the specific selection is shown in Table 3 below.

[0058] Table 3. Selection of aminosilane coupling agents

[0059]

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com