Antibacterial film with bacterial cellulose loaded with gold nanosheets as well as preparation method and application of antibacterial film

A technology of bacterial cellulose film and bacterial cellulose, which is applied in the field of microbial technology and inorganic materials, can solve the problems of little progress in antibacterial and disease prevention, achieve good antibacterial ability and self-degradation ability, and the preparation method is simple and environmentally friendly. Effect of Tensile Strength and Elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The preparation of bacterial cellulose-loaded antibacterial films of gold nanosheets includes the following steps:

[0034] (1) Weigh a sample of 0.6-0.8g of bacterial cellulose and put it in a beaker, then add 100mL of 0.1mol NaoH solution, boil at 95°C for 2 hours, cool it to room temperature, the transparent solution becomes an opaque suspension , vacuum-dried for 24 hours to obtain a pure bacterial cellulose (BC) sample.

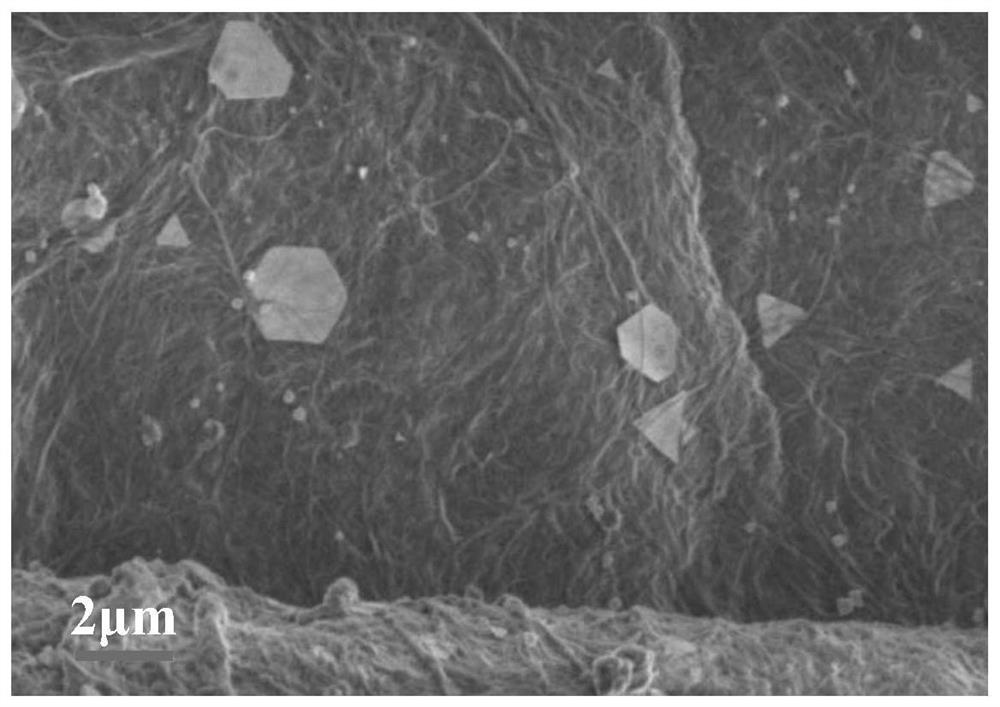

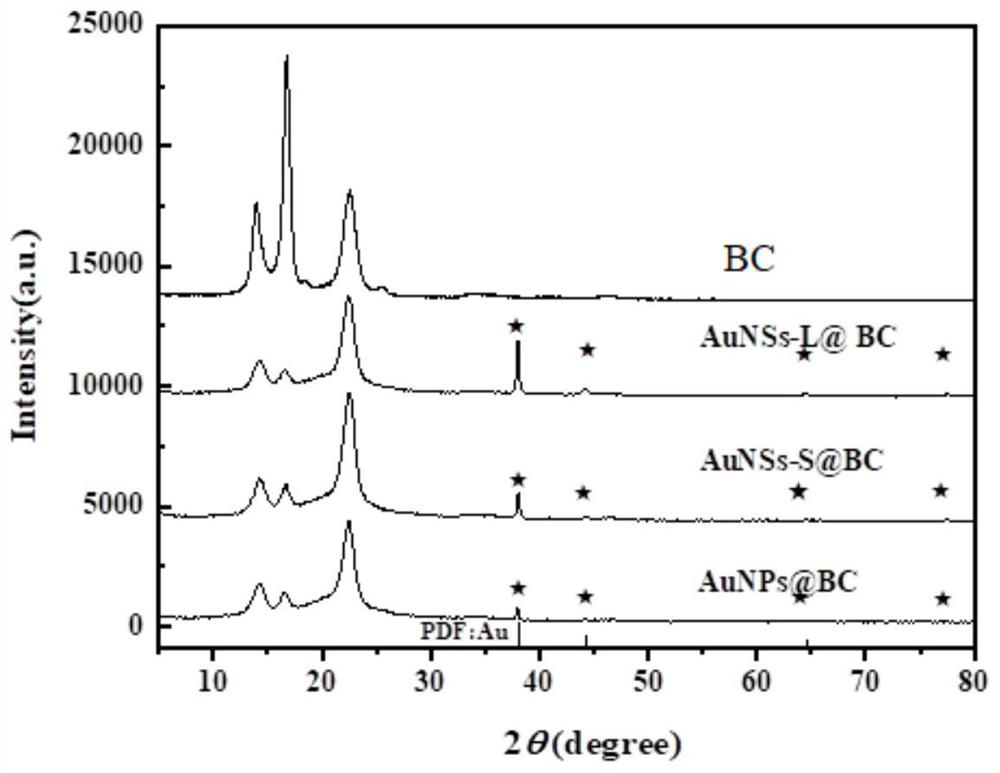

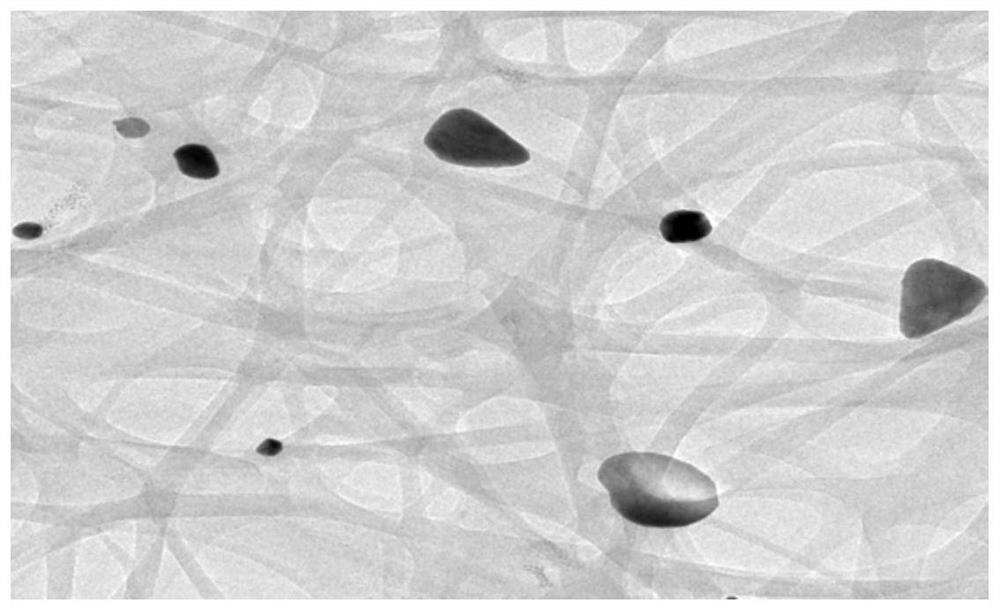

[0035] (2) Pipette the chloroauric acid solution 1mL, 2mL, 3.4mL of 10% with a pipette gun, transfer to the 10mL volumetric flask respectively, and configure the chloroauric acid solution of 30mM, 60mM, 100mM, the step ( 1) The pure bacterial cellulose sample was immersed in 30mM chloroauric acid solution and irradiated by ultraviolet light for 12h, denoted as AuNPs@BC; in 60mM chloroauric acid solution, irradiated by ultraviolet light for 12h, denoted as AuNSs-S@BC and 100mM chloroauric acid The ultraviolet light in the solution was irradiated f...

Embodiment 2

[0038] Place the AuNPs@BC, AuNSs-S@BC, and AuNSs-L@BC prepared in Example 1 in the solid medium containing the bacterial liquid, and incubate them in a constant temperature incubator for 24 hours at a temperature of 37°C and the shaking frequency of the incubator 78r / min, the results showed that the prepared AuNSs-S@BC had obvious antibacterial effect. See Figure 5, Bacterial cellulose-loaded gold nanosheet antimicrobial film (referred to as the antibacterial effect of AuNSs-S@BC) obtained by immersing the pure sample of bacterial cellulose in 60mM chloroauric acid solution and then irradiated for 12h. Figure 5 It can be seen from the figure that AuNSs-S@BC has good antibacterial effect and has obvious antibacterial zone.

Embodiment 3

[0040] The AuNSs@BC of Example 2 was placed in the solid medium containing the bacterial solution and incubated for 24 hours, was taken out, rinsed with deionized water and ethanol, and dried at 60°C to obtain a reusable AuNSs@BC. Carry out repeated experiments under the same conditions of embodiment two, the result proves that reusable still has better antibacterial effect, see Figure 6 , for the antibacterial effect of reusable AuNSs-S@BC after cleaning, from the attached Figure 6 It can be seen from the figure that it still has obvious antibacterial effect.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com