Preparation process of anti-wrinkle moisturizing lotion for dry skin

A moisturizing lotion and preparation process technology, applied in the field of skin care, can solve the problems that the liquid surface of the lotion is easily oxidized, the service life is lower than expected, and the anti-wrinkle and anti-oxidation are weak, so as to eliminate or relieve the greasy feeling, avoid air bubbles, prolong the The effect of the saved time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

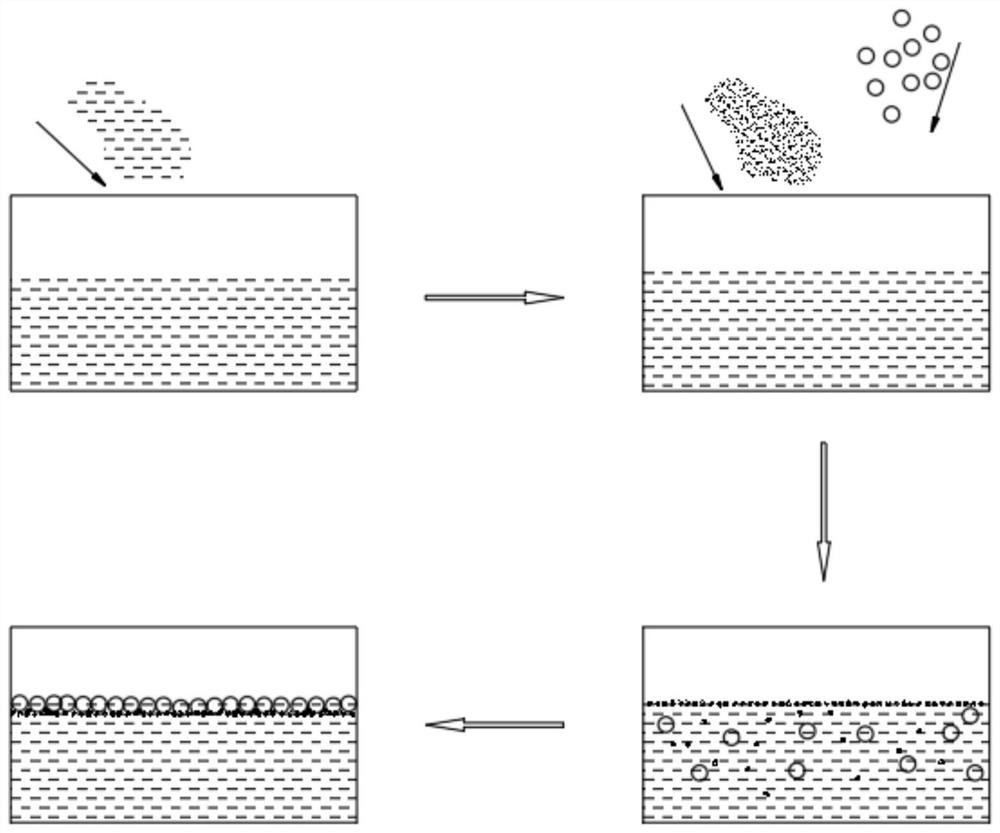

[0046] see figure 1 , a preparation process of anti-wrinkle moisturizing lotion for dry skin, comprising the following steps:

[0047] S1, weigh the liquid raw material and the solid raw material according to the mass parts respectively, and set aside;

[0048] S2. Stir and mix each liquid raw material at a low speed to obtain a mixed solution;

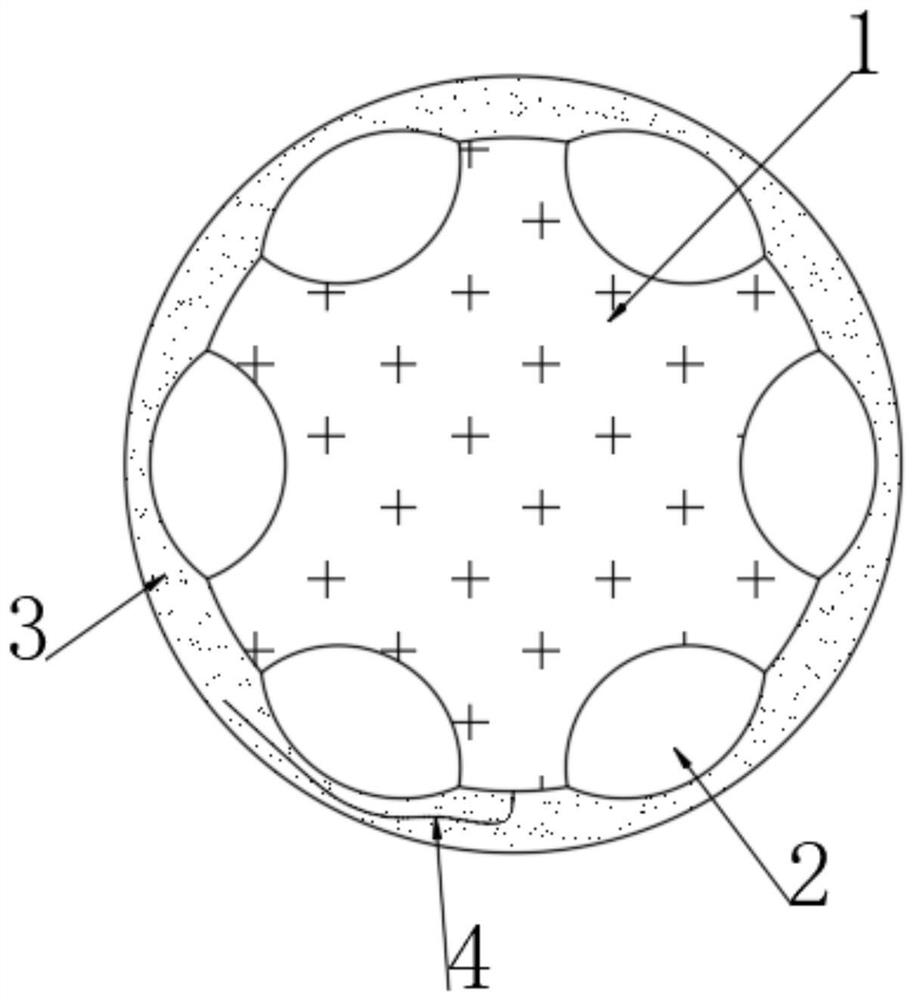

[0049] S3. Sprinkle powdered raw materials and suspended balls into the mixed liquid in turn, and stir continuously at low speed for 15-20 minutes to disperse the oil emulsion layer on the surface of suspended balls to form oil droplets, and combine powdered raw materials to make the powder The raw material floats up under the action of oil droplets and floats on the surface of the mixture;

[0050] S4. Afterwards, heat treatment is performed to slightly expand the suspended balls and accelerate their rise until the suspended balls float on the surface of the mixed solution to obtain a moisturizing emulsion.

[0051] The liquid raw...

Embodiment 2

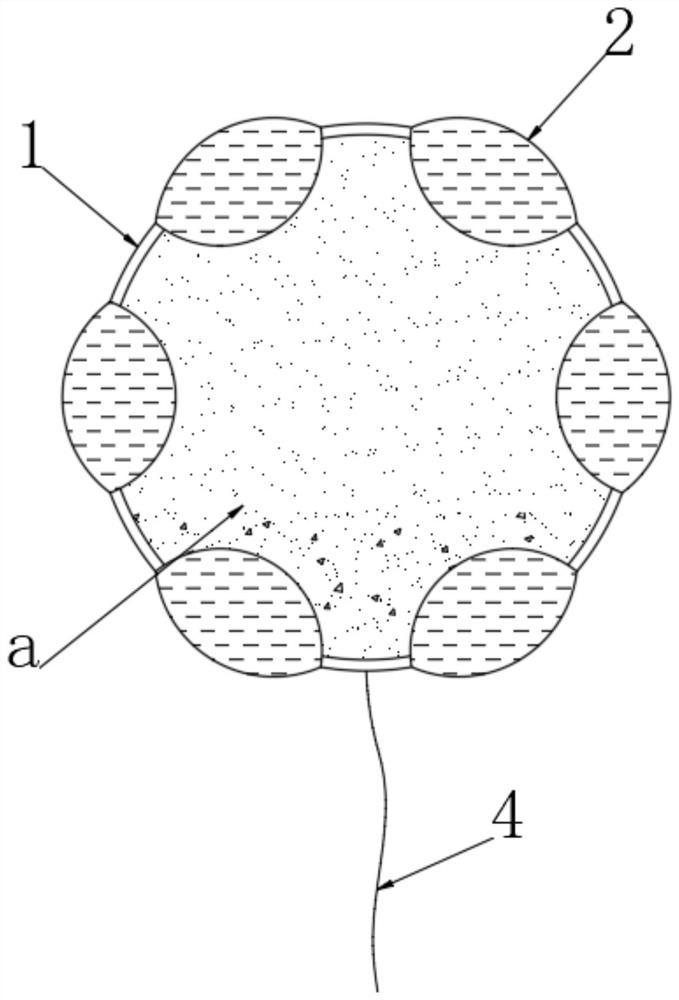

[0059] see Figure 7 , the embedding ball 2 is filled with inert gas, and the two states are toner and silica gel particles. The toner is filled in the material ball 1. When the ball is patted and rubbed, the amount of overflow is more, and the auxiliary moisturizing effect on the face is better. it is good.

[0060] The difference between this embodiment and embodiment 1 is mainly that the materials filled in the material ball 1 and the embedding ball 2 are different, and the rest of the content is consistent with the embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com