Efficient energy-saving heat pump continuous extraction and concentration equipment

A high-efficiency energy-saving, heat pump technology, applied in energy-saving heating/cooling, heat recovery systems, climate sustainability, etc., can solve the problems of inconvenient continuous feeding, waste of raw materials, inconvenient extraction of medicinal materials, etc., to shorten extraction time and accelerate dissolution , the effect of high concentration difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

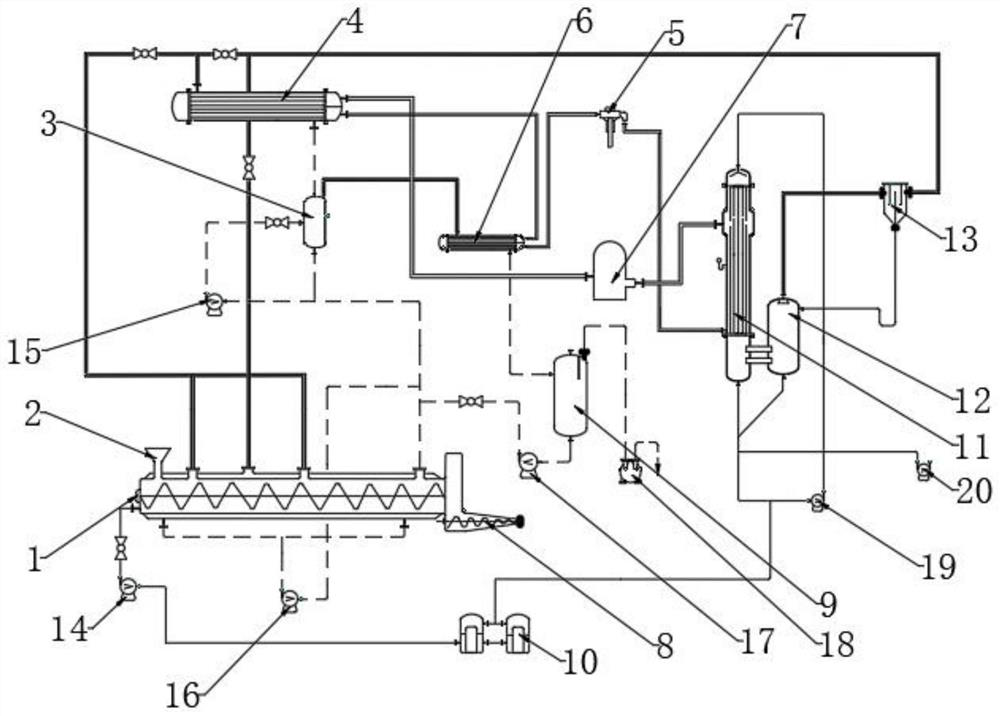

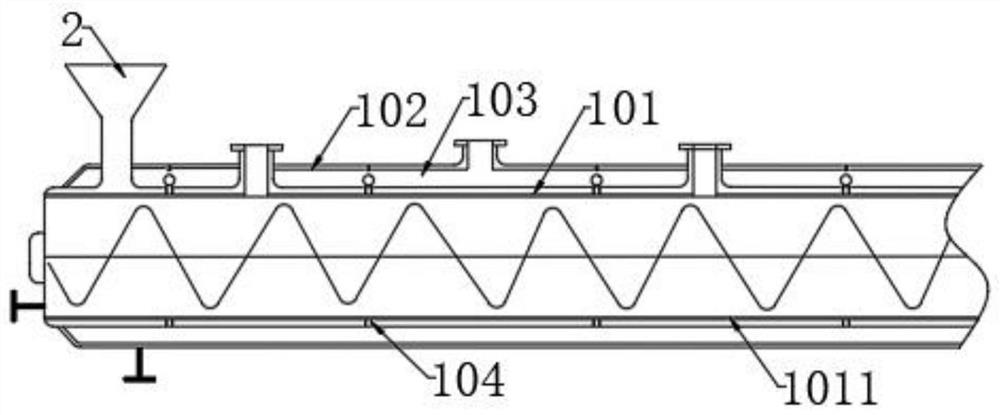

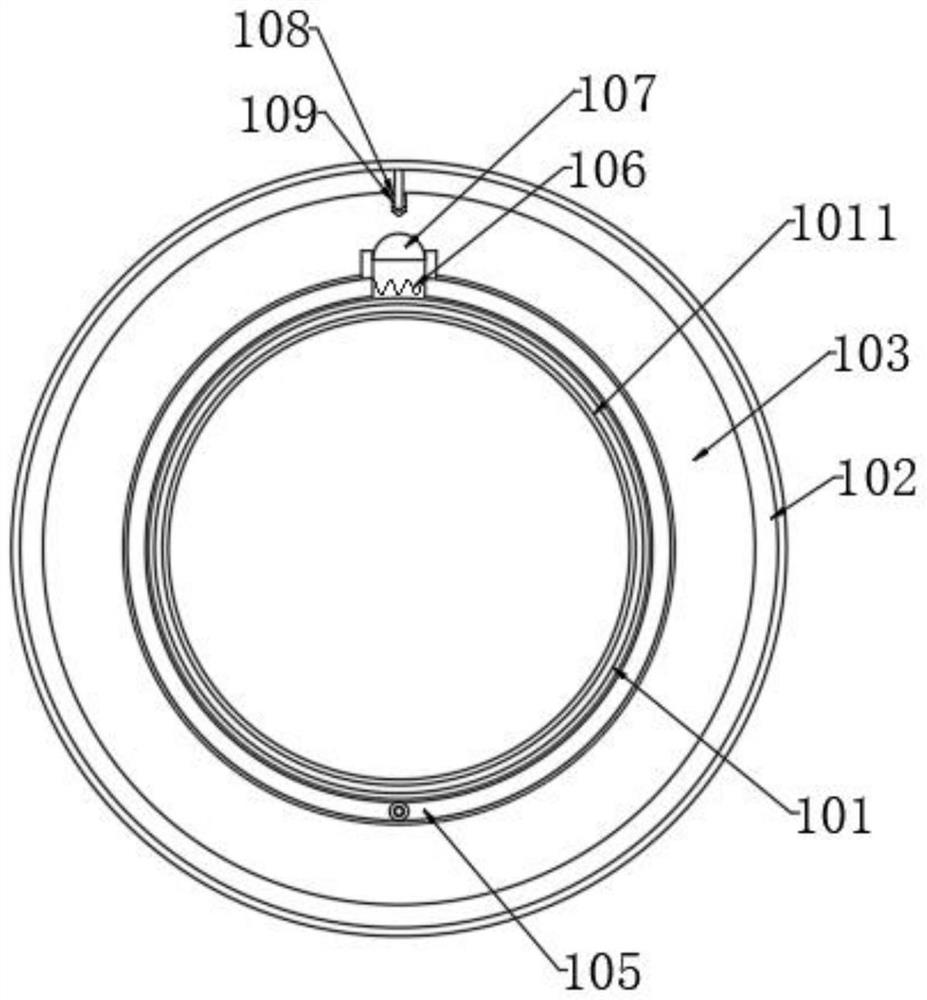

[0040] see figure 1 , a high-efficiency energy-saving heat pump continuous extraction and concentration equipment, including a continuous spiral extraction machine 1, the upper end of the continuous spiral extraction machine 1 is fixedly connected with a quantitative feeding bin 2, and the outer end of the continuous spiral extraction machine 1 is fixedly connected with a first vapor-liquid separator 3. The first vapor-liquid separator 3 communicates with the spiral continuous extractor 1, and the outer end of the first vapor-liquid separator 3 is fixedly connected with a working fluid condenser 4, and the working medium condenser 4 is connected to the spiral continuous extractor respectively. 1 and the first vapor-liquid separator 3 are connected, the outer end of the working fluid condenser 4 is fixedly connected with the working fluid cooler 6, and the outer end of the working fluid cooler 6 is fixedly connected with the electronic shut-off valve 5, and the working fluid con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com