Underground solid-containing heavy dirty oil tank and solid-containing heavy dirty oil delivery method

An oil tank and dirty oil technology, applied in separation methods, chemical instruments and methods, grease/oily substance/float removal devices, etc., can solve problems such as economic loss, impeller blockage, failure, etc. The effect of business economic loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

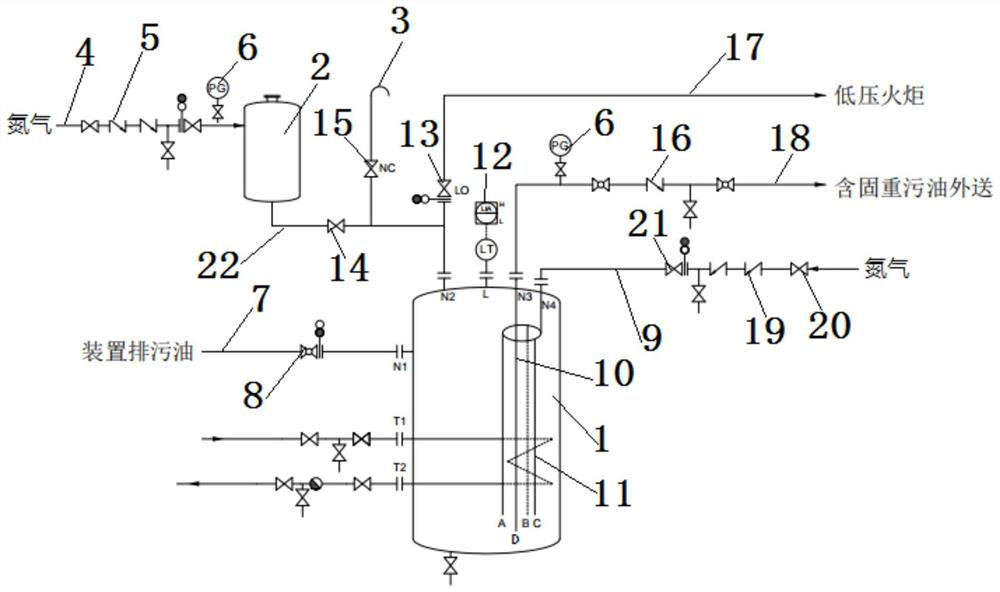

[0039] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0040] Such as figure 1 As shown, the present invention provides an underground heavy dirty oil tank containing solids, and practical application proves that the traditionally designed underground heavy dirty oil tank cannot satisfy the storage and transportation process operation of solid-containing, high-viscosity heavy dirty oil medium at all. In order to avoid many technical problems in the storage and transportation of solid-containing and high-viscosity medium dirty oil in traditional underground heavy-duty oil tanks, a special underground solid-containing heavy-duty oil tank has been designed according to relevant technical research. Its specific structure and operation control method It is very different from ordinary heavy dirty oil tanks, and the purpose is to overcome the clogging problem of solid-containing and high-viscosity media ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com