Preparation method of cyclic carbonate

A cyclocarbonate, dual-center technology, applied in the field of preparation of cyclocarbonate, can solve the problems of complex catalyst recovery, and achieve the effects of high-efficiency catalytic cycloaddition, high ligand concentration, and excellent swelling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

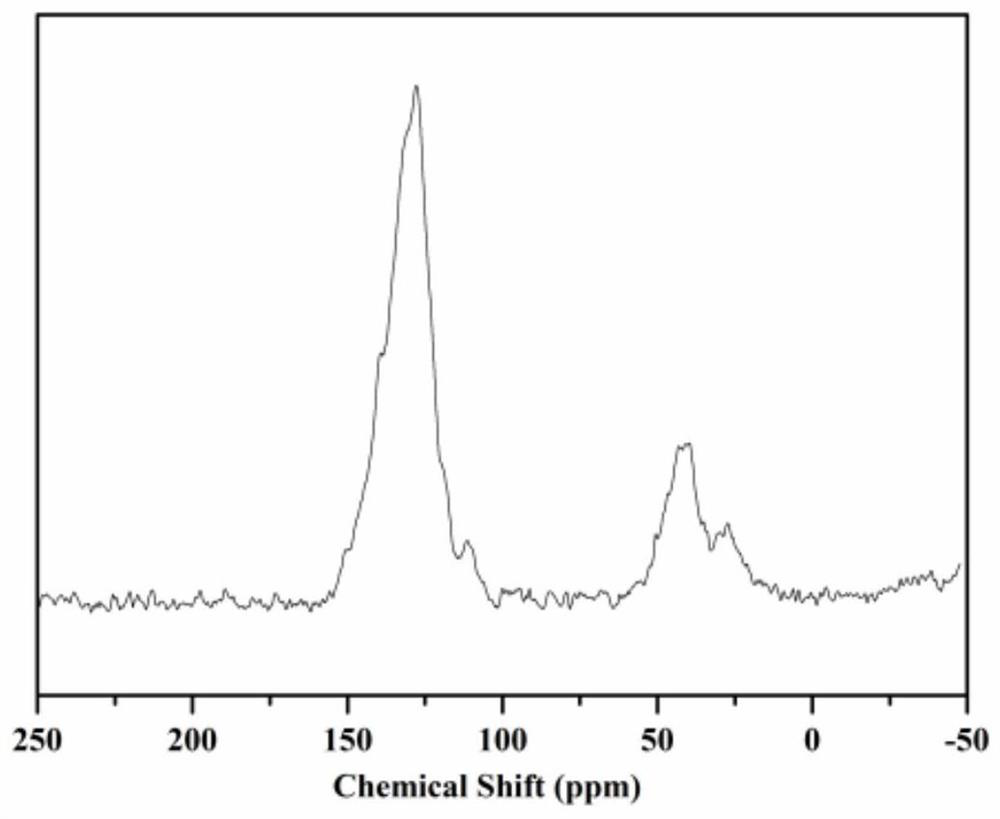

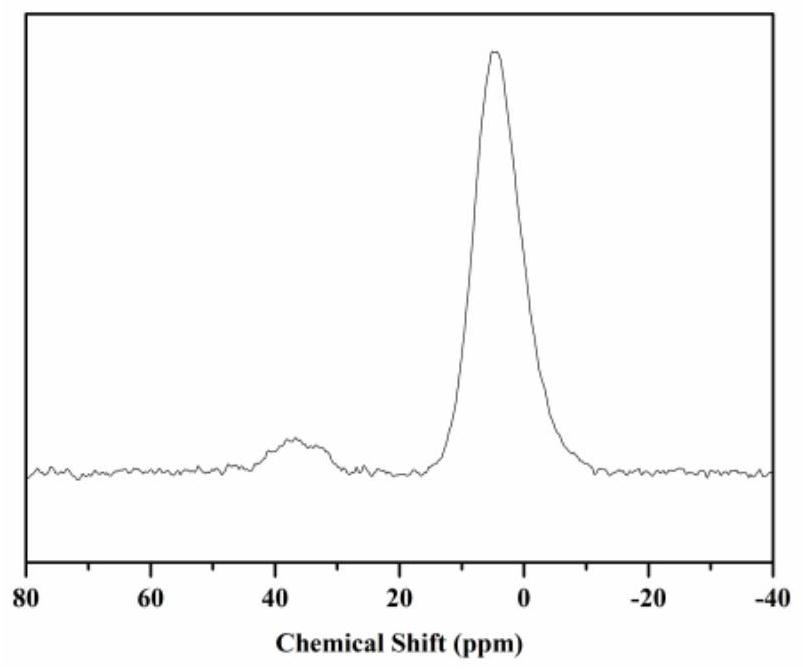

Image

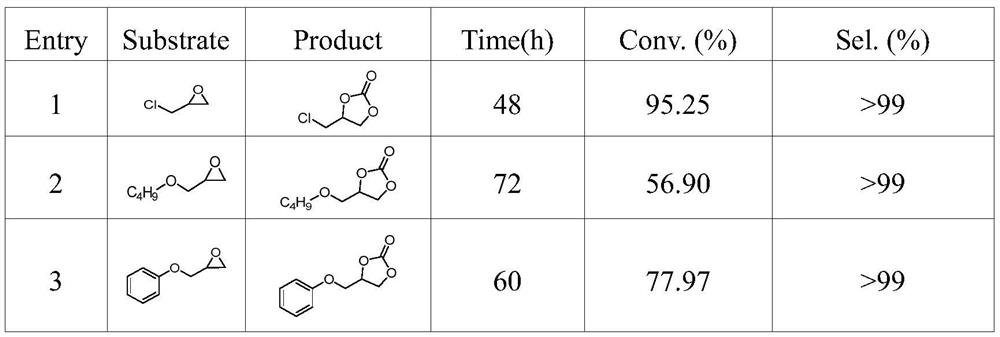

Examples

Embodiment 1

[0030] 1. Synthesis of Dual Center Porous Polymers:

[0031] Step 1, 4-(Diphenylphosphino)styrene (Ph 2 PSt) synthesis;

[0032] Using 4-bromostyrene and diphenylphosphine chloride as raw materials to prepare 4-(diphenylphosphino)styrene; the details are as follows:

[0033] 4-Bromostyrene was purified by distillation under reduced pressure before use; magnesium powder (1.5g, 62.5mmol) was added to a 300ml three-necked round-bottomed flask, dried under vacuum, and dried under N 2 Tetrahydrofuran (50ml) was added under the atmosphere, then 4-bromostyrene (6.6075g, 36.1mmol) was added dropwise through a dropping funnel, after the dropwise addition, stirring was continued at room temperature for two hours, and diphenyl chloride was added by the same operation. Phosphine (6.6120 g, 30.3 mmol) was reacted at room temperature overnight. After the reaction was stopped, the solution was quenched with saturated aqueous ammonium chloride solution (200 ml), extracted with ethyl acetat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com