Method for covering mulching film by extruding and casting PVA sol

A technology of extrusion casting and covering film, which is applied in the direction of botany equipment and methods, plant protection, application, etc., can solve the problems of inability to use, loss of strength, etc., improve moisture content, increase viscosity and water storage rate, and facilitate the realization of Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The preparation method of the modified starch slurry comprises the following steps: (1) Paste making: adding the starch into a sodium hydroxide solution with a pH of 8-9, mixing and stirring to form a starch slurry, and heating at 80-90° C. to form a paste-like starch Serum, the mass concentration of starch in the starch slurry is 80% to 90%; (2) Modification reaction: by weight ratio, in 100 parts of pasty starch slurry, add 20 parts of diisocyanate, 20-40 parts of acrylic acid hydroxyl Ethyl ester and 0.1-1 part of stannous octoate, then react at 75°C to 105°C for 1-5h to obtain modified starch slurry.

[0034] The starch is one or a combination of corn starch, thermoplastic starch, wood flour and potato starch.

Embodiment 1

[0037]A method for extruding and casting PVA sol to cover plastic film, comprising the steps of: (1) preparing modified starch slurry: first, adding cornstarch to a sodium hydroxide solution with a pH of 8, mixing and stirring to form a starch slurry, and heating at 80°C to form a starch slurry. Pasty starch slurry, the mass concentration of starch in the starch slurry is 80%; then, in the above-mentioned 100 parts of pasty starch slurry, add 20 parts of diisocyanate, 20 parts of hydroxyethyl acrylate and 0.1 part of octanoic acid in sequence stannous, then react at 75°C for 1h to obtain a modified starch slurry;

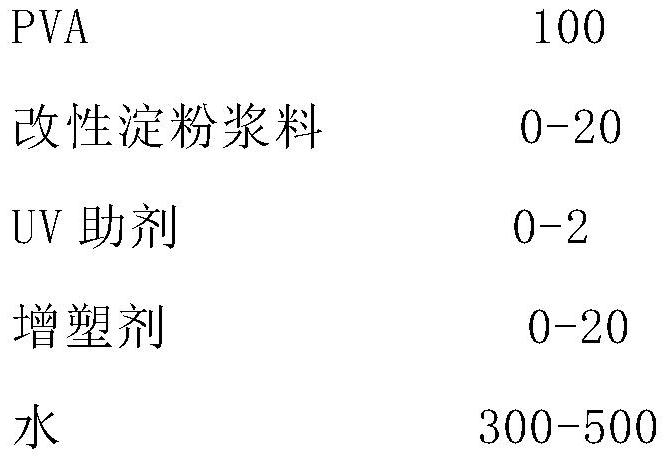

[0038] (2) Prepare PVA sol by the following mass parts:

[0039]

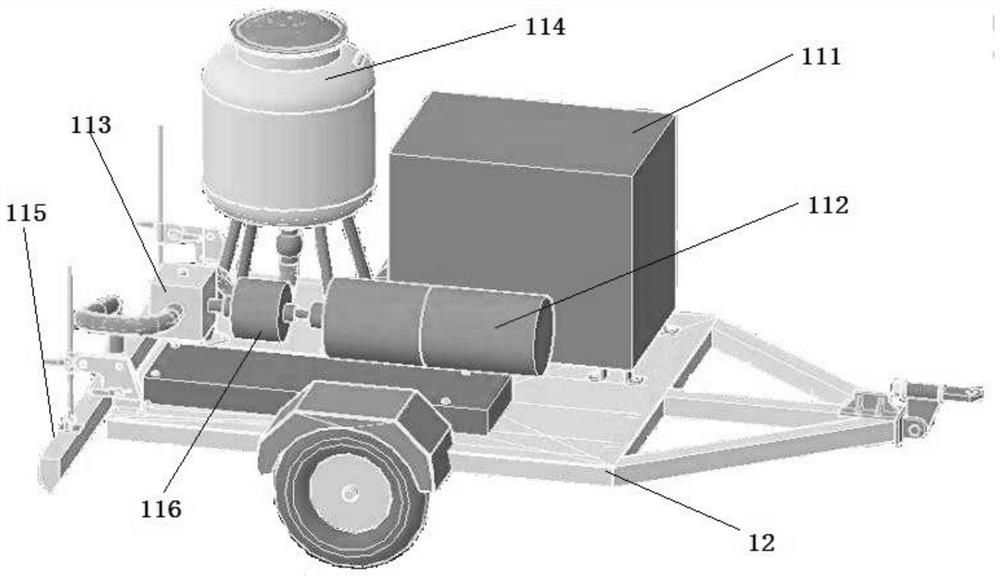

[0040] (3) Extrude and cast PVA sol to form a film with an extrusion cast film laminating machine, and directly lay the film on the surface of the field. The specific steps are: first, add the PVA sol to the storage tank 114, and start the diesel generator 111 , energize the heating jacket of the...

Embodiment 2

[0043] A method for extruding and casting PVA sol to cover plastic film, comprising the steps of: (1) preparing modified starch slurry: first, adding potato starch into a sodium hydroxide solution with a pH of 9, mixing and stirring to form a starch slurry, and heating at 90°C to form a starch slurry. Pasty starch slurry, the mass concentration of starch in the starch slurry is 90%; then, in the above-mentioned 100 parts of pasty starch slurry, add 20 parts of diisocyanate, 40 parts of hydroxyethyl acrylate and 1 part of octanoic acid in sequence stannous, then react at 105°C for 5h to obtain modified starch slurry;

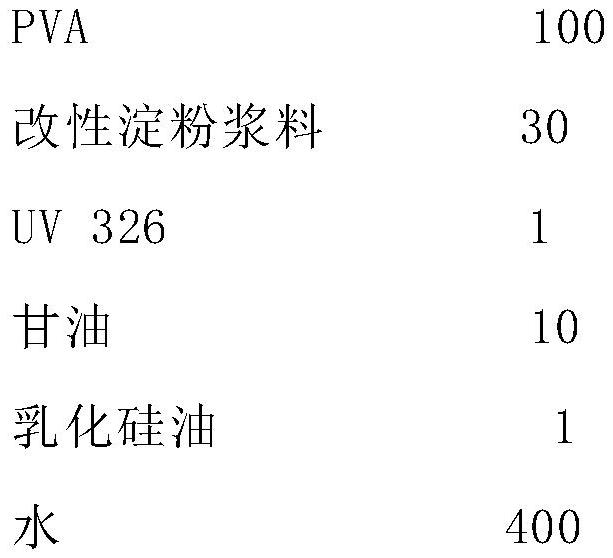

[0044] (2) Prepare PVA sol by the following mass parts:

[0045]

[0046] (3) Extrude and cast PVA sol to form a film with an extrusion cast film laminating machine, and directly lay the film on the surface of the field. The specific steps are: first, add the PVA sol to the storage tank 114, and start the diesel generator 111 , energize the heating jacket of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com