Toughening modification preparation method of benzoxazine

A benzoxazine, toughening modification technology, applied in the field of benzoxazine toughening modification preparation, composite materials, can solve the problems of reduced toughness, poor film formation, poor processing performance, etc. Improved film properties, simple curing process, and improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

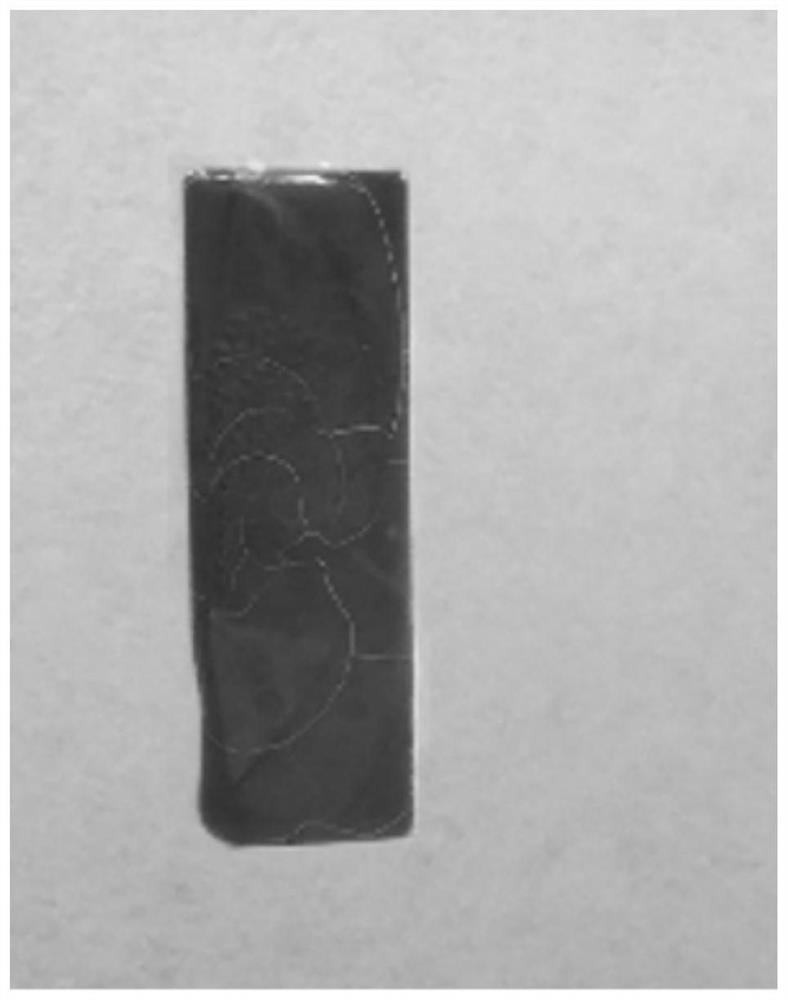

[0032] Embodiment 1 (PHT / PHB-a)

[0033] Such as Figures 1 to 4 As shown, this example provides a preparation method for toughening and modifying benzoxazine. mmol), 3-phenyl-6-formyl-3,4-dihydro-2H-1,3-benzoxazine (PHB-a) (0.32mmol) and formaldehyde (2mmol) were added to a glass bottle, and Add 2.0ml of N-methylpyrrolidone (NMP) as a solvent, stir the mixed solution at room temperature until it is completely dissolved, filter it and pour it on a clean glass plate, react the blended system at 50°C for 12h, and react at 200°C for 2h for curing to obtain Dark red blend polymer interpenetrating network, the interpenetrating network has good mechanical properties and thermal properties: nitrogen atmosphere, 800 ℃ residual carbon were 45.4%, 53.1%, 59.2%, elongation at break 5.31%, 8.47% , 6.43%, tensile strength of 106.6MPa, 105.9MPa, 97.5MPa.

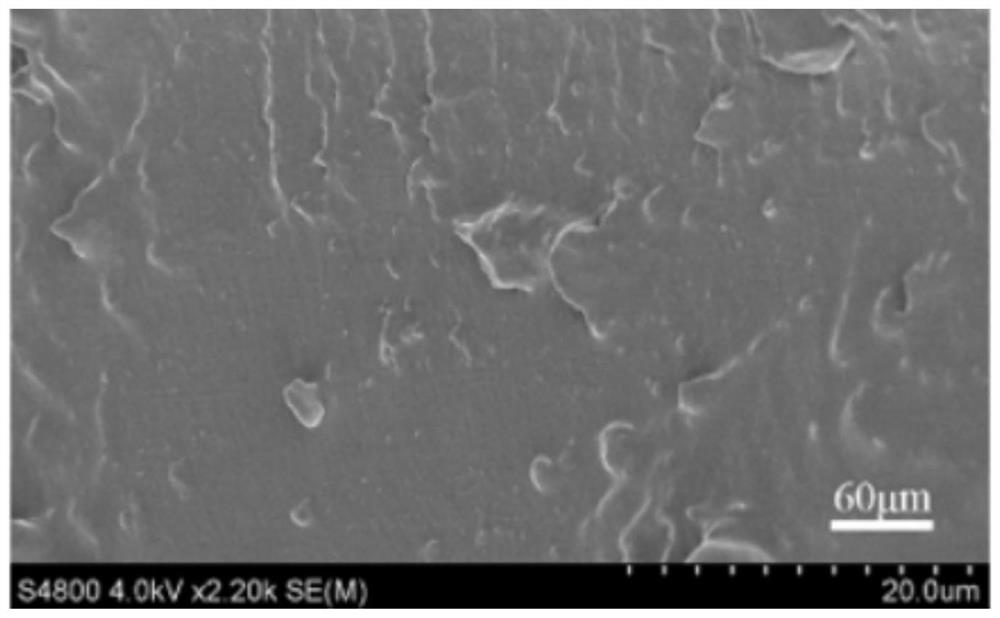

[0034] from figure 2 It was found that the resin was too brittle to form a film; from image 3 It can be found that the cross-sect...

Embodiment 2

[0037] Example 2 (PHT / bis-M)

[0038]This example provides a preparation method for the toughening modification of benzoxazine. 1,3-bis(4-aminophenoxy)benzene[4,4'-(1,3-Phenylenedioxy)dianiline](0.4mmol), Bis(4-phenyl-3,4-dihydro-2H-1,3-benzoxazine)methane (bis-M) (0.16mmol) and formaldehyde (2mmol) were added to a glass bottle, and 2.0mL N- Methylpyrrolidone (NMP) was used as a solvent, and the mixed solution was stirred at room temperature until it was completely dissolved. After filtering, it was poured onto a clean glass plate. The blend system was reacted at 80°C for 6h, and then solidified at 180°C for 6h to obtain a dark red benzoxan In the oxazine system, the residual carbon at 800°C is 42.2%, 45.1%, 54.8%, the elongation at break is 6.40%, 7.47%, 10.5%, and the tensile strength is 101.6MPa, 121.9MPa, 122.5MPa.

[0039] The reaction formula involved in embodiment 2 is as follows:

[0040]

Embodiment 3

[0041] Example 3 (PHT / bis-MO)

[0042] This example provides a preparation method for the toughening modification of benzoxazine. 1,3-bis(4-aminophenoxy)benzene[4,4'-(1,3-Phenylenedioxy)dianiline](0.4mmol), Add bis(4-phenyl-3,4-dihydro-2H-1,3-benzoxazine)methanone (bis-MO) (1.28mmol) and formaldehyde (2mmol) into a glass bottle, and add 2.0ml N -Methylpyrrolidone (NMP) was used as a solvent, the mixed solution was stirred at room temperature until it was completely dissolved, filtered and poured onto a clean glass plate, the blend system was reacted at 60°C for 10h, and reacted at 190°C for 4h to solidify to obtain a dark red benzo Oxazine system, nitrogen atmosphere, 800 ℃ residual carbon is 46.4%, 48.7%, 54.8%, elongation at break is 7.02%, 8.13%, 9.27%, tensile strength is 98.2MPa, 116.3MPa, 114.8MPa.

[0043] The reaction formula involved in embodiment 3 is as follows:

[0044]

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com