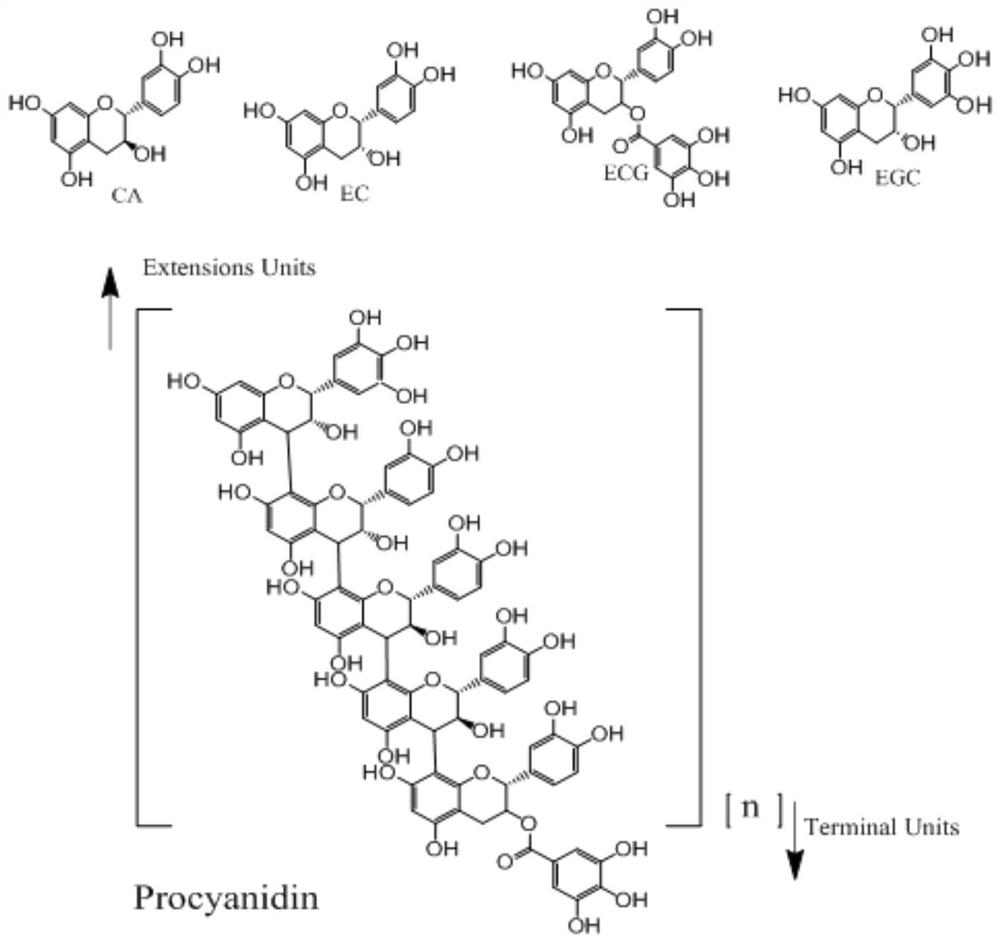

Application of lyase in preparation of oligomeric proanthocyanidins and method for preparing oligomeric proanthocyanidins through combination of steam explosion and lyase

A low-polymerization proanthocyanidin and high-polymerization proanthocyanidin technology is applied in the direction of fermentation, which can solve the problems of low substrate conversion rate, complex process, environmental pollution, etc., and achieve the effect of mild reaction conditions, high extraction rate and simple degradation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Add 130-mesh grape seed powder into deionized water and soak for 35 minutes. Then, the treated grape seed powder was subjected to steam explosion treatment, maintained at a pressure of 3.0MPa for 105s, and then the pressure was released within 0.00087s to complete the explosion. After blasting, collect blasting samples. Add 60mL of petroleum ether to 3.00g of the exploded grape seed sample, and degrease for 5h under the shaking condition of 150rpm. After degreasing, petroleum ether was removed by evaporation under reduced pressure to obtain a sample of defatted grape seed powder. Take 1.00g of degreased grape seed sample and place it in 20mL of acetone:ultrapure water:acetic acid solution with a volume ratio of 75:24.5:0.5, and ultrasonicate for 23min at 30°C and 20kHZ. After the sonication, shake for 1.5 h at room temperature under light-shielding conditions, the content of highly aggregated proanthocyanidins in the crude extract is 24.4%. After calculation, the ext...

Embodiment 2

[0042] Add 60-mesh grape seed powder into deionized water and soak for 20 minutes. Then, the treated grape seed powder was subjected to steam explosion treatment, maintained at a pressure of 2.5MPa for 90s, and then the pressure was released within 0.00087s to complete the explosion. After blasting, collect blasting samples. Add 20mL of petroleum ether to 1.00g of the exploded grape seed sample, and degrease for 2h under the shaking condition of 50rpm. After degreasing, petroleum ether was removed by evaporation under reduced pressure to obtain a sample of defatted grape seed powder. Take 1.00g of defatted grape seed sample and place it in 15mL of acetone:ultrapure water:acetic acid solution with a volume ratio of 72.5:24.5:3, and ultrasonicate for 15min at 20°C and 10kHZ. After the sonication, shake for 1 h at room temperature under light-shielding conditions, the content of highly aggregated proanthocyanidins in the crude extract is 21.4%. After calculation, the extractio...

Embodiment 3

[0044] Add 200-mesh grape seed powder into deionized water and soak for 50 minutes. Then, the treated grape seed powder was subjected to steam explosion treatment, maintained at a pressure of 3.5MPa for 120s, and then the pressure was released within 0.00087s to complete the explosion. After blasting, collect blasting samples. Add 100mL of petroleum ether to 5.00g of the blasted grape seed sample, and degrease for 8h under the shaking condition of 250rpm. After degreasing, petroleum ether was removed by evaporation under reduced pressure to obtain a sample of defatted grape seed powder. Take 3.00g of defatted grape seed samples and place them in 30mL of acetone:ultrapure water:acetic acid solution with a volume ratio of 73:26.5:0.5, and ultrasonicate for 30min at 35°C and 30kHZ. After the sonication, shake for 2 hours at room temperature under light-shielding conditions, the content of highly aggregated proanthocyanidins in the crude extract is 24.4%. After calculation, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com